27

VII. OIL PIPING

A.

GENERAL

1. Use flexible oil line(s) so that burner can be re

-

moved without disconnecting the oil supply.

2. A supply line fuel oil filter is recommended as a

minimum for all firing rates but a pleated paper fuel

oil filter is recommended for the lowest firing rate

application to prevent nozzle fouling.

3. Use Flared fittings only.

DO NOT

use compression

fittings.

4. Use of a high efficiency micron filter (Garber or

equivalent) in addition to conventional filter is

highly recommended.

B.

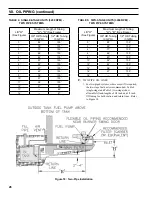

SINGLE-PIPE OIL LINES

1. Standard burners are provided with single-stage

3450 rpm fuel units with the bypass plug removed

for single-pipe installations.

2. The single-stage fuel unit may be installed single-

pipe with gravity feed or lift. Maximum allowable

lift is 8 feet. See Figure 17.

NOTICE

Oil piping must be absolutely airtight or leaks or

loss of prime may result. Bleed line and fuel unit

completely.

Figure 17: Single-Pipe Installation

Summary of Contents for LE DV Series

Page 5: ...5 I General Information Figure 1A LEDV Packaged Water Boiler with Beckett AFII Burner ...

Page 6: ...6 I General Information continued Figure 1B LEDV Packaged Water Boiler with Riello BF Burner ...

Page 19: ...19 v venting continued Figure 11 Vent Installation Figure 12 Vent Connector Un Assembled ...

Page 20: ...20 v venting continued Figure 13 Vent Connector Assembled Figure 14 Air Intake Installation ...

Page 48: ...48 xiii Repair Parts continued Figure 29 LEDV Bare Boiler Assembly ...

Page 50: ...50 xiii Repair Parts continued Figure 30 LEDV Boiler Jacket Insulation ...

Page 55: ...55 xiii Repair Parts continued Figure 33 Vent Kit Repair Parts ...

Page 60: ...60 U S Boiler Company Inc P O Box 3020 Lancaster PA 17604 1 888 432 8887 www usboiler net ...