Gantry axes (G1)

6.3 Referencing and synchronizing gantry axes

Turning, Milling, Nibbling

98

Function Manual, 11/2012, 6FC5397-1CP10-5BA0

Absolute encoder

During the synchronization compensatory motion, all the axes in the gantry axis grouping (in

the decoupled state) also traverse to the reference point value of the leading axis, which is

defined in the following machine data:

MD34100 REFP_SET_POS (reference point value/destination point for distance-coded

system)

The absolute encoders and distance-coded encoders of the leading axis will be set to the

current actual position of the leading axis or to the reference point value; either of these

options is set using the following machine data:

MD34330 REFP_STOP_AT_ABS_MARKER

(distance-coded linear measuring system without destination point)

Activation of axis compensations

Compensation functions can be activated for both the leading axis and the synchronized

axis. Compensation values are applied separately for each individual gantry axis. These

values must therefore be defined and entered for the leading axis and the synchronized axes

during start-up.

The compensations do not become operative internally in the control until the axis is

referenced or the gantry grouping synchronized. The following applies:

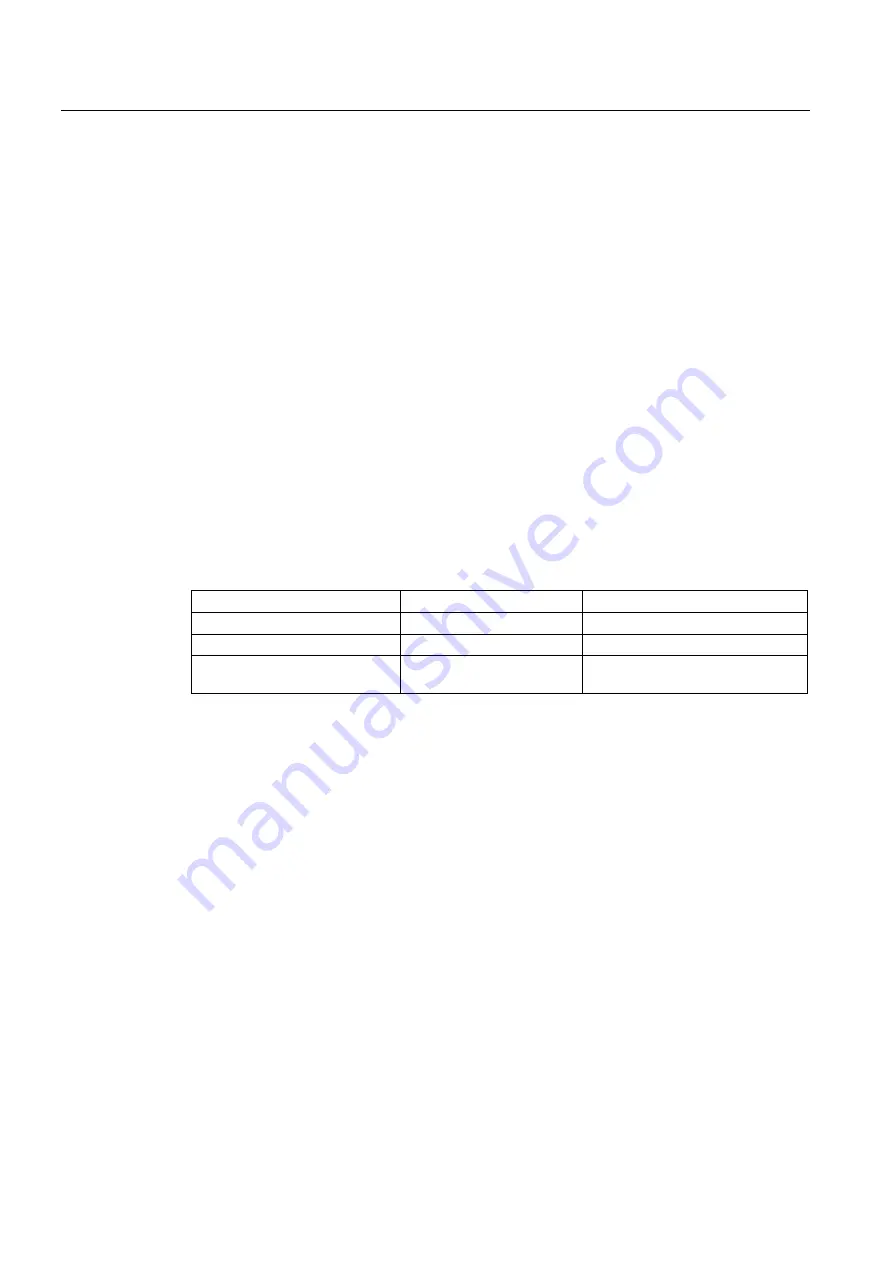

Compensation type

Takes effect when

PLC interface signal

Backlash compensation

Axis is referenced

"Referenced/Synchronized"

LEC

Axis is referenced

"Referenced/synchronized"

Sag compensation

Gantry grouping is

synchronized

"Gantry grouping is synchronized"

If active compensation causes the synchronized axis to move, a traverse command is

displayed for the synchronized axis, independently of the leading axis.

Monitoring functions effective

Analogous to normal NC axes, the following monitoring functions do not take effect for gantry

axes until the reference point is reached (IS "Referenced/Synchronized"):

●

Working area limits

●

Software limit switch

●

Protection zones

The axial machine data values are used as monitoring limit values for the synchronized axis

as well.