Operating manual Universal Control Unit for Powder Spray Guns EPG-SPRINT XE

10 Inspections in Accordance with DIN EN 50177: 2009

60

Order number 2354913 | Edition 10/2022

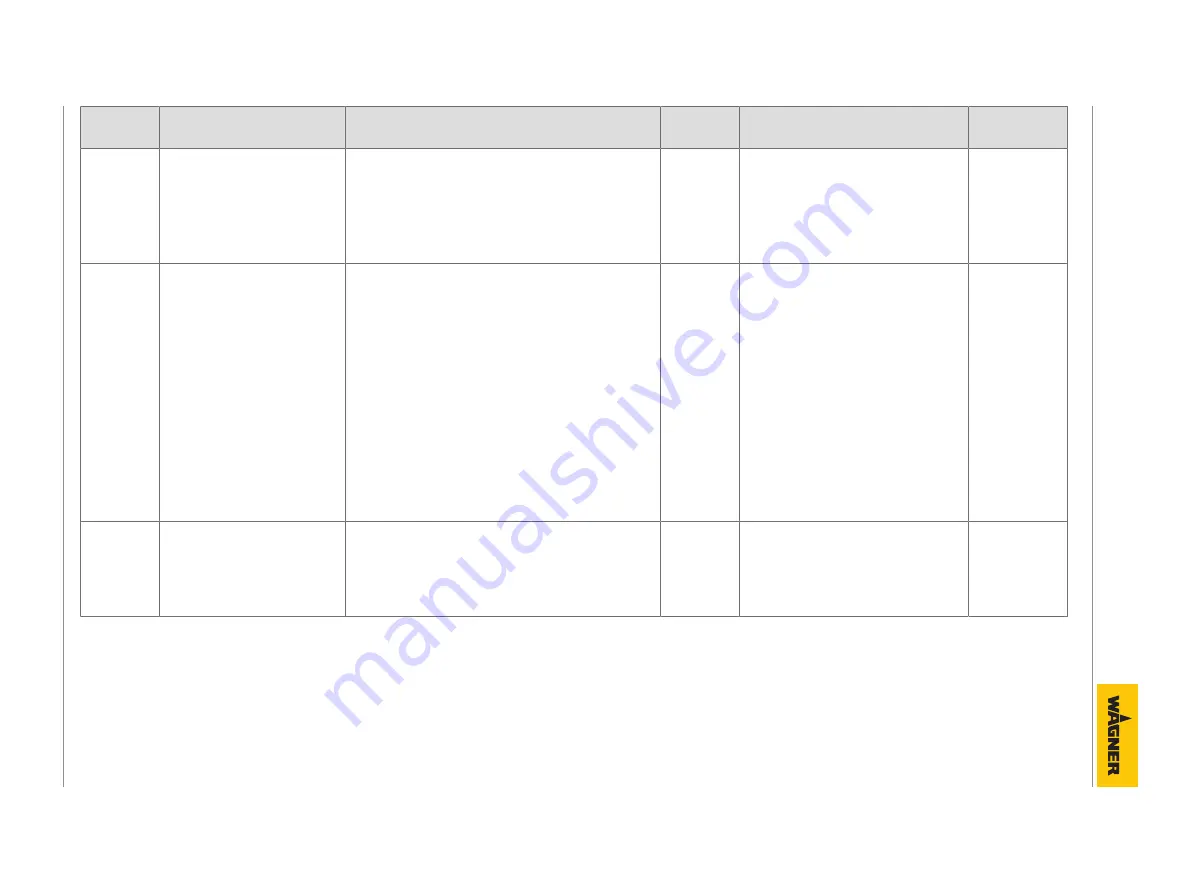

Section

Type of inspection

Requirements

Inspection

by

Type of inspection

Inspection in-

terval

6

Ground leaking resistance

from the work piece attach-

ment point

The ground leaking resistance of the attachment

point of every work piece may be 1 megohm at

most (measuring voltage must be 500 V or

1000 V). The design of the work piece holder

must ensure that the work pieces remain

grounded during coating.

SP

ME/CM

Measure the ground leaking resis-

tance (ground potential of the

workpiece mount)

maximum 1 MOhm @ 500 V/1000

V.

Weekly

7

Measures to take if the work

pieces are insufficiently

grounded

If sufficient work piece grounding in accordance

with section 6 cannot be ensured, appropriate

equipment, e.g., ionizers, must be used to dis-

charge electric charges on the work piece. Such

equipment must not exceed the permitted dis-

charge energy of the spraying systems with

which it is used. In terms of permitted discharge

energy, this equipment must be put through the

same inspections as the powder spraying sys-

tems used with it. The discharge equipment

must be interlocked with the spraying system

such that the high voltage is switched off and

that coating cannot take place if the discharge

equipment malfunctions.

SP

ME/FT/CI

Measurement of discharge energy,

check the monitoring equipment's

test function by triggering it.

Weekly

8

Effectiveness of the manu-

ally or automatically actu-

ated fire extinguishing sys-

tems (room protection sys-

tem)

Effectiveness of the manually or automatically

actuated fire extinguishing systems (room pro-

tection system).

MFR/FPE

FT

Trigger fire extinguishing system,

observe manufacturer's require-

ments.

6 months