5

tubing as opposed to nylon tubing. This is because nylon tubing tends to crimp shut when

it is bent. To remove the Unclamp Supply Line for service, make sure the air pressure is

discharged, then while pushing inward on the fitting's elastic ring, simultaneously pull the

tubing out. Cover or plug the self-locking fitting any time the Unclamp Supply Line is not

connected. This will keep contaminants from entering.

CLAMPING HOUSING

UNCLAMP AIR

PORT R 1/8 (METRIC)

FEEDBACK CONNECTOR

POWER CONNECTOR

MOTOR COOLING

PORTS R 1/8 (METRIC)

MOTOR HOUSING

30 TAPER MOTOR SHAFT

Printed Colors – Front:

Requester:

Marnie Cleveland

Creator:

deZinnia_25417

File Name:

External Features.ai

Structure #:

Illustration

Date:

04/24/19

This artwork has been created as requested by 3M. 3M is responsible for the artwork

AS APPROVED and assumes full responsibility for its correctness.

Scale:

1 Inch

Figure 8. External Features

Electrical Connections

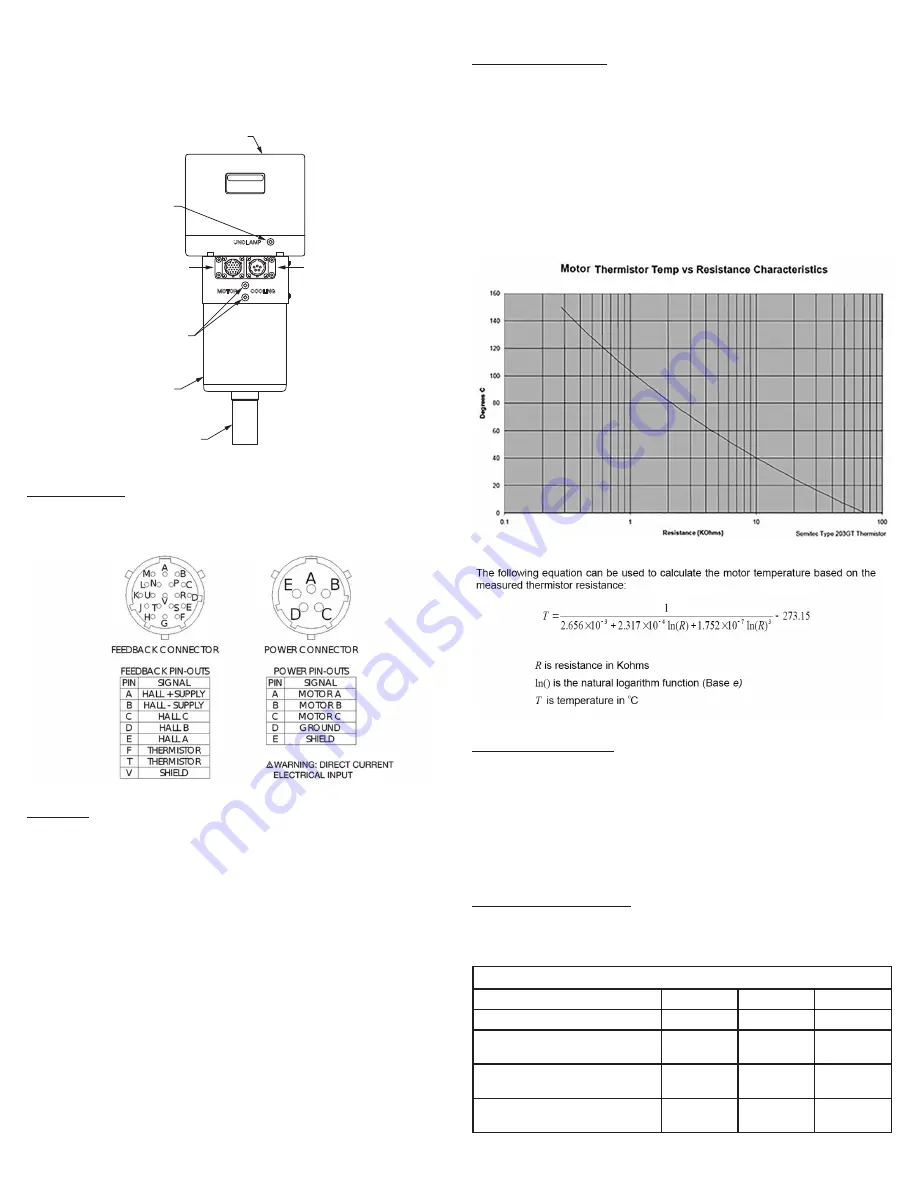

The Servo Motors have two electrical connections, the Motor Power and Motor Feedback (See

Figure 8). The Motor Power and Motor Feedback connectors are shown in Figure 9. The collet

release mechanism relies solely on air pressure to operate; it requires no electrical connections.

