Adjusting the Electric

Clutch

Service Interval:

Every 500 hours

The clutch is adjustable to ensure proper engagement

and proper braking.

1.

Park the machine on a level surface, disengage

the blade-control switch, and engage the parking

brake.

2.

Shut off the engine, remove the key, and wait

for all moving parts to stop before leaving the

operating position.

3.

Unlatch the seat and tip it forward.

4.

Loosen the front engine panel knobs and

remove the panel.

5.

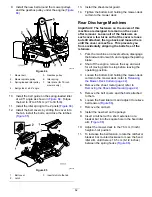

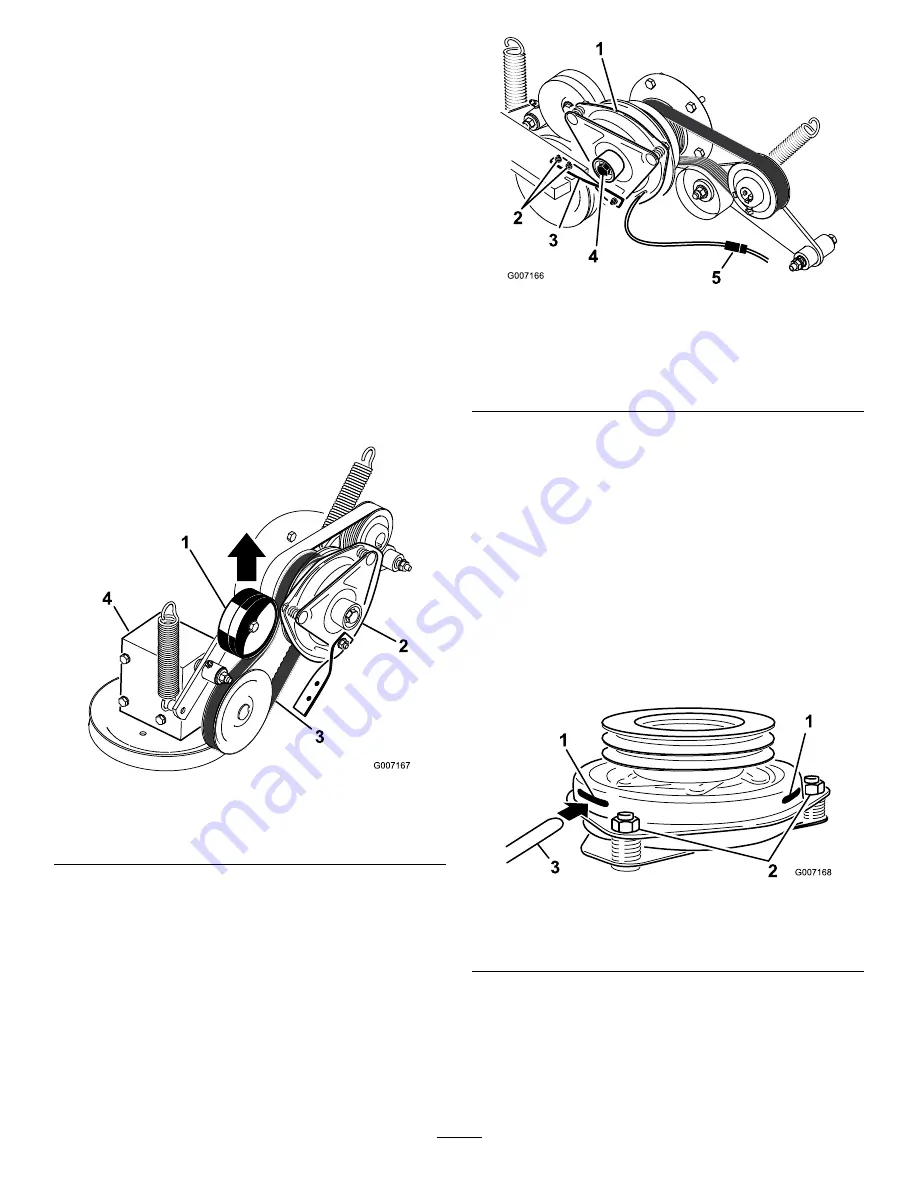

Pull up on the spring-loaded idler pulley for the

PTO-drive belt and remove the belt from the

clutch pulley (

g007167

Figure 77

1.

Spring-loaded idler pulley

3.

PTO-drive belt

2.

Clutch

4.

Gearbox

6.

Unplug the electric connection for the clutch

(

).

7.

Remove the 2 bolts holding the rubber clutch

strap to the mower frame (

).

8.

Remove the center bolt holding the clutch to

the engine shaft and remove the clutch and key

(

).

g007166

Figure 78

1.

Clutch

4.

Clutch center bolt

2.

2 bolts and nuts for clutch

strap

5.

Electrical connection

3.

Rubber clutch strap

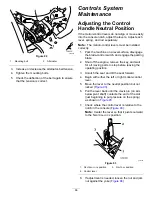

9.

Insert a 0.381 to 0.533 mm (0.015 to 0.021 inch)

feeler gauge through an inspection slot in the

side of the assembly (

).

Note:

Make sure that it is between the armature

and the rotor friction surfaces.

10.

Tighten the locknuts until there is slight binding

on the feeler gauge but it can be moved easily

within the air gap (

).

11.

Repeat this for the remaining slots.

12.

Check each slot again and make slight

adjustments until the feeler gauge between

the rotor and armature has very slight contact

between them.

g007168

Figure 79

1.

Slot

3.

Feeler gauge

2.

Adjusting nut

13.

Install the clutch to the engine shaft with the key.

14.

Apply thread-locking adhesive to the center bolt.

15.

While holding the crank shaft at the back of the

machine, install the center bolt and torque it to

68 N∙m (50 ft-lb) (

58

Summary of Contents for Z Master Professional 7000 Series

Page 2: ......

Page 84: ...Schematics g012068 Wire Diagram Rev A 82...

Page 86: ......

Page 177: ...Schaltbilder g012068 Schaltbild Rev A 91...

Page 270: ...Sch mas g012068 Sch ma de c blage Rev A 92...

Page 271: ...Remarques...

Page 272: ...Remarques...

Page 274: ......

Page 362: ...Schema s g012068 Elektrisch schema Rev A 88...

Page 364: ......