9. Starting Motor

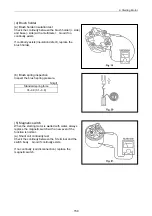

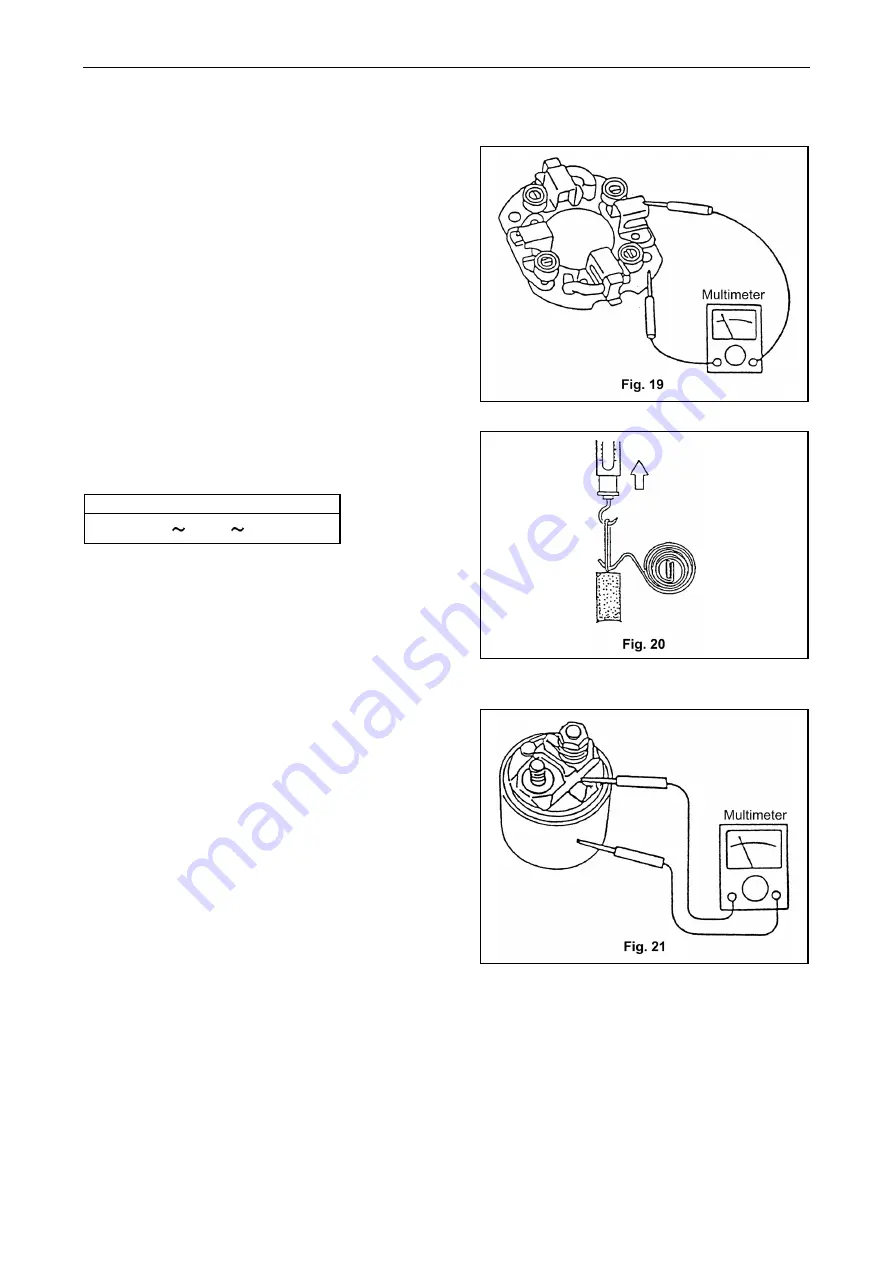

(4) Brush holder

(a) Brush holder insulation test

Check the continuity between the brush holder (+ side)

and base (- side) with a multimeter. Good if no

continuity exists.

If continuity exists (insulation defect), replace the

brush holder.

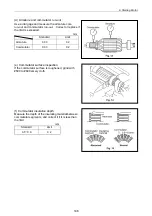

(b) Brush spring inspection

Inspect the brush spring pressure.

N(kgf)

Standard spring force

31 39 (3.1 3.9)

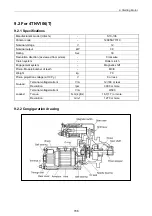

(5) Magnetic switch

When the starting motor is wetted with water, always

replace the magnetic switch with a new even if the

function is normal.

(a) Shunt coil continuity test

Check the continuity between the S terminal and the

switch body. Good if continuity exists.

If no continuity (coil disconnection), replace the

magnetic switch.

150

Summary of Contents for 3TNV Series

Page 1: ...4TNV106 4TNV106T 4TNV94L 4TNV98 4TNV98T 3TNV82A 3TNV84 T 4TNV84 T 3TNV88 4TNV88 ...

Page 31: ...1 General 1 4 Engine External Views 16 ...

Page 32: ...1 General 1 5 Structural Description 17 ...

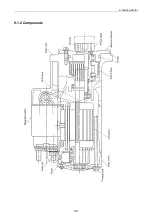

Page 156: ...9 Starting Motor 9 1 2 Components 141 ...

Page 157: ...9 Starting Motor 9 1 3 Troubleshooting 142 ...

Page 172: ...9 Starting Motor 9 2 3 Troubleshooting 157 ...

Page 175: ...9 Starting Motor 2 Removal of magnetic switch Remove the M6 bolts 10mm 2 160 ...

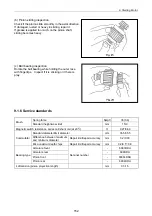

Page 185: ...9 Starting Motor 3 Brush 1 Check wear of the brush and the brush spring force 170 ...

Page 194: ...10 Alternator 179 10 1 6 Troubleshooting ...

Page 195: ...11 Electric Wiring 180 11 ELECTRIC WIRING 11 1 Electric Wiring Diagram ...

Page 213: ......