Figure 9. Electrical Connector Pin-outs

Motor Cooling

The Servo Motors require water cooling. Each motor is designed to operate below a

temperature of 176°F (80°C). The optimal motor temperature range is 122-140°F (50-60°C).

The motors contain cooling channels in the Motor Housing surrounding the motor stator.

These channels allow efficient removal of the heat. The coolant enters and exits the Motor

Housing through two Motor Cooling Ports as shown in Figure 8. Either of these Motor Cooling

Ports can be used as an input, the other would then become an output. A closed-loop water

cooling system must be used and requires a separate cooling unit that circulates water

through the Motor Housing to remove the heat. All of the coolant is recirculated in the system,

and no continuous supply or discharge is required. A mixture of pure distilled water and a

corrosion inhibitor is required such as DowTherm SR-1, or equivalent. Typical cooling units

are comprised of a pump, water to air heat exchanger, and fan. These units are commercially

available from several manufacturers (e.g., Miller Coolmate 3, www.millerwelds.com). The

cooling unit should be sized based on the motor power output of 3.0 hp (2.2 kW) or 5.0

hp (3.7 kW) with an overall motor efficiency of 90% and the motor load conditions. It is

recommended to constantly monitor the motor temperature during operation to ensure that it

does not overheat.

NOTE: The life of the motor is directly related to the operational temperature, so proper

cooling is critical.

Two 1/4” and 6 mm diameter tube push-lock fittings are provided for installation in the Motor

Cooling Ports. Remove the shipping plugs and install the desired size push-lock fittings. If

another type of fitting is needed, replace the existing fitting with a fitting having an R 1/8

(Metric) thread. Be sure to use a thread seal product and do not overtighten the fitting.

Monitoring Motor Temperature

The Servo Motors are designed to operate below a temperature of 176°F (80°C) and within an

optimal range of 122-140°F (50-60°C). In many situations it is desirable to monitor the internal

motor temperature to ensure that the maximum temperature rating is not exceeded, and that

the optimal temperature range is maintained. To facilitate this, each motor has a thermistor

that is embedded in the motor windings. The thermistor connection is provided on the Motor

Feedback Connector as shown in Figure 9. The thermistor temperature signal is a logarithmic

function of the output resistance. The graph shown in Figure 10 illustrates the internal motor

temperature verses the thermistor output resistance. In the graph, a temperature of 176°F

(80°C) corresponds to a resistance of 2000 ohms. If the thermistor indicates a resistance of

less than 2000 ohms then the motor should be immediately shut down before thermal damage

occurs. The motor also contains a thermal cutoff switch. If the temperature exceeds 212°F

(100°C) the motor will stop running until it has cooled off. This feature should not be used to

control the motor temperature. The thermal cutoff is designed to operate only when all other

precautions have failed.

Figure 10. Thermistor Chart

Figure 11. Temperature - Resistance Equation

Motor Acceleration/Deceleration

Servo Motors have the ability to start and stop very quickly. As long as the motor does not

overheat or the amplifier exceed the allowable current input, the motor will continue to

operate. The problem is that the motor and amplifier can experience excessive current spikes

with rapid acceleration and deceleration. Media or tooling with a large mass or large diameter

(i.e., high moment of inertia) only increases the current surge. The amount of time allowed

to reach the desired speed or stop will directly affect the life of the motor. 3M recommends a

smooth, linear velocity ramp with a minimum period of one second be used to accelerate to

full speed or to decelerate to zero speed. The minimum one-second-acceleration period must

be increased if larger, higher inertia tools are used to prevent servo amplifier faults and avoid

long-term damage.

Preventative Maintenance Schedule

It is highly recommended to adhere to the preventative maintenance schedule in order to help

extend the longevity of the equipment. Failing to do so could cause a loss in functionality as

well as a decrease in product life.

3M SPINDLES

Maintenance

Weekly

Monthly

3 Months

Remove chips from the ID of the shaft

X

Remove debris from spindle/spindle

housing

X

Check that the connectors are not bent/

damaged

X

Check for flow in the motor cooling and

unclamp ports

X