Axis Monitoring (A3)

2.4 Monitoring of static limits

Turning, Milling, Nibbling

50

Function Manual, 11/2012, 6FC5397-1CP10-5BA0

Effect

If the number of zero mark errors entered in MD36310 ENC_ZERO_MONITORING is

reached for a measuring system, alarm 25020 "Zero mark monitoring" is triggered.

The affected axis/spindle is brought to a standstill using a rapid stop (with open position

control loop) along a speed setpoint ramp. The braking ramp duration is specified in

MD36610 AX_EMERGENCY_STOP_TIME.

If the axis is assigned to an interpolatory grouping with other axes, then these are also

braked using a rapid stop with following error reduction (default for partial position setpoint =

0).

Causes of errors

●

MD36300 ENC_FREQ_LIMIT (encoder limit frequency) set too high.

●

Encoder cable damaged.

●

Encoder or encoder electronics defective.

Note

When an error occurs in the measuring circuit, interface signal "Referenced/synchronized 1"

(V390x 0000.4) is cancelled; i.e. the axis must be re-referenced.

2.4

Monitoring of static limits

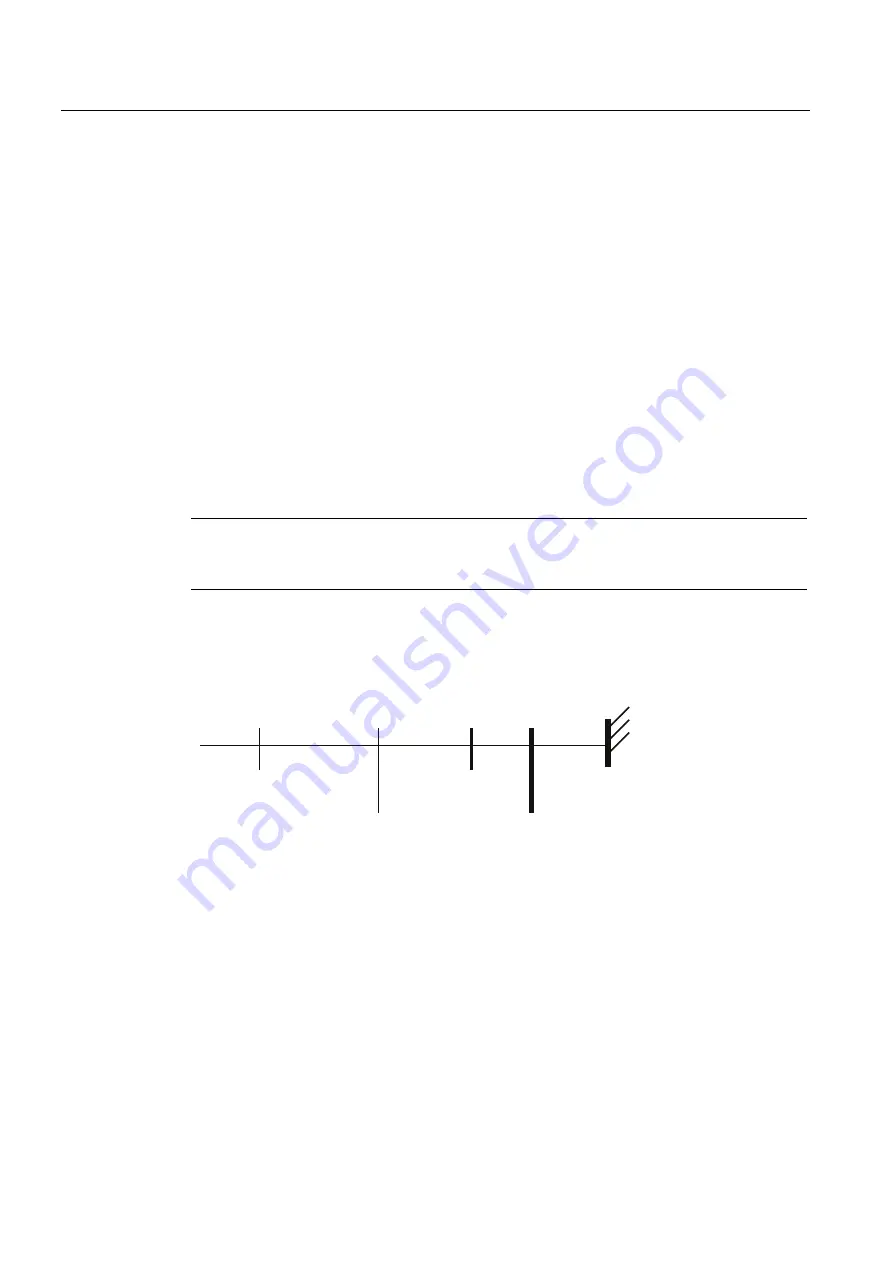

(0(5*(1&<6723

0HFKDQLFDO

HQGRIWUDYHUVLQJ

UDQJH

+:OLPLWVZLWFK

VW6:OLPLWVZLWFK

QG6:OLPLWVZLWFK

FDQEHDFWLYDWHGYLD3/&

Figure 2-3

Overview of travel limits of a linear axis

2.4.1

Hardware limit switches

Function

Every axis has a hardware limit switch for each traversing direction, which prevents the slide

from moving out of the slide bed.