Gantry axes (G1)

6.7 Example

Turning, Milling, Nibbling

110

Function Manual, 11/2012, 6FC5397-1CP10-5BA0

In addition, the following steps must be taken:

●

RESET

●

Read off values in machine coordinate system:

e.g.

X = 0.941

Y = 0.000

XF = 0.000

●

Enter the X value of the leading axis (axis 1) with inverted sign in the machine data of the

synchronized axis (axis 3):

MD34090 REFP_MOVE_DIST_CORR = - 0.941

Note

This MD is effective after POWER ON. To avoid having to perform a POWER ON in

advance, this value can also be entered in the following machine data:

MD34080 REFP_MOVE_DIST (reference point distance)

The MD is then valid after a RESET.

●

Start referencing again for axis 1 with the modified machine data

●

Wait until message "10654 Channel 1 Waiting for synchronization start" appears

●

At this point, the NCK has prepared axis 1 for synchronization and sends the same

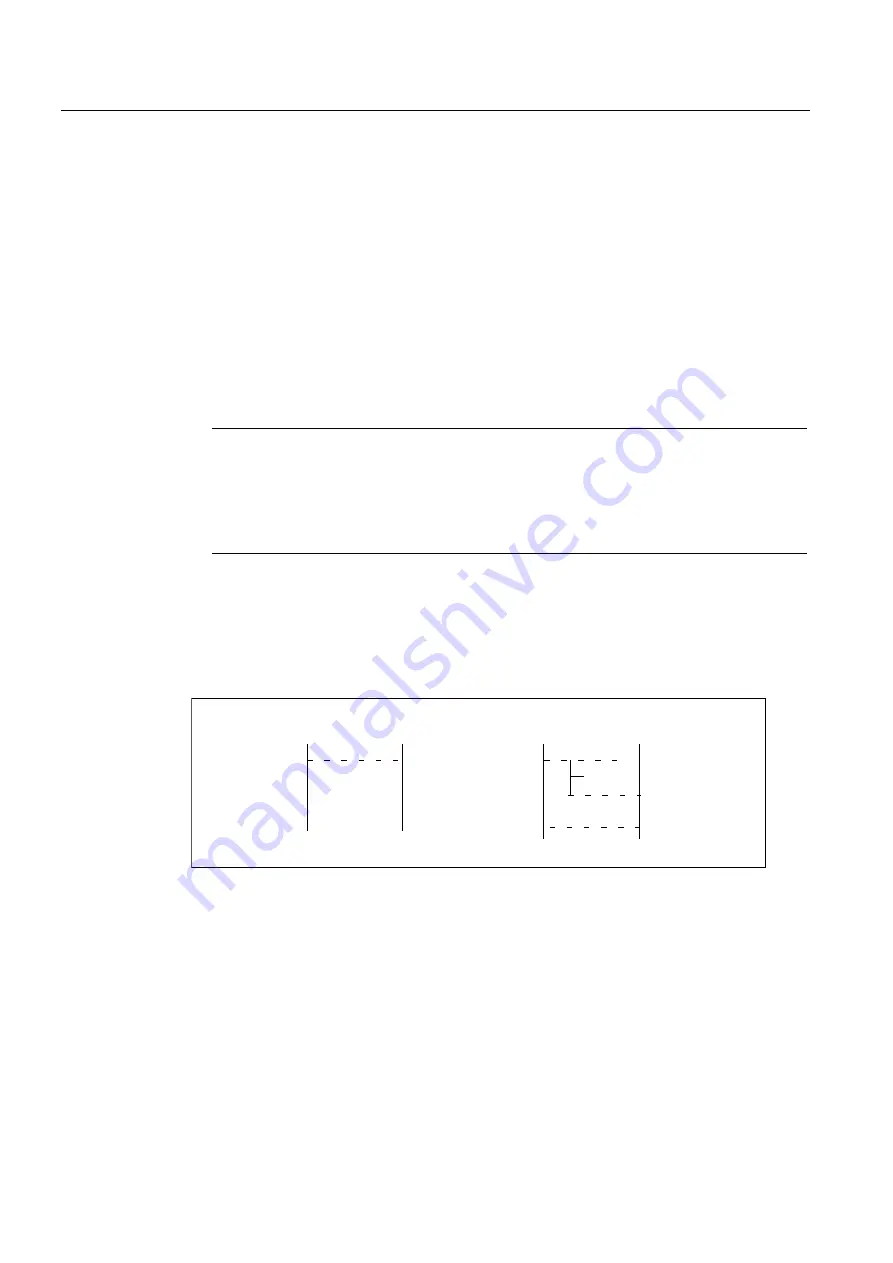

interface signal as shown in the image above:

●

Examine actual positions of machine. Case A or B might apply:

!5

5!

GLII

&DVH%

!

$

$

&DVH$

!

$

$

Figure 6-8

Possible results of referencing the leading axis

If Case A applies, the synchronization process can be started immediately. See step "Start

synchronization". If Case B applies, the offset "diff" must be calculated and taken into

account:

●

Measuring of diff

●

By using two appropriate, right-angled reference points R and R" in the machine bed (at

the right of the image), the difference in position can be traversed in JOG. The diff offset

can then be read as the difference in the position display. The diff offset must be entered

in the machine data of axis 3 (synchronized axis):

MD34100 REFP_SET_POS