18

V. VENTING (continued)

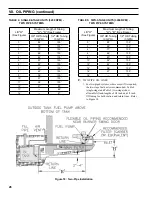

Table 3: Vent Pipe Part Numbers

4" Direct Oil™ Vent Pipe

Pipe Length

Part No.

5 Ft.

8113302

10 Ft.

8113303

15 Ft.

8113304

20 Ft.

8113305

Figure 10: Intake Terminal Location

6. Intake Terminal Location (Direct Vent only) - Locate

Air Intake Terminal not less than 12 inches to the

left, right, or bottom of the vent terminal. Do not

locate air intake terminal above vent terminal.

Intake terminal must be at least 12 inches above

grade plus snow accumulation; at least 1 foot from a

roof soffit; at least 3 feet from an inside corner of an

L-shaped structure. See Figures 9 and 10.

7. The LEDV must be vented with 4" Z-Flex Direct

Oil™ Vent. 20 feet is the maximum vent length

allowed. The vent pipe is available in 5, 10, 15, and

20 foot lengths. Table 3 lists vent part numbers.

8. The vent system must be completed with the Direct

Oil™ Vent Kit, which is shipped with the boiler.

Components of this kit are listed in the Repair Parts

Section of this manual.

DANGER

Vent pipe may not be spliced. Do not drill through

vent pipe. Do not operate boiler if vent pipe has

been crushed. Vent pipe must be completely

sealed. Do not operate boiler if vent pipe

insulation sleeve is damaged, frayed or missing.

B.

Vent Installation

(Direct Vent and Side-Wall Vent)

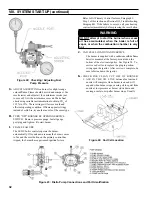

1. Install Vent Terminal. See Figure 11.

a. After determining the location from previous

Section, cut an opening in the wall for the vent

terminal.

•

Combustible wall: 8 inches diameter hole is

required to maintain a 1 inch clearance to

combustible materials.

•

Non-combustible wall: 6½ inches diameter

hole is required.

b. Secure 10" square trim plate to outside wall.

c. Insert the vent terminal through the opening until

the stop bead rest against the trim plate.

d. Slide the 10" square inside trim plate assembly

(fitted with gear clamp) onto the terminal pipe.

Summary of Contents for LE DV Series

Page 5: ...5 I General Information Figure 1A LEDV Packaged Water Boiler with Beckett AFII Burner ...

Page 6: ...6 I General Information continued Figure 1B LEDV Packaged Water Boiler with Riello BF Burner ...

Page 19: ...19 v venting continued Figure 11 Vent Installation Figure 12 Vent Connector Un Assembled ...

Page 20: ...20 v venting continued Figure 13 Vent Connector Assembled Figure 14 Air Intake Installation ...

Page 48: ...48 xiii Repair Parts continued Figure 29 LEDV Bare Boiler Assembly ...

Page 50: ...50 xiii Repair Parts continued Figure 30 LEDV Boiler Jacket Insulation ...

Page 55: ...55 xiii Repair Parts continued Figure 33 Vent Kit Repair Parts ...

Page 60: ...60 U S Boiler Company Inc P O Box 3020 Lancaster PA 17604 1 888 432 8887 www usboiler net ...