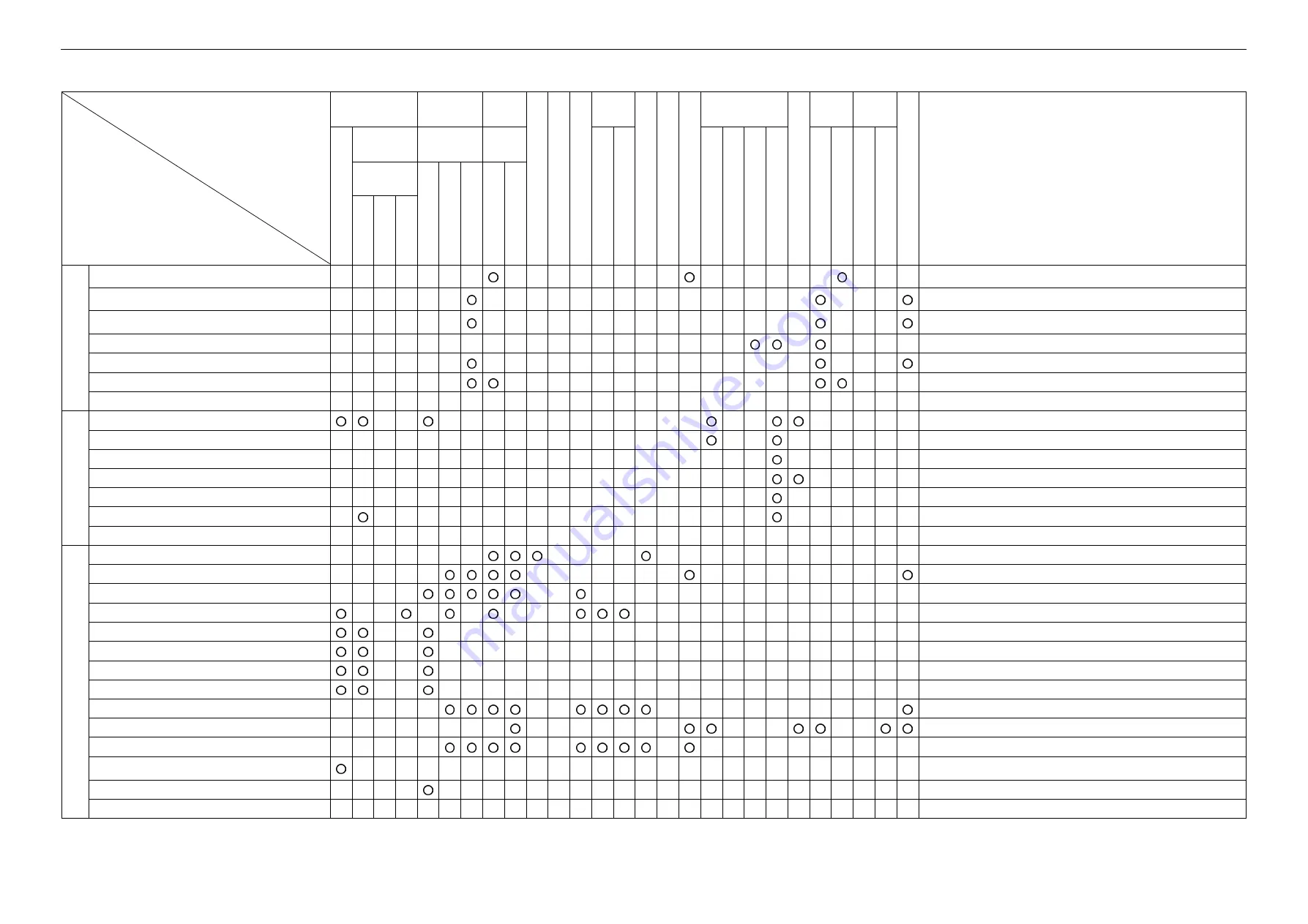

3. Troubleshooting

Starting failure

Insufficient

engine output

Poor

exhaust

color

Hunting

Lubricating oil

Cooling

water

Air

intake

Engine starts

but stops

soon.

Exhaust

color

During

work

Exhaust

smoke

Trouble symptom

Cause

Engi

ne do

es n

ot start.

