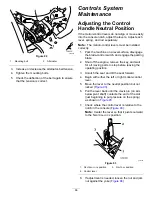

9.

While applying slight rearward pressure on

the motion-control lever, turn the head of the

adjustment bolt in the appropriate direction until

the control lever is centered in the N

EUTRAL

-

LOCK

position (

Note:

Keeping rearward pressure on the lever

keeps the pin at the end of the slot and allows

the adjustment bolt to move the lever to the

appropriate position.

10.

Tighten the nut and jam nut (

11.

Repeat for the opposite side of the machine.

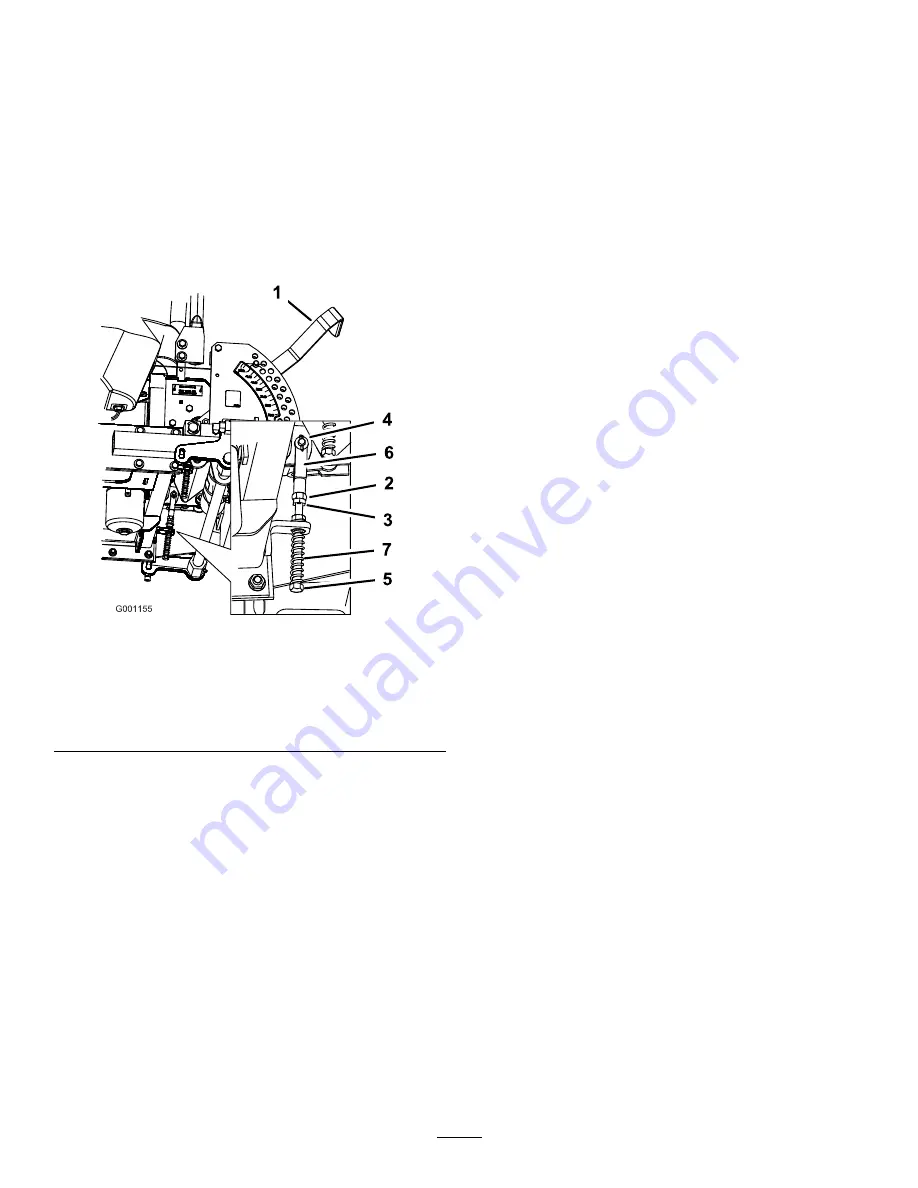

g001155

Figure 94

1.

Height-of-cut lever

5.

Adjustment bolt

2.

Nut against yoke

6.

Yoke

3.

Jam nut

7.

Spring

4.

Clevis pin in slot

Hydraulic System

Maintenance

Hydraulic System Safety

•

Seek immediate medical attention if fluid is injected

into skin. Injected fluid must be surgically removed

within a few hours by a doctor.

•

Ensure that all hydraulic-fluid hoses and lines are

in good condition and all hydraulic connections

and fittings are tight before applying pressure to

the hydraulic system.

•

Keep your body and hands away from pinhole

leaks or nozzles that eject high-pressure hydraulic

fluid.

•

Use cardboard or paper to find hydraulic leaks.

•

Safely relieve all pressure in the hydraulic system

before performing any work on the hydraulic

system.

Hydraulic-Fluid

Specifications

Hydraulic-Fluid Type:

Toro

®

HYPR-OIL

™

500

hydraulic fluid or Mobil

®

1 15W-50 fluid

Important:

Use the specified fluid. Other fluids

could damage the hydraulic system.

Hydraulic-System Fluid Capacity:

3.9 L (132 fl oz)

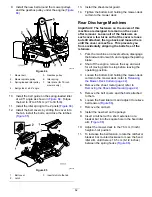

Checking the

Hydraulic-Fluid Level

Service Interval:

After the first 8 hours

Every 25 hours

Note:

You can check the hydraulic fluid when the

fluid is warm or it is cold. The baffle inside the tank

has 2 levels depending if the fluid is warm or cold.

1.

Park the machine on a level surface, disengage

the blade-control switch, and engage the parking

brake.

2.

Shut off the engine, remove the key, and wait

for all moving parts to stop before leaving the

operating position.

3.

Clean the area around the filler neck of the

hydraulic tank (

4.

Remove the cap from the filler neck and look

inside to check if there is fluid in the reservoir

(

).

5.

If there is no fluid, add fluid to the reservoir until

it reaches the cold level of the baffle.

67

Summary of Contents for Z Master Professional 7000 Series

Page 2: ......

Page 84: ...Schematics g012068 Wire Diagram Rev A 82...

Page 86: ......

Page 177: ...Schaltbilder g012068 Schaltbild Rev A 91...

Page 270: ...Sch mas g012068 Sch ma de c blage Rev A 92...

Page 271: ...Remarques...

Page 272: ...Remarques...

Page 274: ......

Page 362: ...Schema s g012068 Elektrisch schema Rev A 88...

Page 364: ......