Description of system and fundamentals of

operation

System operation description

The YORK Model YK Chiller is commonly applied to large air conditioning systems, but may be

used on other applications. The chiller consists of an open motor mounted to a compressor (with

integral speed increasing gears), condenser, evaporator and variable flow control.

The chiller is controlled by a modern state of the art Microcomputer Control Center that monitors

its operation. The Control Center is programmed by the operator to suit job specifications.

Automatic timed start-ups and shutdowns are also programmable to suit nighttime, weekends,

and holidays. The operating status, temperatures, pressures, and other information pertinent

to operation of the chiller are automatically displayed and read on a graphic display. Other

displays can be observed by pressing the keys as labeled on the Control Center. The chiller with

the OptiView Control Center is applied with an Electromechanical Starter, YORK Solid State Starter

(optional), or Variable Speed Drive (optional).

When the compressor motor is driven by a YORK Solid State Starter, one of two different starters

could be applied. Later production chillers are equipped with either the Style B Liquid Cooled Solid

State Starter (LCSSS) or the Medium Voltage Solid State Starter (MVSSS).

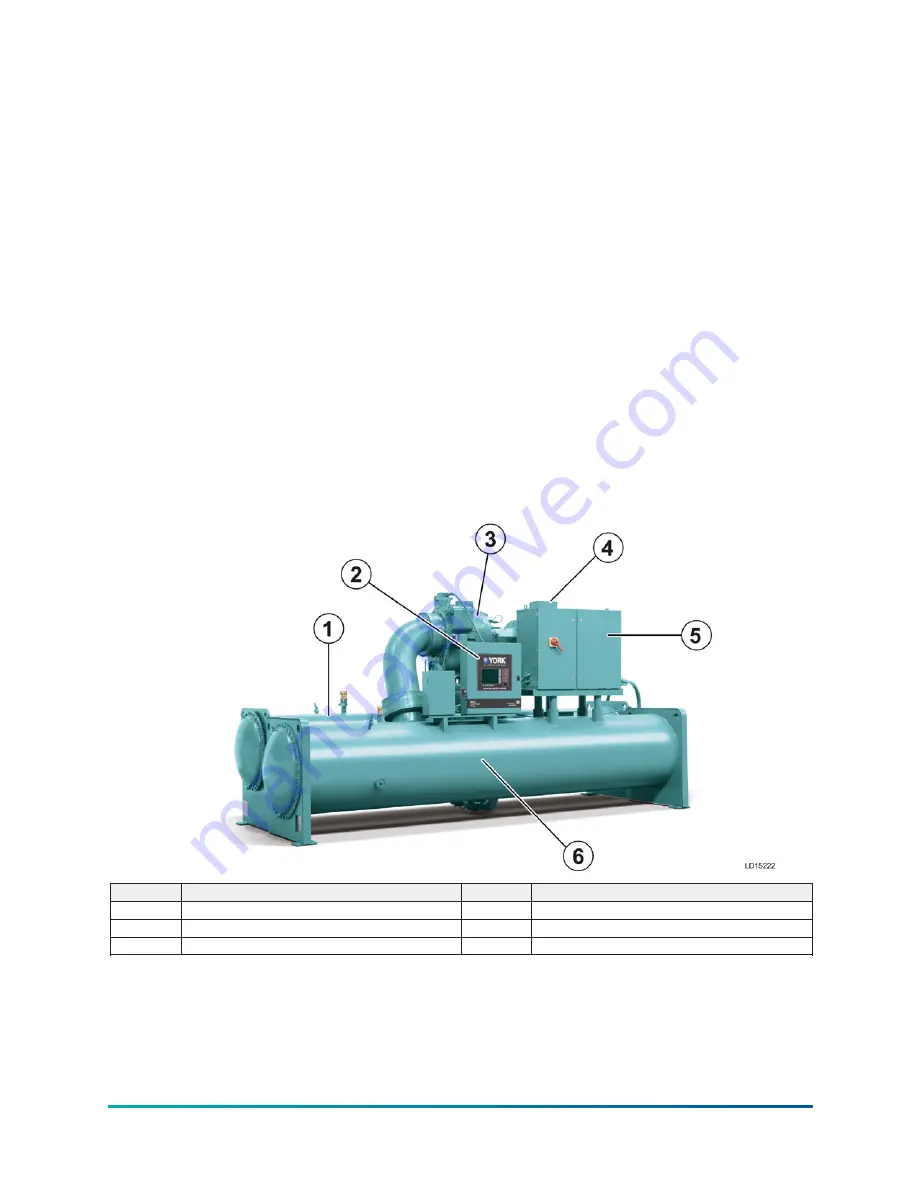

Figure 2: Model YK chiller

Callout

Description

Callout

Description

1

Condenser

2

Control center

3

Compressor

4

Motor

5

VSD

6

Evaporator

When the compressor motor is driven by a YORK Variable Speed Drive, there could be a Variable

Speed Drive (VSD) or a Medium Voltage Variable Speed Drive (MV VSD) applied.

In operation, a liquid (water or brine to be chilled) flows through the cooler, where boiling

refrigerant absorbs heat from the liquid. The chilled liquid is then piped to fan coil units or other air

Model YK Style H Centrifugal Liquid Chillers with OptiView Control Center

12