DP4500/3500 ERROR CODES AND SELF-DIAGNOSIS

1 - 22

December 2000 © TOSHIBA TEC

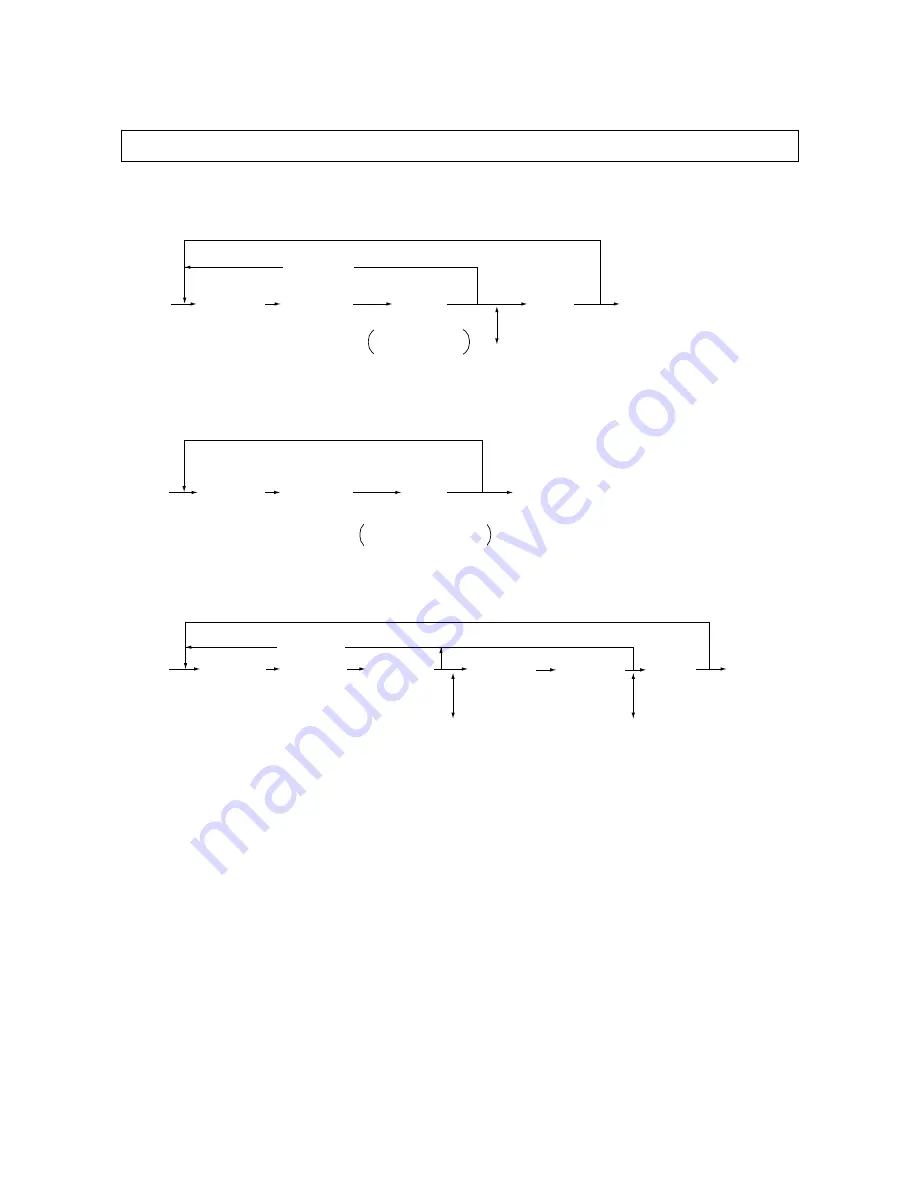

1.2.5 Setting mode (08)

The items in the setting code list can be set or changed in this setting mode (08).

<Procedure>

Group 1

Group 2

Group 3

[0] [8]

[POWER]

[Digital key]

(Code)

[C/S]

(Corrects value)

[SET]

or

[INTERRUPT]

[0] [9]

(Exit)

[START]

[CANCEL]

[Digital key]

or

[Select icon]

Sets or

changes value

(Stores value in RAM)

[0] [8]

[POWER]

[Digital key]

(Code)

[START]

[SET]

or

[INTERRUPT]

[0] [9]

(Exit)

Adjustment value

cannot be changed

[0] [8]

[POWER]

[Digital key]

(Code)

[CANCEL]

[START]

[Digital key]

(1st setting)

[C/S]

(Corrects value)

[START]

[Digital key]

(2nd setting)

[SET]

or

[INTERRUPT]

[0] [9]

(Exit)

(Stores value in RAM)

[C/S]

(Corrects value)

Summary of Contents for DP3500

Page 91: ...DP4500 3500 PREVENTIVE MAINTENANCE 3 12 December 2000 TOSHIBA TEC ...

Page 95: ...DP4500 3500 SUPPLIES 4 4 December 2000 TOSHIBA TEC ...

Page 213: ...DP4500 3500 TROUBLESHOOTING 5 118 December 2000 TOSHIBA TEC ...

Page 253: ...DP4500 3500 UPDATING THE FIRMWARE 6 40 December 2000 TOSHIBA TEC ...

Page 256: ...DP4500 3500 WIRE HARNESS CONNECTION DIAGRAMS 7 4 December 2000 TOSHIBA TEC ...