4

3M 06531

3M 06532

Figure 2. Spindle Motor Perpendicular-Axis Configuration

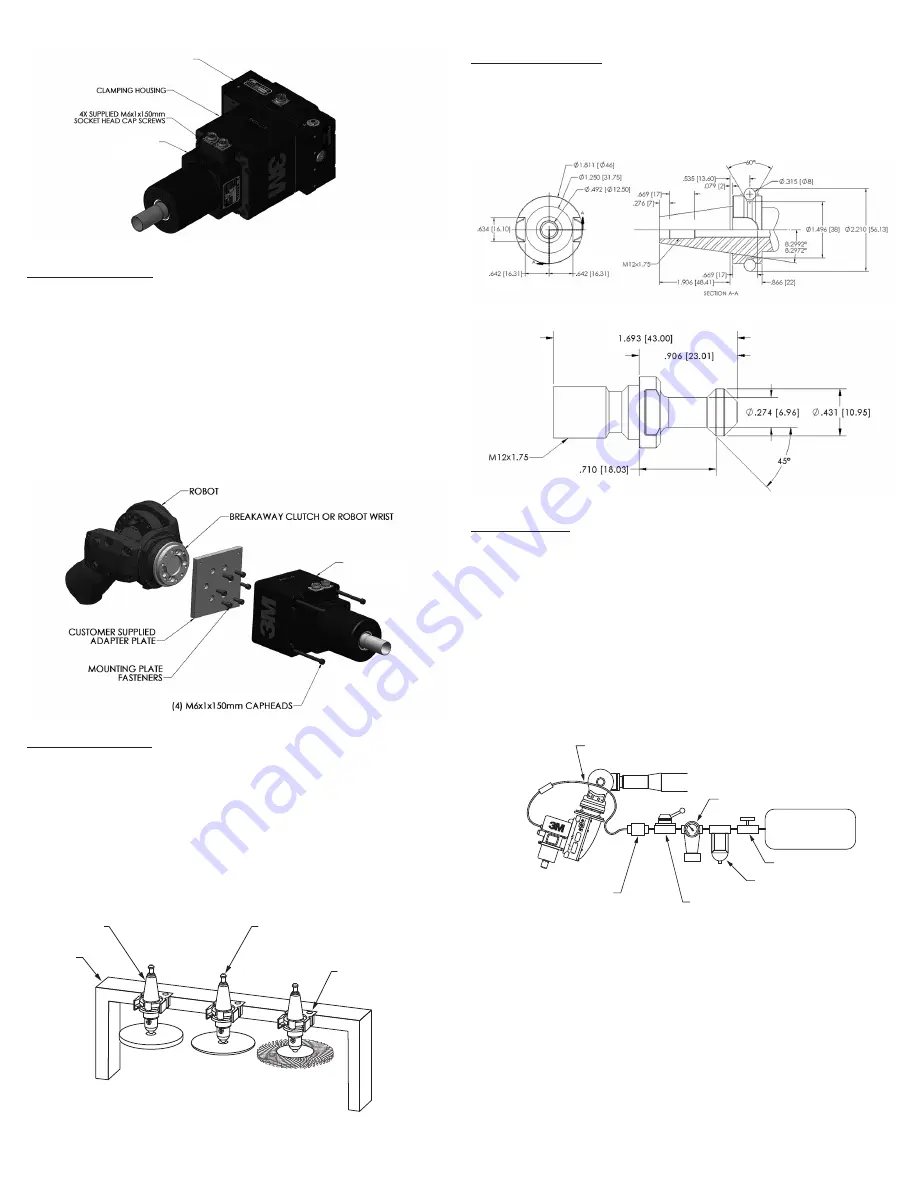

Mounting Directly to a Robot

For some processes compliance and force control are not required. The tools can be mounted

directly to the robot, in these cases, and the system can be operated in position mode. This

robotic system is equivalent to a 5-axis machining center with a very large work volume and

lower positional accuracy. Certain product types and processes are well suited for a Robotic

Machining Center (RMC). The tools can be attached to the Robot Mounting Flange using a

customer supplied Mounting Plate. For direct mounting it is recommended that a Breakaway

Clutch is installed. The Breakaway Clutch will help protect the motor in the event of a robot

crash. Loads on the motor shaft of over 300 lb (136 kg) radially and 150 (68 kg) axially will

damage the bearings.

To mount the tool, first attach the customer supplied Mounting Plate to the Robot Mounting

Flange or to the Breakaway Clutch, per the manufacturer’s specifications. Once the Mounting

Plate is secured, place the tool against the Mounting Plate and install four (4) M6x1x145mm

Socket Head Cap Screws. (See Figure 3.) Tighten the fasteners to the torque specified in the

Technical Specifications Section.

3M 06531

3M 06532

Figure 3. Spindle Motor Direct Mounting

Media and Tool Presentation

Media and tool presentation refers to how various discs, drill bits, router bits, etc. are

presented so that a robot may maneuver the motor into position to grasp the Toolholder

reliably. It is ultimately the user’s responsibility to provide a means to present the media and/

or tooling in an effective and repeatable way for a given application.

