MAINTENANCE MANUAL

180

STE 85357

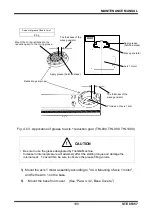

Fig. 4.44 Dismounting ball screw spline unit (THL800, THL900, THL1000)

!

CAUTION

• When the ball screw nut integrated with the ball screw spline shaft is disconnected, take

utmost care not to cause the ball screw spline shaft to come off. Otherwise, the ball in the

ball screw nut will drop and the ball screw nut integrated with the ball screw spline shaft

cannot function any further.

9)

Remove six (6) hexagon socket head bolts (M4 x 12) securing the ball spline nut,

and pull out the ball spline nut downward.

If the ball spline nut is hard to remove, screw a bolt into the ball spline nut tap

(M4) to remove it.

10) Disconnect the axis 4 nut pulley secured to the ball spline nut with six (6)

hexagon socket head bolts (M5 x 12). When it is hard to disconnect, screw the

bolt into the tap for disassembly (M4) machined on the pulley and disconnect.

Stopper

Hexagon socket head bolts

M4 x 12 x 6 pcs.

Washer

Do not pull out.

Stopper

Stopper

Axis 3 bracket

Ball screw

spline shaft

Ball screw nut

Hexagon socket

head bolts

M4 x 12 x 4 pcs.