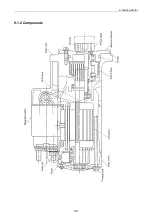

8. Turbochager

8.8 Troubleshooting

Sufficient turbocharger performance and required engine output cannot be obtained if there is any fault.

In such a case, first check each engine part to see there is no engine fault. Then inspect the

turbocharger for troubleshooting according to the procedure shown below.

8.8.1 Excessively exhaust smoke

(1) Insufficient intake air volume

Cause Corrective

action

1) Clogged air cleaner element

2) Blocked air intake port

3) Leak from a joint in intake line

Replace or wash the element.

Correct to the normal state.

Inspect and repair.

(2) Turbocharger revolution failure

Cause Corrective

action

1) Deposit of impurities in oil sticking on the turbine

side seal portion to make turbine revolution heavy

2) Sticking bearing

Insufficient lubrication or clogged lubrication piping

Excessively high oil temperature

Unbalanced rotating part

Insufficient warming up or sudden stoop from

loaded operation (no-load operation)

3) Contact or breakdown of turbine wheel or blower

vane

Excessive revolution

Excessive exhaust temperature rise

Foreign matter invasion

worn bearing

Assembly defect

Turbocharger overhaul (disassembly and

washing) with lubricating oil replacement

Turbocharger overhaul (disassembly and repair)

Lubricating oil line inspection, repair of defective

portion and lubricating oil replacement

Rotating part replacement or washing

Strict observance of instructions in operation

manual

Inspection and repair of each engine part

Perfect foreign matter elimination in disassembled

state, followed by inspection and repair of

individual air cleaner and engine components

turbocharger overhaul (disassembly and repair)

Reassembly

(3) Influence of exhaust resistance

Cause Corrective

action

1) Exhaust gas leak before the turbocharger to

decrease its revolutions

2) Deformed or clogged exhaust pipe to decrease

turbocharger revolutions

Joint inspection and correction

Correct to the normal state.

8.8.2 White smoke generation

Cause Corrective

action

1) Clogged or deformed oil return pipe causing oil

flow to the blower or turbine side

2) Excessive bearing wear causing abnormal wear or

damage of seal ring

Repair or pipe replacement

Turbocharger disassembly and repair

138

Summary of Contents for 3TNV Series

Page 1: ...4TNV106 4TNV106T 4TNV94L 4TNV98 4TNV98T 3TNV82A 3TNV84 T 4TNV84 T 3TNV88 4TNV88 ...

Page 31: ...1 General 1 4 Engine External Views 16 ...

Page 32: ...1 General 1 5 Structural Description 17 ...

Page 156: ...9 Starting Motor 9 1 2 Components 141 ...

Page 157: ...9 Starting Motor 9 1 3 Troubleshooting 142 ...

Page 172: ...9 Starting Motor 9 2 3 Troubleshooting 157 ...

Page 175: ...9 Starting Motor 2 Removal of magnetic switch Remove the M6 bolts 10mm 2 160 ...

Page 185: ...9 Starting Motor 3 Brush 1 Check wear of the brush and the brush spring force 170 ...

Page 194: ...10 Alternator 179 10 1 6 Troubleshooting ...

Page 195: ...11 Electric Wiring 180 11 ELECTRIC WIRING 11 1 Electric Wiring Diagram ...

Page 213: ......