None

Little

Much

Ordinary

Wh

ite

Black

Wh

ite

Black

High knocking sound during

combustion

Abnorm

al en

gi

ne sou

nd

Uneve

n comb

u

stion sou

nd

Durin

g idl

ing

Durin

g work

Larg

e eng

ine v

ibratio

n

Difficulty in ret

urnin

g to low s

pee

d

Excessive fue

l consum

ption

Excessive consumption

Diluti

on by fue

l oil

Mixture with w

ater

Low L.O. pressure

Much bl

ow-by

gas

Overheat

Low wat

er temperatur

e

Pressure dr

op

Pressure rise

Exhaust tempe

rature rise

Corrective action

Excessive cooling effect of radiator

Defective thermostat (kept closed) (See 2.2.7 in Chapter2.)

Insufficient cooling effect of radiator

Defective thermostat (kept opened)(See 2.2.7 in Chapter2.)

or slipping fan belt (See 2.2.2-2) in Chapter2.)

Insufficient coolant water

level

Check water leakage from cooling water system.

(See 2.2.1-4) in Chapter2.)

Cracked water jacket

Repair

or

replace.

Slackened

fan

belt

Adjust the belt tension. (See 2.2.2-2) in Chapter2.)

Defective

thermostat

Check or replace. (See 2.2.7 in Chapter2.)

Cool

ing W

ater

System

Improper properties of lubricating oil

Use

proper

lubricating

oil. (See 1.3.2 in Chapter1.)

Leakage

from

lubricating

oil

piping

system

r.

Repai

Insufficient

delivery

capacity

of

trochoid

pump

Check and repair. (See 5.5 in Chapter5.)

Clogged

lubricating

oil

filter

Clean

or

replace.

Defective pressure regulating valve

Clean,

adjust

or

replace.

Insufficient lubricating oil level

Add

proper

lubricating

oil. (See 2.2.1-3) in Chapter2.)

Lubric

atin

g System

Too early timing of fuel injection pump

Check

and

adjust.

(See

2.2.7-4)

in

Chapter2.)

Too late timing of fuel injection pump

Check and adjust. (See 2.2.7-4) in Chapter2.)

Improper properties of fuel oil

Use

proper

fuel

oil.

(See

1.3.1

in

Chapter1.)

Water entrance in fuel system

Perform

draining

from

the fuel filter. (See 2.2.3 and 2.2.5 in Chapter2.)

Clogged fuel filter

Clean

or

replace.

(See

2.2.5

in

Chapter2.)

Air entrance in fuel system

.)

Perform air bleeding. (See 2.2.3 in Chapter2

Clogged or cracked fuel pipe

e.

Clean or replac

Insufficient fuel supply to fuel injection pump

Check

the

fuel tank cock, fuel filter, fuel pipe, and fuel feed pump.

Uneven injection volume of fuel injection pump

Check and adjust.

Excessive

fuel

injection

volume

Check and adjust.

Poor spray pattern from fuel injection nozzle

Check

and

adjust.

(See

2.2.6

in

Chapter2.)

Priming failure

Foreign matter trapped in the valve inside the priming pump.

(Disassemble and clean.)

Clogged strainer at feed pump inlet

r.

Clean the straine

Fuel system

55

Summary of Contents for 3TNV Series

Page 1: ...4TNV106 4TNV106T 4TNV94L 4TNV98 4TNV98T 3TNV82A 3TNV84 T 4TNV84 T 3TNV88 4TNV88 ...

Page 31: ...1 General 1 4 Engine External Views 16 ...

Page 32: ...1 General 1 5 Structural Description 17 ...

Page 156: ...9 Starting Motor 9 1 2 Components 141 ...

Page 157: ...9 Starting Motor 9 1 3 Troubleshooting 142 ...

Page 172: ...9 Starting Motor 9 2 3 Troubleshooting 157 ...

Page 175: ...9 Starting Motor 2 Removal of magnetic switch Remove the M6 bolts 10mm 2 160 ...

Page 185: ...9 Starting Motor 3 Brush 1 Check wear of the brush and the brush spring force 170 ...

Page 194: ...10 Alternator 179 10 1 6 Troubleshooting ...

Page 195: ...11 Electric Wiring 180 11 ELECTRIC WIRING 11 1 Electric Wiring Diagram ...

Page 213: ......