4 - 98

ENG

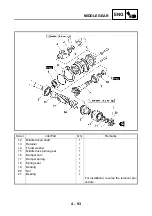

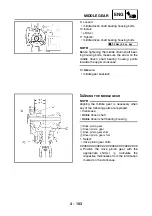

MIDDLE GEAR

2. Tighten:

• middle driven shaft nut

While holding the universal joint driven yoke

with the universal joint holder, tighten the

middle driven shaft nut.

CAUTION:

@

Tighten the middle driven shaft nut in small

increments, checking the torque it takes to

keep the middle driven gear turning in the

middle driven shaft bearing housing - not

the torque it takes to start it turning.

@

Universal joint holder

90890-04062

T

R

.

.

90 Nm (9.0 m · kg)

3. Measure:

• middle driven gear spinning torque

(with the beam-type torque wrench)

Under specification

→

Repeat steps (2) and

(3).

CAUTION:

@

• Never exceed the standard spinning

torque.

• If the spinning torque is not high enough,

tighten the middle driven shaft nut

slightly and check the spinning torque

again. Repeat these steps until the proper

spinning torque is obtained.

• If the spinning torque specification is

exceeded, remove the middle driven shaft

assembly, install a new collapsible collar,

and repeat steps (1) ~ (3).

@

T

R

.

.

Middle driven gear spinning

torque

0.4 ~ 0.5 Nm (0.04 ~ 0.05 m • kg)

Summary of Contents for VMX12 2001

Page 1: ...VMX12 2001 3LRD AE1 SERVICEMANUAL ...

Page 2: ......

Page 8: ......

Page 9: ...GEN INFO 1 ...

Page 11: ...GEN INFO ...

Page 21: ......

Page 22: ...SPEC 2 ...

Page 24: ...SPEC ...

Page 52: ...2 28 SPEC OIL FLOW DIAGRAMS 1 Camshaft 2 Main gallery 3 Crankshaft 4 Oil level switch ...

Page 54: ...2 30 SPEC OIL FLOW DIAGRAMS 1 Crankshaft 2 Oil pipe 3 Oil filter ...

Page 65: ...CHK ADJ 3 ...

Page 125: ......

Page 126: ...ENG 4 ...

Page 130: ...ENG ...

Page 236: ......

Page 237: ...COOL 5 ...

Page 239: ...COOL ...

Page 258: ...CARB 6 ...

Page 260: ...CARB ...

Page 272: ......

Page 273: ...CHAS 7 ...

Page 389: ......

Page 390: ...ELEC 8 ...

Page 396: ...8 4 ELEC SWITCHES ...

Page 417: ...8 25 ELEC STARTER MOTOR 3 Install O rings 1 bolts 2 New T R 5 Nm 0 5 m kg ...

Page 445: ...TRBL SHTG 9 ...