41

XI. BOILER CLEANING

NOTICE

BURNER SHUTDOWN: Open Service Switch

to turn off burner.

manual Oil Supply Valve should be closed

and Electric Service to boiler turned off.

A

.

General

. Inspection, service and cleaning should be

conducted annually. Turn off electric power and close

oil supply valve while conducting service or

maintenance.

B.

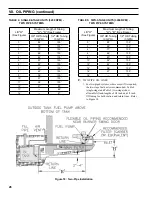

CLEAN THE FIRETUBES, see Figure 28.

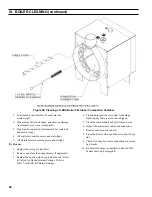

1. For access to fireside of boiler, separate two halves

of Burner Swing Door Interlock wiring harness

apart. Remove screws securing burner harness cable

clamps to jacket right side panel. Remove 5/16" -18

x 3" lg. cap screws and washers holding door closed.

2. To OPEN Burner Swing Door Fully, raise burner

harness over top edge of door. If burner is equipped

with flexible fuel line(s), swing door open.

3. It is NOT necessary to remove the vent connector

from the smoke box to clean boiler. If necessary,

remove the vent connector if there is evidence of

heavy soot accumulation in the boiler or to inspect

base of chimney for condensate or accumulation of

debris.

4. Prior to cleaning boiler, lay a protective cloth or

plastic over combustion chamber liner.

5. Using a 1 1/2" diameter wire brush (30" handle) to

clean firetubes. Measure 15" from end of brush

opposite handle, and mark handle. DO NOT allow

this mark to go past front end of firetube during

cleaning, or brush will hit rear door insulation piece.

C.

CLEAN THE COMBUSTION CHAMBER, see

Figure 28.

Using wire or fiber bristle brush, clean inside of

combustion chamber. DO NOT let brush hit rear door

insulation piece or combustion chamber liner.

D.

AFTER CLEANING

Vacuum debris inside bottom of rear door, remove

protective cloth, and vacuum remaining fireside of

boiler as necessary. BE CAREFUL not to damage liner

or rear door insulation piece. Inspect front and rear door

insulation pieces, front door gaskets and combustion

chamber liner for damage. Replace any damaged pieces

immediately.

E.

CLOSE AND SECURE BURNER SWING DOOR.

CAUTION:

Do not start burner unless burner swing door is

securely closed. Close door, install 5/16" -18 lg. cap

screws and washers, and tighten securely. Door should

be parallel to tubesheet when viewed from top and

sides. Reconnect two halves of Swing Door Interlock.

F.

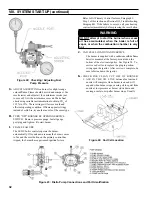

Vent/Air Intake System.

Inspect for obstructions, soot

accumulation, proper support, and deterioration of pipe,

fittings, and joints.

1. Inspect inside of vent pipe.

a. Disconnect appliance adapter from boiler flue

collar.

b. Remove any obstructions and clean with a wire

brush as required.

c. Reconnect appliance adapter to boiler flue collar

as detailed in Section V: Venting/Air Intake

Piping.

2. Clean terminal screens. Terminals must be free of

obstruction, undamaged, with screens securely in

place.

WARNING

All boiler cleaning must be completed with burner service switch turned off. Boilers equipped with burner

swing door have a potential hazard which can cause severe property damage, personal injury or loss of

life if ignored. Before opening swing door, turn off service switch to boiler to prevent accidental firing of

burner outside the combustion chamber. Before opening burner swing door, separate two halves of burner

swing door interlock wiring harness. Be sure to tighten swing door fastener completely when service is

completed.

WARNING

This boiler must be properly vented and connected to an approved vent system in good condition. DO

NOT operate boiler with the absence of an approved vent system.

The interior of the venting and air intake systems must be inspected and cleaned before the start of the

heating season and should be inspected periodically throughout the heating season for any obstructions.

Clean and unobstructed venting and air intake systems are necessary to allow noxious fumes that could

cause injury or loss of life to vent safely and will contribute toward maintaining the boiler's efficiency.

Summary of Contents for LE DV Series

Page 5: ...5 I General Information Figure 1A LEDV Packaged Water Boiler with Beckett AFII Burner ...

Page 6: ...6 I General Information continued Figure 1B LEDV Packaged Water Boiler with Riello BF Burner ...

Page 19: ...19 v venting continued Figure 11 Vent Installation Figure 12 Vent Connector Un Assembled ...

Page 20: ...20 v venting continued Figure 13 Vent Connector Assembled Figure 14 Air Intake Installation ...

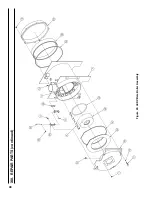

Page 48: ...48 xiii Repair Parts continued Figure 29 LEDV Bare Boiler Assembly ...

Page 50: ...50 xiii Repair Parts continued Figure 30 LEDV Boiler Jacket Insulation ...

Page 55: ...55 xiii Repair Parts continued Figure 33 Vent Kit Repair Parts ...

Page 60: ...60 U S Boiler Company Inc P O Box 3020 Lancaster PA 17604 1 888 432 8887 www usboiler net ...