45

B.

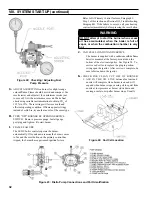

OIL PRIMARy CONTROL

(Oil Primary)

1. Burner (Oil Primary) will not come on.

a. No power to Oil Primary.

b. Oil Primary is in lockout or restricted mode.

Press reset button for one (1) second to exit

lockout. If control has recycled three times

within the same call for heat, it will enter into

restricted mode. To reset from restricted mode,

refer to Section VIII, Paragraph I, Step 2 for

details.

c. CAD cell seeing light.

d. CAD assembly defective.

e. Control motor relay is stuck closed (see note

below).

2. Burner (control) will light, then shut down after a

short time, then restart after one (1) minute.

a. CAD cell is defective.

b. Air leaking into oil line causing flame out.

c. Defective nozzle causing flame to be erratic.

d. Excessive airflow or draft causing flame to leave

burner head.

e. Excessive back pressure causing flame to be

erratic.

3. Control locks out after Trial For Ignition (TFI).

a. No oil to burner.

b. Shorted electrodes.

c. Nozzle clogged.

d. Airflow too high.

e. Ignitor module defective.

XII. TROUBLESHOOTING (continued)

f. CAD cell defective.

g. Oil valve stuck open or closed.

Note

: The Safety Monitoring Circuit (SMC) is

designed to provide lockout in the event of a

stuck or welded motor relay.

NOTICE

If flame is not established within 15 seconds of

oil valve actuation (known as Trial For Ignition

[TFI]) lockout will occur. Lockout is indicated

by a red LED solid-on located on the oil primary

control.

Hard Lockout will occur if the Oil Primary

Control locks-out three (3) times during a call

for heat. This is indicated by red light reset

button solid-on.

C.

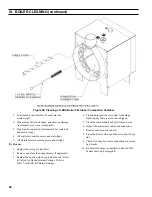

INTELLIGENT OIL BOILER CONTROL

• Cold Start Boiler Control

is used on Boilers without

Tankless Heaters.

1. When a problem occurs with the boiler operation,

the Boiler Control easily provides specific, valuable

information to help resolve the issue quickly. The

display on the Boiler Control should be the first

place to check.

a. If an Error Code “

Err

”

IS NOT

displayed on the

Boiler Control: In this circumstance, Table 13

can be used to determine the problem and

possible causes.

System Condition

Diagnostic Condition

Check

Action

Boiler is cold, house is

cold.

Display is OFF.

120 Vac System power.

Turn system power on.

Display is ON.

24 Vac T-T

No 24 V; replace control.

24 V present; disconnect

thermostat, short T-T.

Boiler starts, check wiring and thermostat.

120 Vac at B1-B2

• If no, replace control.

• If yes, check burner and wiring.

Refer to

Err

on display.

-----

Boiler is hot, house is

cold.

Display is ON.

120 Vac at C1-C2

• 120 Vac at C1-C2, check wiring to

pump.

• Wiring OK, is pump running?

• If not, replace the pump.

• If pump is running, check for trapped air

or closed zone valves

TABLE 13: TROUBLESHOOTING GUIDE

Summary of Contents for LE DV Series

Page 5: ...5 I General Information Figure 1A LEDV Packaged Water Boiler with Beckett AFII Burner ...

Page 6: ...6 I General Information continued Figure 1B LEDV Packaged Water Boiler with Riello BF Burner ...

Page 19: ...19 v venting continued Figure 11 Vent Installation Figure 12 Vent Connector Un Assembled ...

Page 20: ...20 v venting continued Figure 13 Vent Connector Assembled Figure 14 Air Intake Installation ...

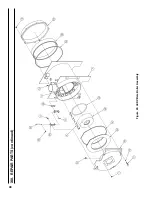

Page 48: ...48 xiii Repair Parts continued Figure 29 LEDV Bare Boiler Assembly ...

Page 50: ...50 xiii Repair Parts continued Figure 30 LEDV Boiler Jacket Insulation ...

Page 55: ...55 xiii Repair Parts continued Figure 33 Vent Kit Repair Parts ...

Page 60: ...60 U S Boiler Company Inc P O Box 3020 Lancaster PA 17604 1 888 432 8887 www usboiler net ...