3 | Connections and Setup

STp.1120n User’s Guide

42

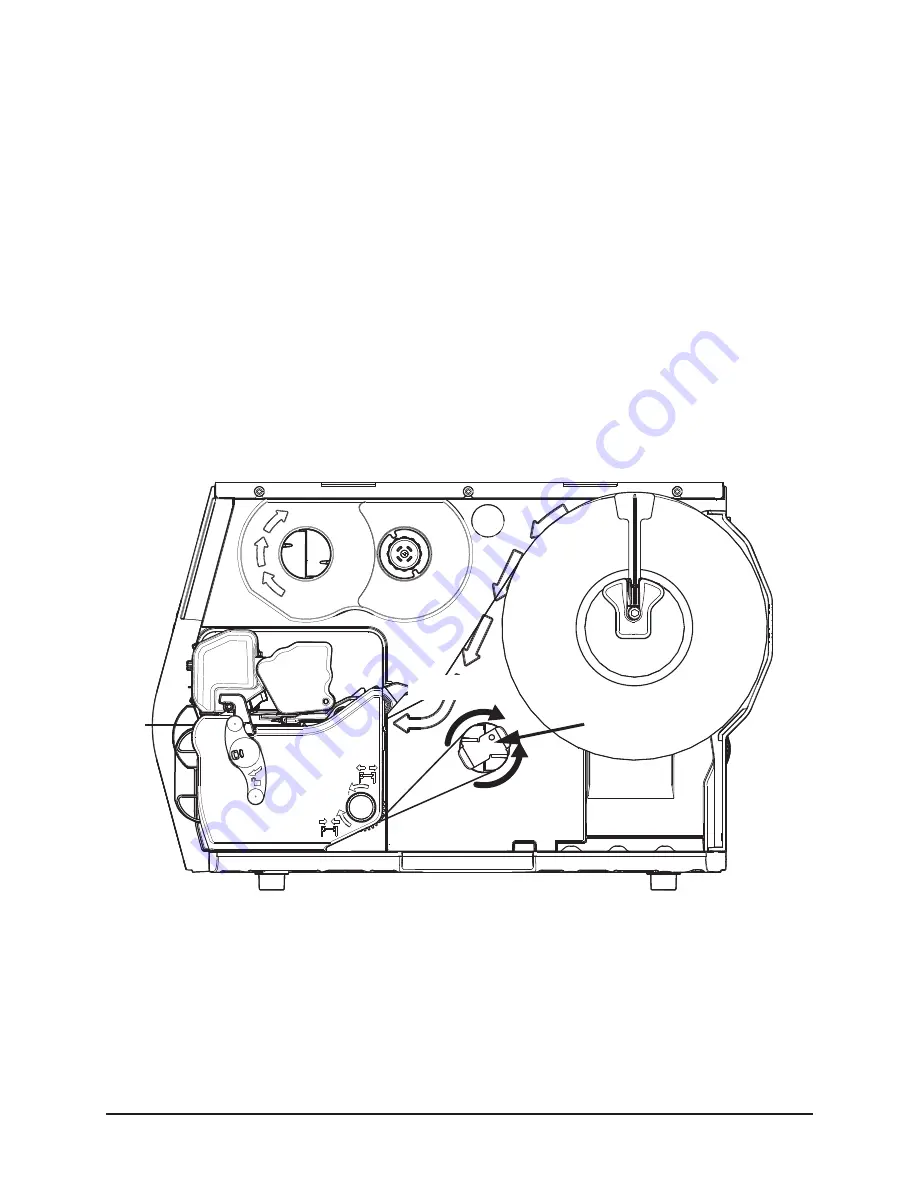

Optional Rewinder

The rewinder is designed to rewind in either direction but the direction must be set

through the menu.

Note:

Either the peel plate or the rewinder plate must be installed.

Installation of Media

1. Route the media through the platen carriage assembly.

Note:

Follow the instructions for the installed media hanger.

2. Route the media under the platen carriage and around the rewinder shaft.

3. Remove the metal clasp and wind the media around the rewinder shaft in the

desired direction.

Figure: 3 - 36 Rewinder

4. Insert the edge of the media into one of the two grooves on the rewinder shaft.

Counter Clockwise

Clockwise

Metal Clasp

Summary of Contents for STP.1120N

Page 1: ...STp 1120n User s Guide...

Page 2: ......

Page 4: ......

Page 6: ......

Page 96: ...3 Connections and Setup STp 1120n User s Guide 86...

Page 132: ...4 Menu System STp 1120n User s Guide 122...

Page 136: ...5 Cleaning and Maintenance STp 1120n User s Guide 126...

Page 150: ...7 Terms and Definitions STp 1120n User s Guide 140...

Page 156: ...8 Appendix A STp 1120n User s Guide 146...

Page 157: ......

Page 158: ......