1. General

21

(4) Perform maintenance without fail.

Note

:

Inspections to be carried out by the user and by the maker are divided and set down in the “List

of Periodic Inspections” and should be checked carefully.

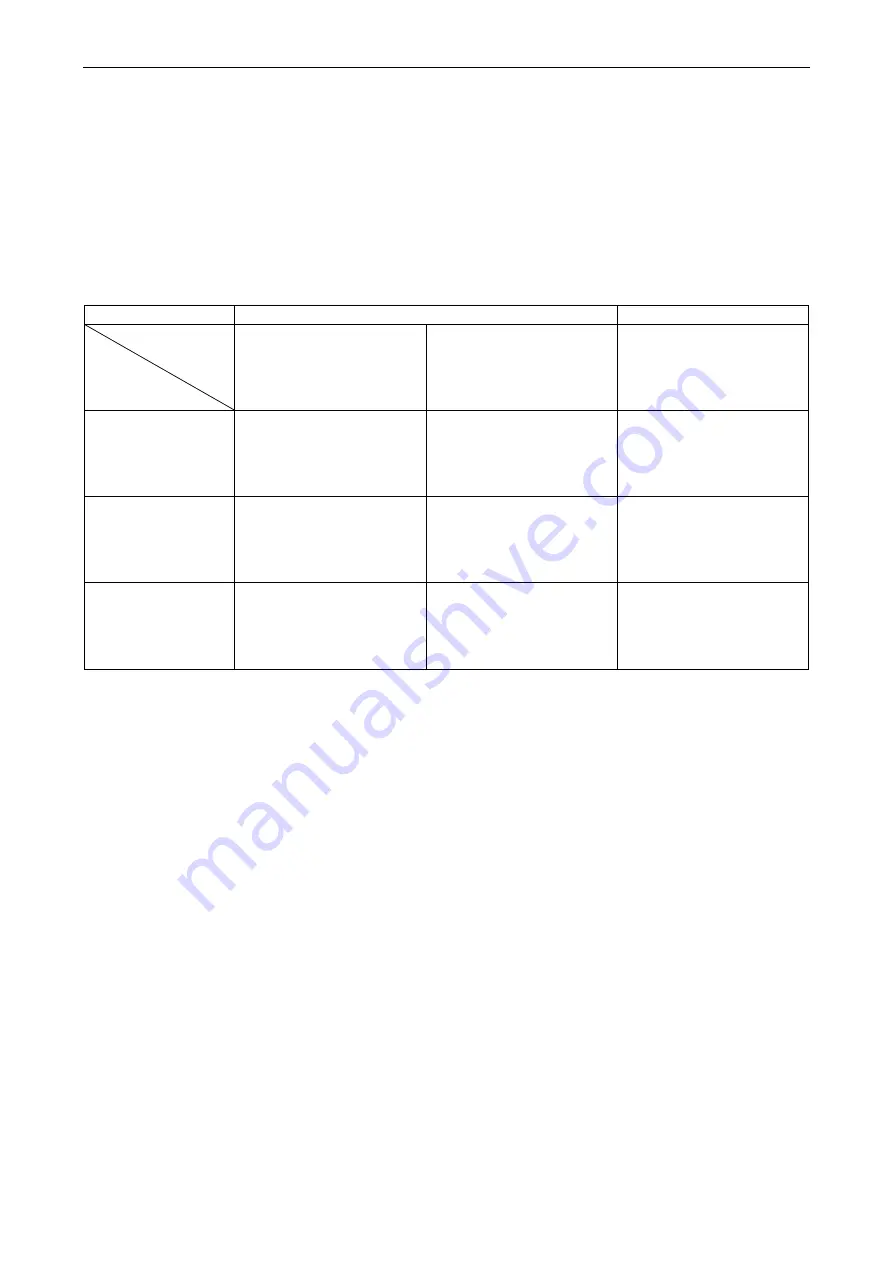

(5) Maintenance period and Quality guarantee period for exhaust emission related parts

The maintenance of the parts related to the exhaust emission must be carried out in the maintenance

period as shown in the below table.

A guarantee period is that either the operation hours or years shown in the table come first in the

condition that the maintenance inspection was carried out based on the “List of Periodic Inspections”.

Maintenance period

Quality Guarantee Period

Parts

Power Rating

Fuel nozzle cleaning

Adjustment, cleaning,

repairs for fuel nozzle, fuel

pump, turbocharger,

electronic control unit etc.

For nozzle, fuel pump,

turbocharger

37 <= kW < 130

Every 1500 hours

(applied from Tier 2)

Every 3000 hours

(applied from Tier 2)

3000 hours / 5 years

19 <= kW < 37

except constant

speed engines >=

3000min

-1

Every 1500 hours

Every 3000 hours

3000 hours / 5 years

KW < 19

And constant speed

engines beyond

3000min under

37kW

-1

Every 1500 hours

Every 3000 hours

1500 hours / 2 years

Summary of Contents for 3TNV Series

Page 1: ...4TNV106 4TNV106T 4TNV94L 4TNV98 4TNV98T 3TNV82A 3TNV84 T 4TNV84 T 3TNV88 4TNV88 ...

Page 31: ...1 General 1 4 Engine External Views 16 ...

Page 32: ...1 General 1 5 Structural Description 17 ...

Page 156: ...9 Starting Motor 9 1 2 Components 141 ...

Page 157: ...9 Starting Motor 9 1 3 Troubleshooting 142 ...

Page 172: ...9 Starting Motor 9 2 3 Troubleshooting 157 ...

Page 175: ...9 Starting Motor 2 Removal of magnetic switch Remove the M6 bolts 10mm 2 160 ...

Page 185: ...9 Starting Motor 3 Brush 1 Check wear of the brush and the brush spring force 170 ...

Page 194: ...10 Alternator 179 10 1 6 Troubleshooting ...

Page 195: ...11 Electric Wiring 180 11 ELECTRIC WIRING 11 1 Electric Wiring Diagram ...

Page 213: ......