4-21

CSM-200

6.

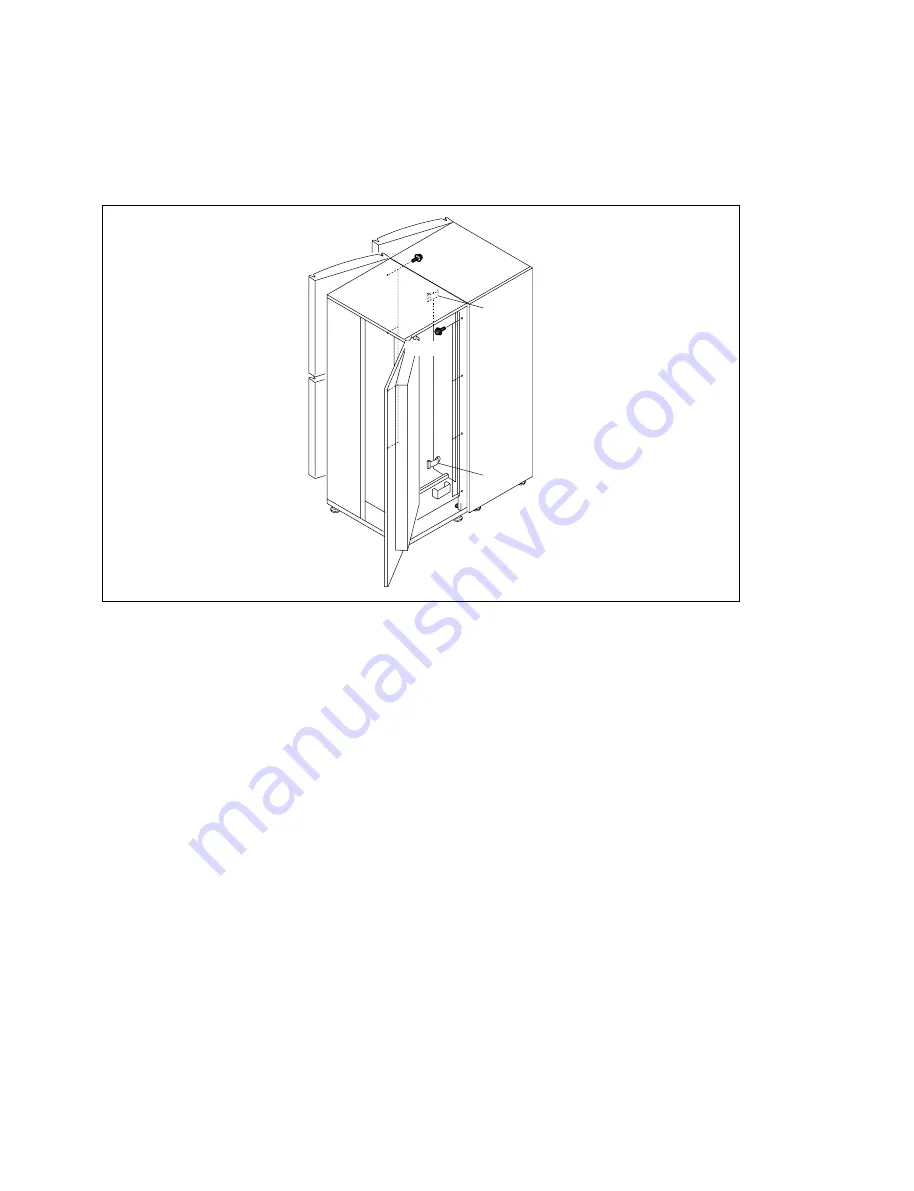

Tighten both of the Basic storage system and the extension console with the eight hexagon head cap

bolts (M4

x

8) supplied with the extension console.

7.

Connect the two flat cables (50-pins and 26-pins) coming from the Basic storage system to the

connectors of the extension console.

8.

Attach all of the blank panels (1U) of the extension console that are removed in step 4.

M4

x

8

M4

x

8

26 pin

50 pin