Compensation (K3)

11.2 Backlash compensation

Turning, Milling, Nibbling

208

Function Manual, 11/2012, 6FC5397-1CP10-5BA0

Effectiveness

Backlash compensation is always active in all operating modes after reference point

approach.

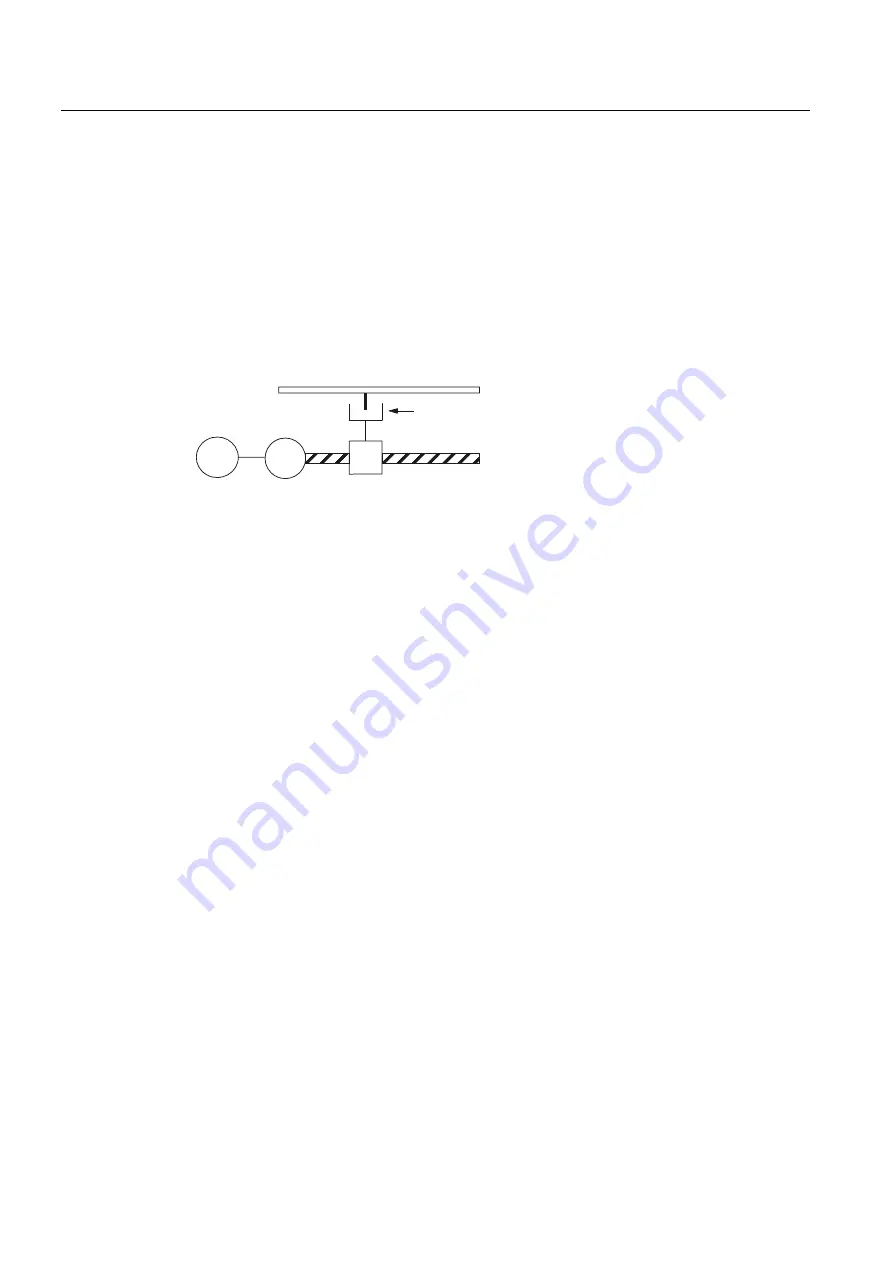

Positive backlash

The encoder leads the machine part (e.g. table). Since the actual position acquired by the

encoder also leads the real actual position of the table, the table travels too short a distance

(see diagram below). The backlash compensation value must be entered as a positive value

here (= normal case).

(QFRGHUDFWXDOYDOXHOHDGVWKHUHDODFWXDOYDOXHWDEOH

7KHWDEOHGRHVQRWWUDYHUVHIDUHQRXJK

7DEOH

(QFR

GHU

0

%DFNODVK

Figure 11-1 Positive backlash (normal case)

Negative backlash

The encoder lags behind the machine part (e.g. table); the table then travels too far. The

correction value entered is negative.

High backlash compensation values

The user has the option of applying the backlash compensation value gradually in several

increments when the relevant axis reverses direction. This prevents an excessive setpoint

step change from causing specific axis errors.

The contents of the axis-specific MD36500 ENC_CHANGE_TOL determine the increment

with which the backlash compensation value (MD32450 BACKLASH) is applied. Please note

that the backlash compensation is fully calculated only after n servo cycles

(n=MD32450/MD36500). An excessive time span can cause the triggering of standstill

monitoring alarms. If MD36500 is greater than MD32450, the compensation is performed in

a servo cycle.