1 - 3

GEN

INFO

EAS00023

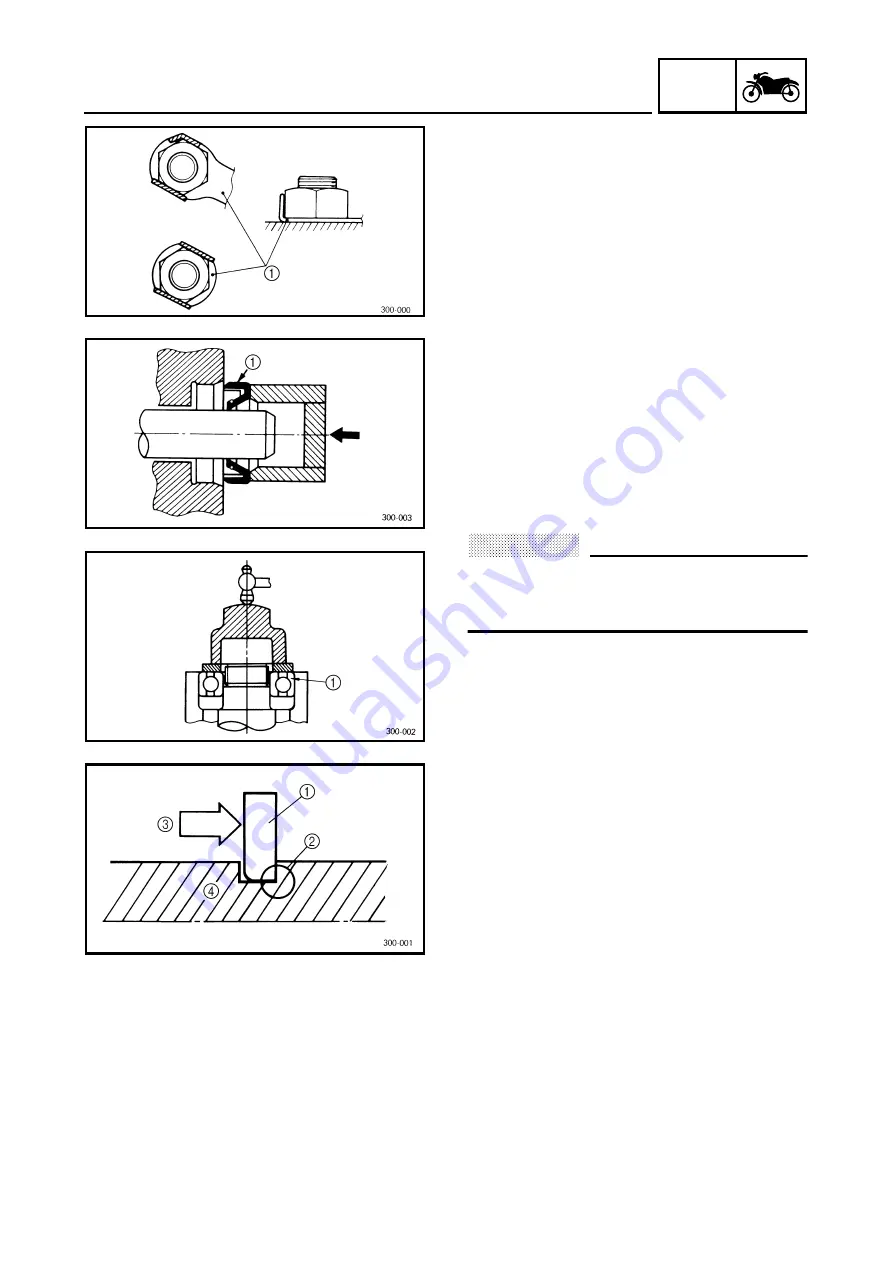

LOCK WASHERS/PLATES AND COTTER

PINS

After removal, replace all lock washers/plates

1

and cotter pins. After the bolt or nut has

been tightened to specification, bend the lock

tabs along a flat of the bolt or nut.

EAS00024

BEARINGS AND OIL SEALS

Install bearings and oil seals so that the manu-

facturer’s marks or numbers are visible. When

installing oil seals, lubricate the oil seal lips

with a light coat of lithium soap base grease.

Oil bearings liberally when installing, if appro-

priate.

1

Oil seal

CAUTION:

@

Do not spin the bearing with compressed

air because this will damage the bearing

surfaces.

@

1

Bearing

EAS00025

CIRCLIPS

Before reassembly, check all circlips carefully

and replace damaged or distorted circlips.

Always replace piston pin clips after one use.

When installing a circlip

1

, make sure the

sharp-edged corner

2

is positioned opposite

the thrust

3

that the circlip receives.

4

Shaft

IMPORTANT INFORMATION

Summary of Contents for VMX12 2001

Page 1: ...VMX12 2001 3LRD AE1 SERVICEMANUAL ...

Page 2: ......

Page 8: ......

Page 9: ...GEN INFO 1 ...

Page 11: ...GEN INFO ...

Page 21: ......

Page 22: ...SPEC 2 ...

Page 24: ...SPEC ...

Page 52: ...2 28 SPEC OIL FLOW DIAGRAMS 1 Camshaft 2 Main gallery 3 Crankshaft 4 Oil level switch ...

Page 54: ...2 30 SPEC OIL FLOW DIAGRAMS 1 Crankshaft 2 Oil pipe 3 Oil filter ...

Page 65: ...CHK ADJ 3 ...

Page 125: ......

Page 126: ...ENG 4 ...

Page 130: ...ENG ...

Page 236: ......

Page 237: ...COOL 5 ...

Page 239: ...COOL ...

Page 258: ...CARB 6 ...

Page 260: ...CARB ...

Page 272: ......

Page 273: ...CHAS 7 ...

Page 389: ......

Page 390: ...ELEC 8 ...

Page 396: ...8 4 ELEC SWITCHES ...

Page 417: ...8 25 ELEC STARTER MOTOR 3 Install O rings 1 bolts 2 New T R 5 Nm 0 5 m kg ...

Page 445: ...TRBL SHTG 9 ...