MAINTENANCE MANUAL

40

STE 85357

5)

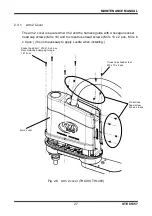

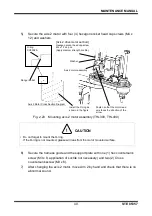

Secure the axis 2 motor with four (4) hexagon socket head cap screws (M4 x

12) and washers.

Fig. 2.20 Mounting axis 2 motor assembly (THL300, THL400)

!

CAUTION

• Do not forget to mount the O-ring.

If the O-ring is not mounted, grease will leak from the motor mounted surface.

6)

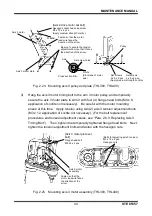

Secure the harness guide and the support plate with one (1) hex countersunk

screw (M3 x 8, application of Loctite not necessary) and two (2) Cross

countersunk screw (M3 x 6).

7) After changing the axis 2 motor, move Arm 2 by hand and check that there is no

abnormal sound.

[Axis 2 drive motor set bolt]

Hexagon socket head cap screw

M4 x 12 x 4 pcs.

(Apply medium strength Loctite.)

Axis 2 Motor Cross Section Diagram

Install the O-ring as

shown in the figure.

Axis 2 motor assembly

Washer

Fasten so that the motor lead

wire faces the direction of the

arrow.

O-ring

CO0538A

Flange rabbet