36

IX. OPERATING (continued)

Press and release the

“

I

”

key on the Boiler Control

to change from one parameter to the next. Each

setting will alternately flash between the relevant

display code and its corresponding value.

Operating Mode Options

t

Status Numbers:

Standby

Running

Self Test)

bt

Boiler Temperature

P

Operating Setpoint (Outdoor Reset)

HL

High Limit Setting

HdF

High Limit Differential

hr

Heat Request Status

dh

DHW Request Status

Err

Boiler Error

For example, when the “

I

” key is pressed on the

Boiler Control until “

bt

” is displayed, it will then

flash a three digit number (such as “

0

”) followed

by either “

F

” (or “

C

”). This indicates that the boiler

water temperature is

180°F. Other operating

parameters display the information in a similar

fashion.

Please note that in operating mode to hold the

display on the value the user can press and hold

either the Up

ñ

or Down

ò

keys and the value will

be continuously shown. This may be helpful in

watching a value “live”.

4.

Changing the Adjustable Parameters

To adjust parameters such as the High Limit

Setpoint and High Limit Differential:

a. Using the Boiler Control display, access the

adjustment mode by pressing and holding the Up

ñ

, Down

ò

, and “

I

” keys simultaneously for

three (3) seconds. This procedure is intended to

discourage unauthorized changes or accidental

changes to limit settings.

b. Press the “

I

” key to display available Adjust-

ment Mode options. Select an option.

c. Press the Up

ñ

and Down

ò

keys to adjust the

displayed setpoint to the desired value.

d. To return to the normal operating mode from the

Adjustment Mode, when the “

bc

” option is

displayed, press either the Up

ñ

or Down

ò

key.

If no keys are pressed, after five (5) minutes the

Boiler Control will automatically return to the

Operating Mode.

5.

More Information about Adjustable Parameters

a. High Limit (

HL_

)

The Boiler Control is factory programmed with a

High Limit Setpoint of 180

°

F. The boiler turns

“off” when the boiler water temperature (

bt

) is

above this value. The High Limit setpoint is

adjustable between 140

°

and 240

°

F. The

Operating Setpoint (

P

) will equal the High

Limit Setpoint.

b. High Limit Differential (

HdF

)

The Cold Start Boiler Control is factory pro-

grammed with a Differential of 15

°

F. The

Differential is the number of degrees the boiler

temperature must decrease below the Operating

Setpoint before the boiler can restart. The

differential is adjustable between 10

°

and 30

°

F.

c. Circulator Overrun Time (

OR_

)

Circulator Overrun Time (also called “circulator

off delay” or “circulator post purge”) continues

circulator operation after a call for heat has

ended, sending excess heat from the boiler into

the priority zone. Ensure system piping and zone

panel settings allow water flow to the priority

zone after the call for heat ends. The Circulator

Overrun Time has a factor setting of 0 minutes

and is field adjustable between 0 and 10 minutes.

d. Circulator Pre-Purge Time (

PP_

)

When the boiler is warm [boiler water tempera-

ture higher than 140°F (adjustable using Start

Temperature parameter)] and there is a thermo-

stat call for heat, the system circulator is started

and boiler firing is delayed pre-purge minutes. If

the temperature drops below 140°F or there is a

DHW Call for Heat the boiler is started without

delay. Additionally, the boiler is started without

delay if the thermostat call for heat is initiated

when the boiler water temperature is less than

140°F. This feature helps save energy by

satisfying home heating needs with residual

Cold Start Boiler Control

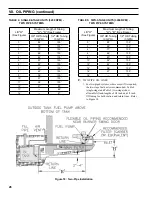

Adjustment mode Options

HL_

140-240°F

Adjust High Limit Setting

HdF

10-30°F

Adjust High Limit Differential

ZC_

dh

,

ZR

or

ELL

ZC and ZR Terminal Function

Or_

0-10 minutes

Pump Overrun Time

PP_

2-20 minutes

Pump Pre-purge Time

t_

140 - 180°F

Start Temperature

Pt_

On

or

Off

Priority Time

f-C

F

or

C

Select degrees F or C Mode

bac

Back to Operating Mode

Summary of Contents for LE DV Series

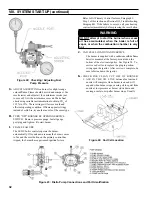

Page 5: ...5 I General Information Figure 1A LEDV Packaged Water Boiler with Beckett AFII Burner ...

Page 6: ...6 I General Information continued Figure 1B LEDV Packaged Water Boiler with Riello BF Burner ...

Page 19: ...19 v venting continued Figure 11 Vent Installation Figure 12 Vent Connector Un Assembled ...

Page 20: ...20 v venting continued Figure 13 Vent Connector Assembled Figure 14 Air Intake Installation ...

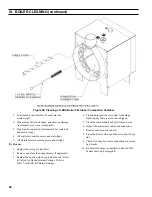

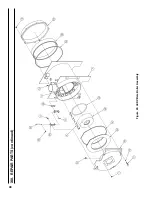

Page 48: ...48 xiii Repair Parts continued Figure 29 LEDV Bare Boiler Assembly ...

Page 50: ...50 xiii Repair Parts continued Figure 30 LEDV Boiler Jacket Insulation ...

Page 55: ...55 xiii Repair Parts continued Figure 33 Vent Kit Repair Parts ...

Page 60: ...60 U S Boiler Company Inc P O Box 3020 Lancaster PA 17604 1 888 432 8887 www usboiler net ...