Manual 2100-419E

Page

33 of 48

START UP PROCEDURE FOR CLOSED

LOOP SYSTEM

1. Be sure main power to the unit is OFF at disconnect.

2. Set thermostat system switch to OFF, fan switch to

AUTO.

3. Move main power disconnect to ON. Except as

required for safety while servicing,

Do not open the

unit disconnect switch.

4. Check system air flow for obstructions.

A. Move thermostat fan switch to ON. Blower

runs.

B. Be sure all registers and grilles are open.

C. Move thermostat fan switch to AUTO. Blowing

should stop.

5. Flush, fill and pressurize the closed loop system as

outlined in manual 2100-099.

6. Fully open the manual inlet and outlet valves. Start

the loop pump module circulator(s) and check for

proper operation. If circulator(s) are not operating,

turn off power and diagnose the problem.

7. Check fluid flow using a direct reading flow meter

or a single water pressure gauge, measure the

pressure drop at the pressure/temperature plugs

across the water coil. Compare the measurement

with flow versus pressure drop table to determine

the actual flow rate. If the flow rate is too low,

recheck the selection of the loop pump module

model for sufficient capacity. If the module

selection is correct, there is probably trapped air or a

restriction in the piping circuit.

8. Start the unit in cooling mode. By moving the

thermostat switch to cool, fan should be set for

AUTO.

9. Check the system refrigerant pressures against the

cooling refrigerant pressure table in the installation

manual for rated water flow and entering water

temperatures. If the refrigerant pressures do not

match, check for air flow problem then refrigeration

system problem.

10. Switch the unit to the heating mode. By moving the

thermostat switch to heat, fan should be set for

AUTO.

11. Check the refrigerant system pressures against the

heating refrigerant pressure table in installation

manual. Once again, if they do not match, check for

air flow problems and then refrigeration system

problems.

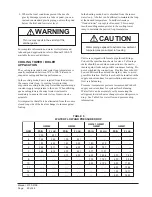

NOTE: If a charge problem is determined (high

or low):

A. Check for possible refrigerant leaks.

B. Recover all remaining refrigerant from unit and

repair leak.

C. Evacuate unit down to 29 inches of vacuum

D. Recharge the unit with refrigerant by weight.

This is the only way to insure a proper charge.

FIGURE 21

WATER TEMPERATURE and PRESSURE PROCEDURE

DIAL FACE PRESSURE GAUGE

WITH GAUGE ADAPTOR

THERMOMETER

WATER COIL CONNECTION

AT HEAT PUMP

TEST PLUG CAP

PETE’S TEST PLUG

UNION

MIS-1637

Содержание QW242

Страница 6: ...Manual 2100 419E Page 6 of 48 FIGURE 1 UNIT DIMENSIONS ...

Страница 9: ...Manual 2100 419E Page 9 of 48 FIGURE 4 INSTALLATION OF UNIT THROUGH WALL WITH WALL SLEEVE MIS 1564 ...

Страница 21: ...Manual 2100 419E Page 21 of 48 FIGURE 15 REMOTE THERMOSTAT WIRING DIAGRAM X OPTION ...

Страница 22: ...Manual 2100 419E Page 22 of 48 FIGURE 16 REMOTE THERMOSTAT WIRING DIAGRAM A THERMOSTAT OPTION 4102 021A ...

Страница 23: ...Manual 2100 419E Page 23 of 48 4102 022C FIGURE 17 REMOTE THERMOSTAT WIRING DIAGRAM D THERMOSTAT OPTION ...

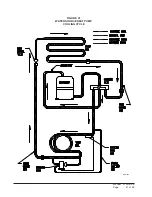

Страница 41: ...Manual 2100 419E Page 41 of 48 FIGURE 27 WATER SOURCE HEAT PUMP COOLING CYCLE MIS 329 ...

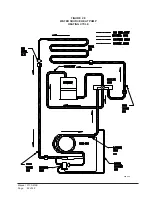

Страница 42: ...Manual 2100 419E Page 42 of 48 FIGURE 28 WATER SOURCE HEAT PUMP HEATING CYCLE MIS 328 ...