Compensation (K3)

11.3 Interpolatory compensation

Turning, Milling, Nibbling

Function Manual, 11/2012, 6FC5397-1CP10-5BA0

215

6DJLQQHJ<

GLUHFWLRQEHFDXVH

RIVHOIZHLJKW

=

<

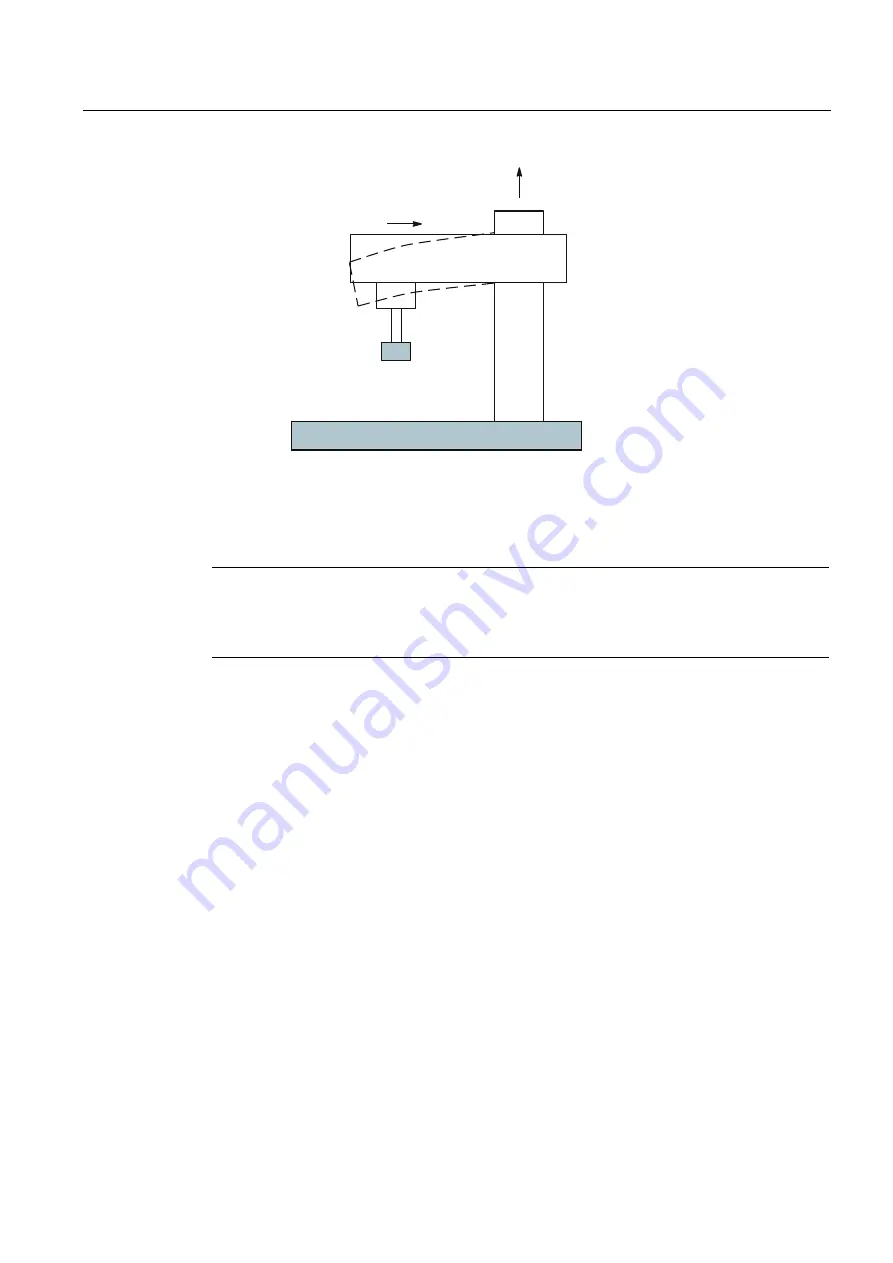

Figure 11-4 Example of sag caused by own weight

Depending on the requirement, several compensation relations can be defined for one axis.

The total compensation value results from the sum of all the compensation values of this

axis.

Note

You can read the compensation value that is currently effective on the user interface under

the "Sag/temperature" variable. To do this, select softkey "System" followed by "Service

Display" → "Service Axes".

Setting options

The many ways in which the compensation value for sag compensation can be

produced/influenced are listed below (see diagram below).

1.

An axis can be defined as the input variable (base axis) for several compensation tables

(settable via system variables).

2.

An axis can be defined as the recipient of the output variable (compensation axis) of

several compensation tables (settable via system variable). The total compensation value

is derived from the sum of the individual compensation values.

The following definition applies for the maximum number of possible compensation

tables:

Total maximum number of tables available for all axes: 2

3.

An axis can be both a base axis and a compensation axis at any one time. The

programmed (required) position setpoint is always used to calculate the compensation

values.

4.

The scope of action of the compensation (starting and end position of the base axis) and

the distance between the interpolation points can be defined for every compensation

table (settable via system variables).

5.

Compensation can be direction-dependent (settable via system variables).