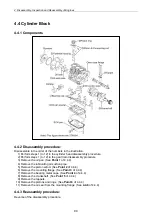

4. Disassembly, Inspection and Reassembly of Engines

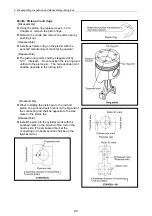

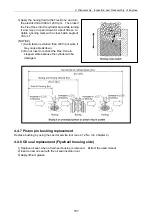

[Reassemble]

Apply sealant (code No.977770-01212) and install

the mounting flange by matching the two dowel

pins. After assembly, raise the engine with its

mounting flange on the bottom side.

Unforeseen injury may arise due to falling of slipping

when raising or reversing the engine. Carefully

operate so as not to lose balance.

Point4: Journal bearing cap

[Disassemble]

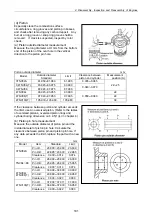

4TNV106(T) 36.250 36.275

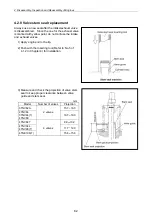

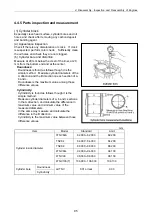

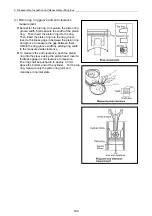

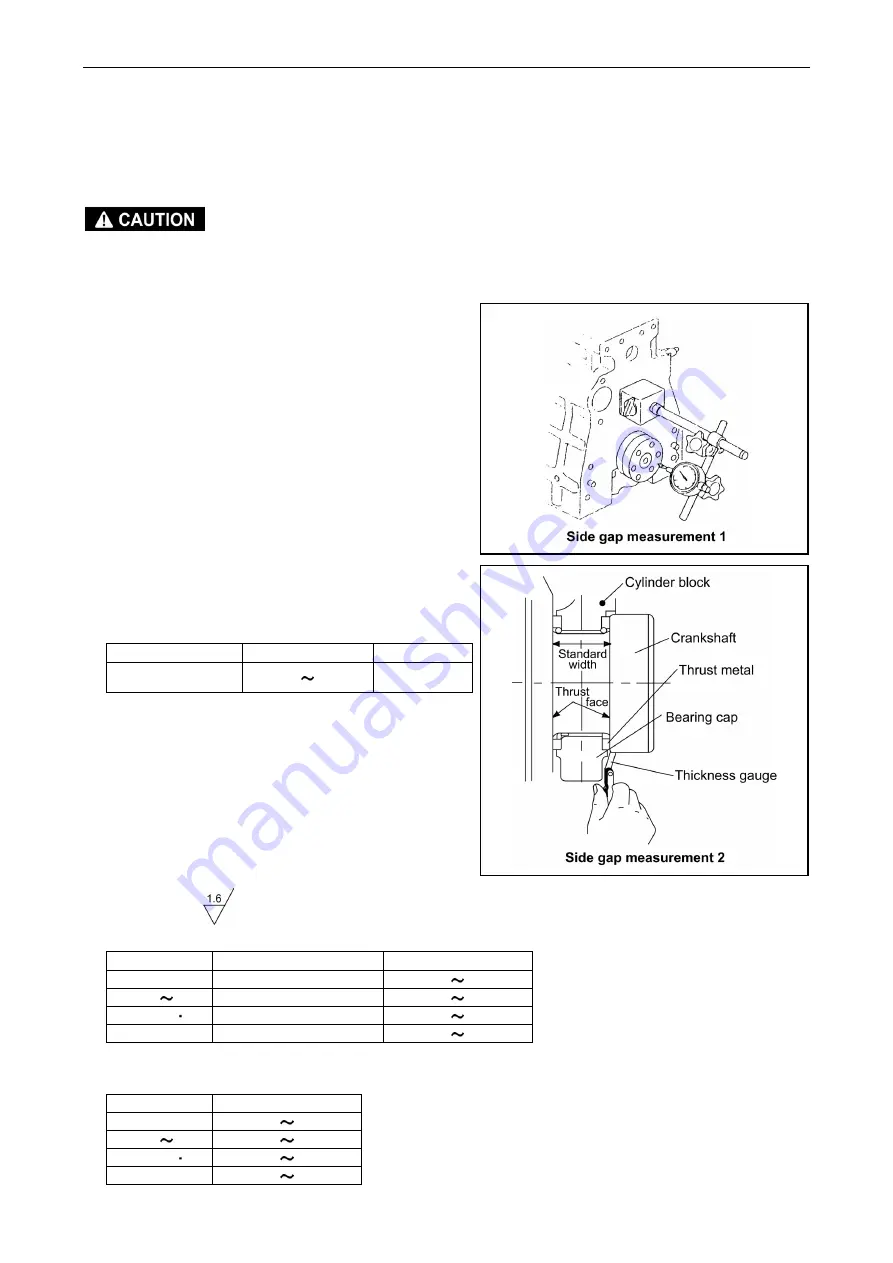

Before removing the journal bearing, measure the

crankshaft side gap. Measure it in either method

because there are the next two methods.

1) Install a dial gage on the cylinder block, and

move a crankshaft in front and back, and

measure the side gap as shown in the right

figure.

2) Put a thickness gauge in the clearance between

thrust metal and crankshaft directly, and measure

it.

Side gap standard mm

Model Standard

Limit

All models

0.13 0.23

The standard width of the crankshaft thrust part

mm

Model Standard

thickness

3TNV82A 25.250 25.271

TNV84 88 28.250 28.271

0.28

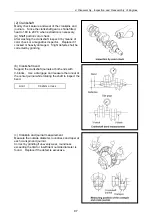

[Reassemble]

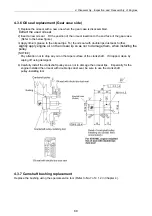

