MAINTENANCE MANUAL

131

STE 85357

!

CAUTION

• Be sure to use the grease designated by Toshiba Machine.

Increase in internal pressure will adversely affect the starting torque and damage the

internal seal. To avoid this, be sure to observe the grease filling volume.

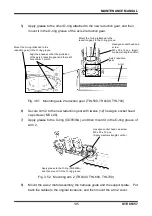

5)

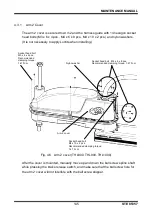

Secure Arm 1 to the base with sixteen (16) hexagon socket head cap screws

(M4 x 20). Apply grease to the O-ring (CO0545), and then mount it to the base

groove side surface.

Fig. 3.49 Mounting arm 1 and O-ring (THL500, THL600, THL700)

6)

Connect the connectors (J1AS and J1BS) of the cables.

7)

Mount the axis 1 motor assembly. (See

“Para. 3.4.4, Mounting Axis 1 Motor.”)

8)

After changing Axis 1 motor, move Arm 1 by hand and check that there is no

abnormal sound .

Hexagon socket head cap screw

M4 x 20 x 16 pcs.

(Apply medium strength Loctite.)

Base groove side surface

O-ring

CO0545