Spindle (S1)

20.2 Spindle modes

Turning, Milling, Nibbling

Function Manual, 11/2012, 6FC5397-1CP10-5BA0

347

20.2.3

Spindle positioning mode

When is positioning mode used?

The spindle positioning mode stops the spindle at the defined position and activates the

position control, which remains active until it is deactivated. With the SPOS =..... program

function, the spindle is in positioning mode (see also Section "Programming").

Block change

The block change is carried out when all functions programmed in the block have reached

their end criterion (e.g. axis traverse completed, all auxiliary functions acknowledged by

PLC) and the spindle has reached its position (IS "Exact stop fine" for spindle (V390x

0000.7)).

Requirements

A spindle position actual value encoder is absolutely essential.

Positioning from rotation

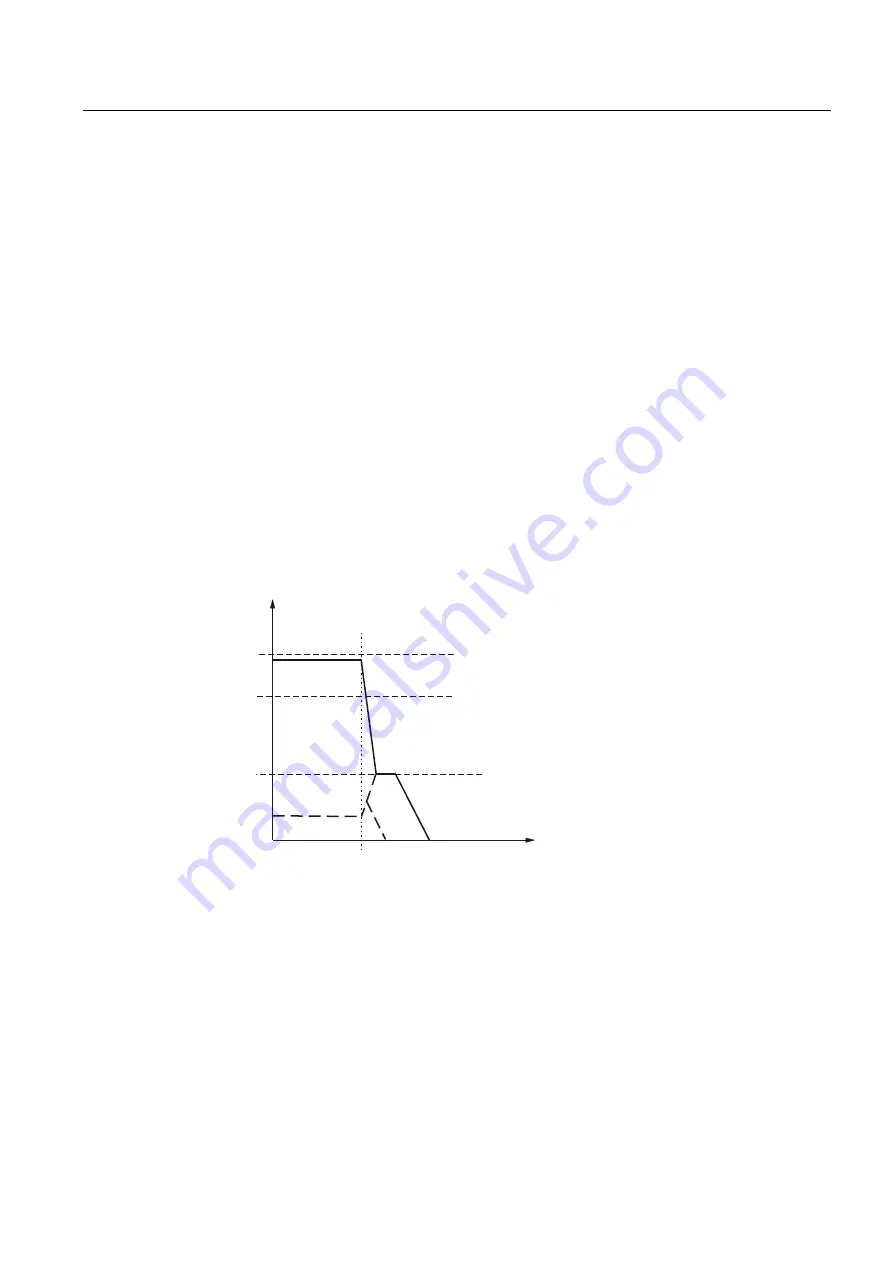

D

D

0'(1&B)5(4B/,0,7B/2:

HQFRGHUOLPLWIUHTXHQF\UHV\QFKURQL]DWLRQ

YDOXHRI0'

3KDVHWR

0'63,1'B326&75/B9(/2

SRVLWLRQFRQWURODFWLYDWLRQVSHHG

6326

0'(1&B)5(4B/,0,7

HQFRGHUOLPLWIUHTXHQF\

7LPHV

6SHHG

UHYPLQ

Figure 20-3 Positioning from rotation at different speeds

Sequence

Phase 1: Spindle rotates at a lower speed than the encoder limit frequency. The spindle is

synchronized. It is set to control mode. Process continues with Phase 2.

Phase 1a: Spindle rotates at a lower speed than the position control activation speed. The

spindle is synchronized. It is set to control mode. The rest of the sequence is possible via 4a.