As shown in Figure 4, many types of media and tools may be accurately located in a Tool

Cradle. A robot can then be taught approach paths and docking locations to reliably bring the

motor down over the Toolholders and grasp them. The motor’s Collapsing Collet allows

0.015 in. (0.38 mm) diametrical clearance around the Toolholder when open. The Toolholder

must have a taper that mates to a Tapered Holder mounted in the Tool Cradle. The Tapered

Holder requires a slot to allow the Toolholder to pass through. This same method is applicable

to the motor’s design.

BT30 TOOLHOLDER

BT30 TOOLHOLDER GRIPPER

BT30 RETENTION KNOB

TOOL RACK

Printed Colors – Front:

Requester:

Marnie Cleveland

Creator:

deZinnia_25417

File Name:

Sample Media and Tooling Presentation Scheme.ai

Structure #:

Illustration

Date:

04/24/19

This artwork has been created as requested by 3M. 3M is responsible for the artwork

AS APPROVED and assumes full responsibility for its correctness.

Scale:

1 Inch

Figure 4. Sample Media and Tooling Presentation Scheme

BT30 Toolholder Specification

The 3M Model 06531 and 06532 motors are designed to grip a BT30 Toolholder. The BT30

Toolholder is a standard machine tool style and may be purchased from 3M (Part Number

06534, 5/8-11 X .48IN BT30 TOOLHOLDER HTC): The Customer can also make their own BT30

Toolholder to handle special media (See Figure 5 for Toolholder dimensions). The Toolholder

must be equipped with a Parlec (www.parlec.com) retention knob, part number 3003TRK, or

equivalent. Figure 6 shows the Parlec retention knob with the required dimensions.

Figure 5. STC-BT30 Toolholder Dimensions

Figure 6. BT30 Retention Knob

Pneumatic Connection

The Tool Changing function of the motor requires a dry, non-lubricated, filtered air supply,

with a minimum pressure of 90 psi (6.2 bar) and a maximum pressure of 100 psi (6.9 bar).

Failure to provide supply air to these specifications can degrade performance and will void any

warranty repairs concerning pneumatic components. If the supply air pressure is too low then

the unit will be unable to fully release the Toolholder. Exceeding the maximum air pressure

could result in permanent damage to the Tool Changing function. The pneumatic supply system

should be configured as shown in Figure 7. A manual or electrically operated valve may be

used to energize the Tool Changing function for Toolholder release, but the valve must exhaust

ALL line pressure when unenergized. An electrically operated pneumatic valve is normally

used in an automated workcell. 3M highly recommends the installation of a Pressure Switch

in the Supply Line to the Servo Motor. This switch should not allow the unit to start if there is

any pressure in the Supply Line. Pressure in the line will cause internal components to come

into contact. This will either cause the motor not to spin, or cause very high internal forces,

eventually friction welding components together.

Air Regulator/Pressure Gauge

1/4" (6mm) Polyurethane

Tubing

Manual or Electrically

Operated Valve

5µm Filter

Shut off Valve

90 psi minimum

(6.2 Bar)

Dry, Non-lubricated

Air Supply

Pressure Switch

Quick

Exhaust

Printed Colors – Front:

Requester:

Marnie Cleveland

Creator:

deZinnia_25417

File Name:

Pneumatic Connections.ai

Structure #:

Illustration

Date:

04/24/19

This artwork has been created as requested by 3M. 3M is responsible for the artwork

AS APPROVED and assumes full responsibility for its correctness.

Scale:

1 Inch

Figure 7. Pneumatic Connections

The motors are provided with 1/4 inch and 6 mm diameter tubing push-lock fittings for

installation in the R 1/8 (Metric) Collet Unclamp Port located on the top of the Clamping

Housing (See Figure 8). Remove the shipping plug and install the desired size push-lock fitting.

If another type of fitting is desired, unscrew the existing fitting and replace it with any fitting

having an R 1/8 (Metric) thread. Be sure to use a thread seal product and do not overtighten

the fitting. The Unclamp Supply Line to the device should be 1/4 inch or 6 mm diameter flexible

polyurethane tubing. The tubing should be routed to the device such that there are no kinks

and that there is plenty of slack to allow for manipulator motion. Before inserting the tubing

into the air fitting, open the Shut-Off Valve to blow out any contaminants which may be in the

Unclamp Supply Line. The tubing can now be pushed into the self-locking fitting located on the

Clamping Housing as shown in Figure 8. Charge the Unclamp Supply Line with compressed

air and verify that there are no air leaks and that there is a minimum of 90 PSI (6.2 bar) at the

Servo Motor. If a minimum air pressure cannot be achieved, then an auxiliary air compressor or

booster pump must be installed. NOTE: 3M highly recommends the use of flexible polyurethane

ACT