4 - 14

Watkiss Automatic SpineMaster Service Manual - Edited 17/06/04

Service Procedures

•

Machine Adjustments

4.7.6 Setting the Solenoid

Procedure

1. Loosen the Solenoid mounting screws slightly. You should be able to

move the Solenoid, but the screws should be just tight enough to allow the

Solenoid to stay in position.

2. Loosen the Eccentric Cam.

3. Fully depress the Plunger (see Figure 4:22) and adjust the position of the

Solenoid to give an air gap of 2.0mm between the tip of the Actuator Pawl

and the tip of the Stop on the Control Collar.

4. Rotate the Eccentric Cam until the airgap is limited to 1.5mm. Tighten the

Eccentric Cam.

5. Tighten the Solenoid mounting screws, and recheck the airgap.

4.7.7 Adjusting the Stop

If booklet spines are being formed unevenly, it is possible that the Stop needs

adjusting. It is essential that the Stop is parallel with the Clamp, and that the

minimum depth is correctly set.

Procedure

1. Switch off the power and disconnect the mains input.

2. Remove the Side Covers.

3. Rotate the Adjuster Shaft (265-835) anti-clockwise, to bring the Stop to its

minimum depth. Use a 13mm spanner to loosen the Trantorque Bush on

the end of the Adjuster Shaft.

PARTS REQUIRED

TOOLS REQUIRED

None

4mm Allen Key

952-382 Feeler Gauges, Metric

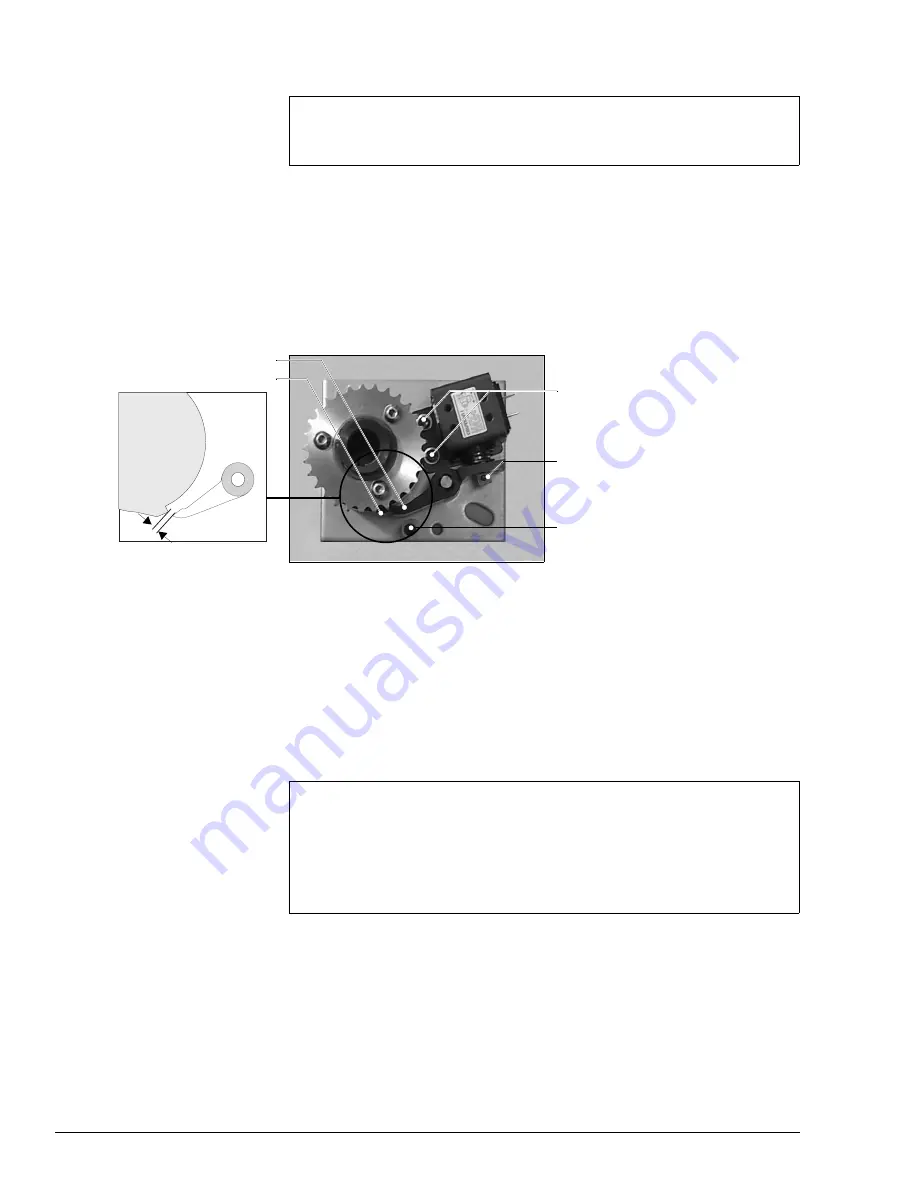

Figure 4:22 Solenoid Adjustment

Solenoid Mounting screws

Plunger

Eccentric Cam

Actuator Pawl

2mm Airgap (once set, this

should be limited to 1.5mm

by the Eccentric Cam.

Stop

PARTS REQUIRED

TOOLS REQUIRED

Locktite 242

3mm Allen Key

4mm Allen Key

8mm Spanner

13mm Spanner

952-421 0.5mm Feeler Gauge