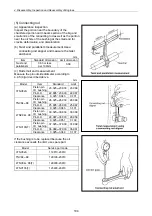

If the side gap exceeds the standard, replace the

thrust metal with an oversize one.

Machine the standard width of the crankshaft

thrust part into the dimension of the below table at

the same time.

Refer to a parts catalog when ordering the part.

The surface finishing precision (refer to 4.4.5(2) in

Chapter4):

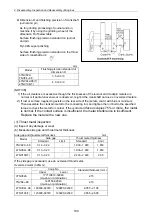

0.25mm Oversized thrust metal (0.25DS) mm

0.25DS

Thrust metal assy code

Standard thickness

3TNV82A 119810-02940 2.055 2.105

TNV84 88 129150-02940 2.055 2.105

4TNV94L 98 129900-02940

2.055 2.105

4TNV106(T) 123900-02940 2.555 2.605

32.250 32.275

4TNV94L 98

92

Summary of Contents for 3TNV Series

Page 1: ...4TNV106 4TNV106T 4TNV94L 4TNV98 4TNV98T 3TNV82A 3TNV84 T 4TNV84 T 3TNV88 4TNV88 ...

Page 31: ...1 General 1 4 Engine External Views 16 ...

Page 32: ...1 General 1 5 Structural Description 17 ...

Page 156: ...9 Starting Motor 9 1 2 Components 141 ...

Page 157: ...9 Starting Motor 9 1 3 Troubleshooting 142 ...

Page 172: ...9 Starting Motor 9 2 3 Troubleshooting 157 ...

Page 175: ...9 Starting Motor 2 Removal of magnetic switch Remove the M6 bolts 10mm 2 160 ...

Page 185: ...9 Starting Motor 3 Brush 1 Check wear of the brush and the brush spring force 170 ...

Page 194: ...10 Alternator 179 10 1 6 Troubleshooting ...

Page 195: ...11 Electric Wiring 180 11 ELECTRIC WIRING 11 1 Electric Wiring Diagram ...

Page 213: ......