2. Inspection and Adjustment

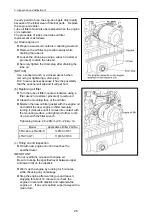

(3) Bleeding the fuel system

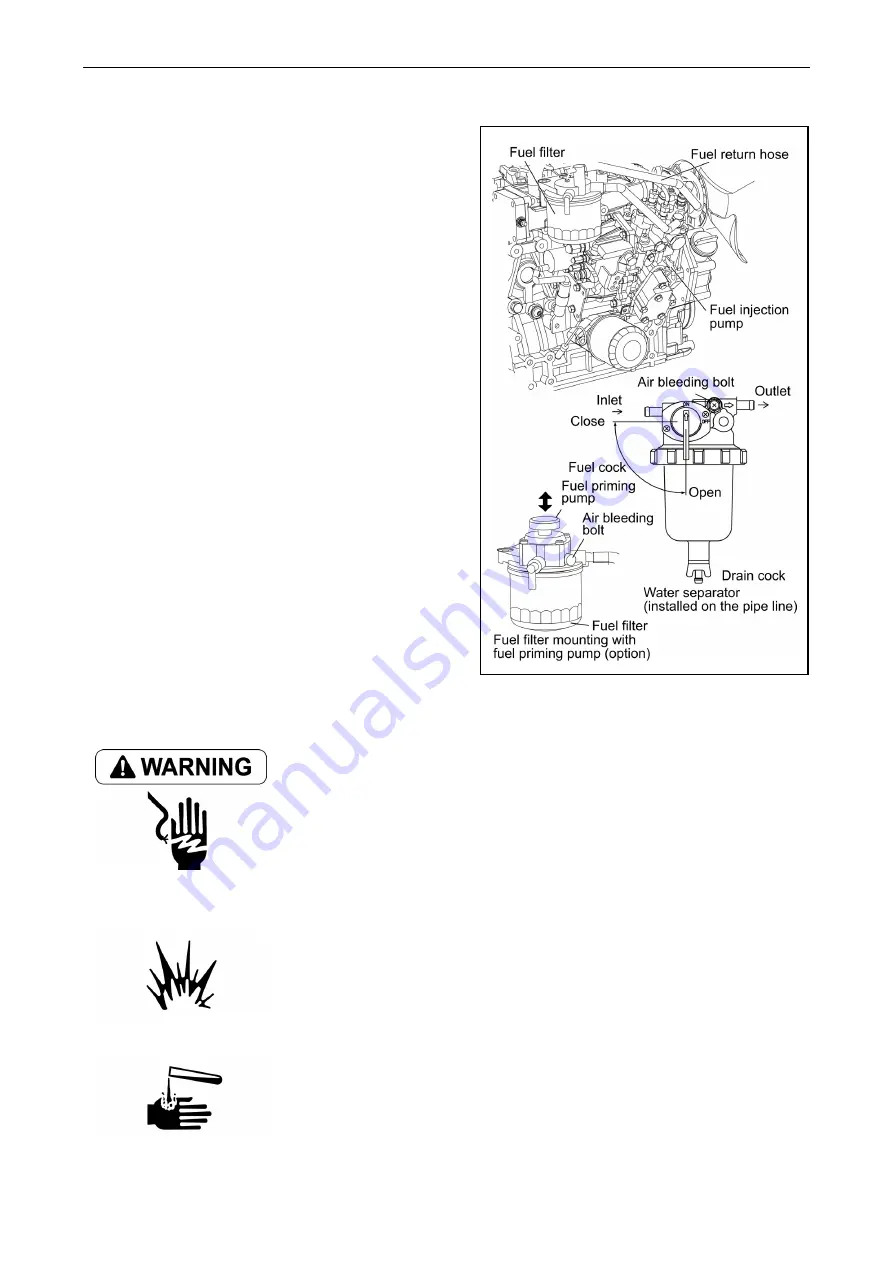

Bleed the fuel system according to the following

procedures. When there is air in the fuel system, the

fuel injection pump will not be able to function.

1) Check the fuel oil level in the fuel tank. Refuel if

insufficient.

2) Open the cock of the water separator.

3) Loosen the air bleeding bolt on the water

separator by turning 2~3 times to the

counter-clockwise using screw driver or spanner.

4) When the fuel coming out is clear and not mixed

with any bubble, tighten the air bleeding bolt.

5) Feed the fuel with the fuel priming pump or

electro-magnetic fuel feed pump.

In case of the engine using the electro-magnetic

fuel feed pump.

Turn the starter switch to the ON position and hold

it in the position for 10~15 seconds to operate the

fuel feed pump.

In case of the engine installed the fuel filter

mounting with the fuel priming pump.

The priming pump is on the top of the fuel filter

mounting. Move the priming pump up and down

to feed fuel until feel your hand slightly heavy.

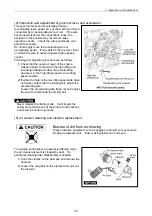

(4) Battery electrolyte level check and battery recharging

F

ire due to electric short-circuit

Make sure to turn off the battery switch or disconnect the negative

cable (-) before inspecting the electrical system. Failure to do so

could cause short-circuiting and fires.

Always disconnect the (-) Negative battery cable first before

disconnecting the battery cables from battery. An accidental "Short

circuit" may cause damage, fire and or personal injury.

And remember to connect the (-) Negative battery cable (back onto

the battery) LAST.

P

roper ventilation of the battery area

Keep the area around the battery well ventilated, paying attention to

keep away any fire source. During operation or charging, hydrogen

gas is generated from the battery and can be easily ignited.

D

o not come in contact with battery electrolyte

Pay sufficient attention to avoid your eyes or skin from being in contact

with the fluid. The battery electrolyte is dilute sulfuric acid and causes

burns. Wash it off immediately with a large amount of fresh water if

you get any on you.

29

Summary of Contents for 3TNV Series

Page 1: ...4TNV106 4TNV106T 4TNV94L 4TNV98 4TNV98T 3TNV82A 3TNV84 T 4TNV84 T 3TNV88 4TNV88 ...

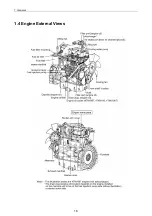

Page 31: ...1 General 1 4 Engine External Views 16 ...

Page 32: ...1 General 1 5 Structural Description 17 ...

Page 156: ...9 Starting Motor 9 1 2 Components 141 ...

Page 157: ...9 Starting Motor 9 1 3 Troubleshooting 142 ...

Page 172: ...9 Starting Motor 9 2 3 Troubleshooting 157 ...

Page 175: ...9 Starting Motor 2 Removal of magnetic switch Remove the M6 bolts 10mm 2 160 ...

Page 185: ...9 Starting Motor 3 Brush 1 Check wear of the brush and the brush spring force 170 ...

Page 194: ...10 Alternator 179 10 1 6 Troubleshooting ...

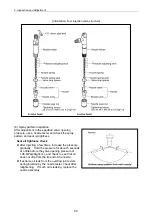

Page 195: ...11 Electric Wiring 180 11 ELECTRIC WIRING 11 1 Electric Wiring Diagram ...

Page 213: ......