Operating Modes, Program Operation (K1)

10.3 Processing a part program

Turning, Milling, Nibbling

Function Manual, 11/2012, 6FC5397-1CP10-5BA0

187

The start signal must be set to logical 0 by the user once the ASUB has been completed or if

an error has occurred.

Note

The call of the ASUB PI service must have been completed before an ASUB may be started.

Initialization

The initialization is performed via the ASUB PI service, see also Section "Starting PI services

in the NCK area (A2)".

Starting an ASUB

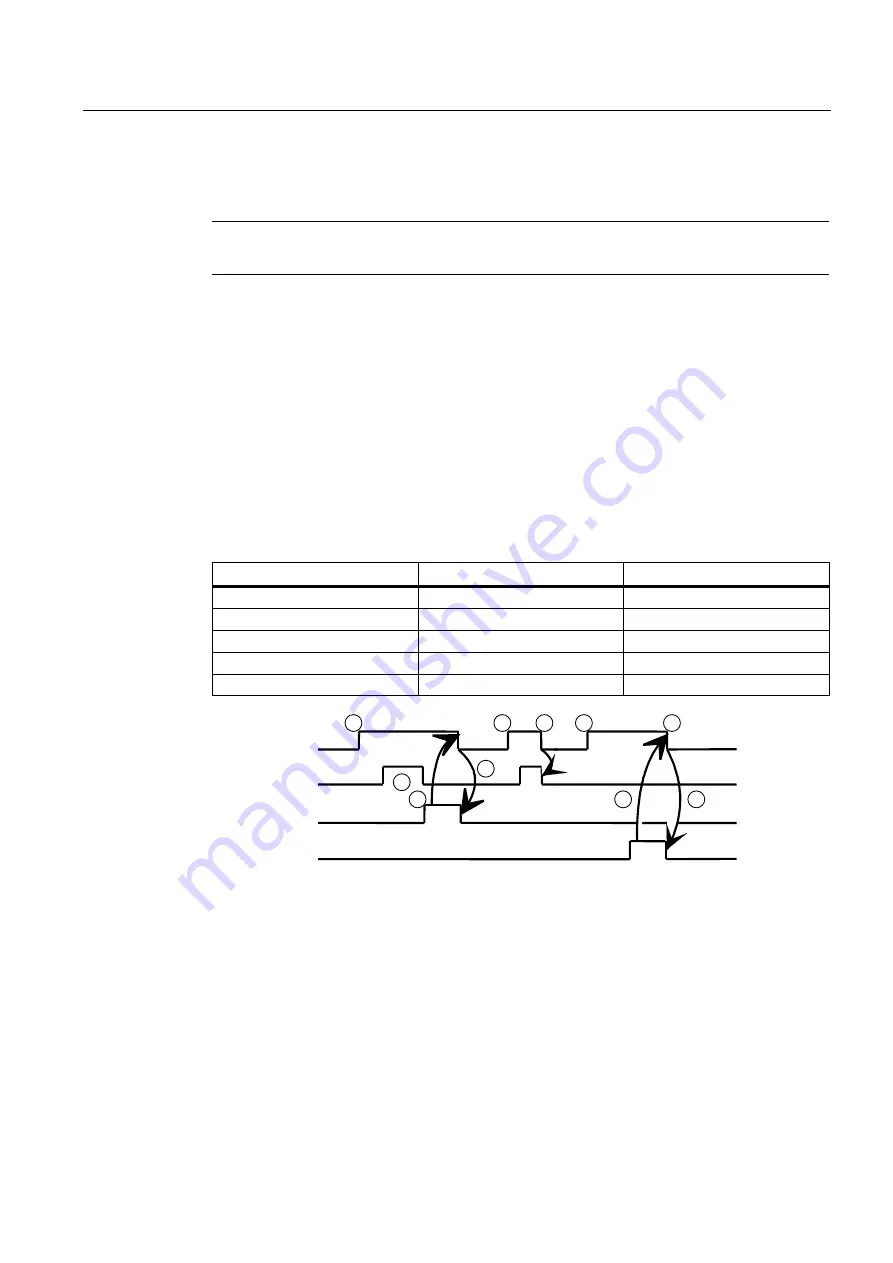

The time sequence of an ASUB is shown in the following pulse diagram in the example of

PLCASUP1_SPF. You can see from the table which interface signals are of relevance for

PLCASUP2_SPF.

Table 10- 11 Assignment of the signals to the pulse diagram

Signal

Address - PLCASUP1_SPF

Address - PLCASUP2_SPF

Start

V3400 0000.0

V3400 0001.0

Being executed

V3400 1000.1

V3400 1001.1

Completed

V3400 1000.0

V3400 1001.0

Error

V3400 1000.3

V3400 1001.3

Interrupt no. not allocated

V3400 1000.2

V3400 1001.2

6WDUW

%HLQJH[HFXWHG

&RPSOHWHG

(UURU

9

9

9

9

①

Function activation via positive edge of Start

②

ASUB is being executed

③

Positive acknowledgment: ASUB ended

④

Reset function activation after receipt of acknowledgment

⑤

Signal change through PLC

⑥

not permitted. If function activation is reset prior to receipt of acknowledgment, the output

signals are not updated without the operational sequence of the activated function being

affected

⑦

Negative acknowledgment: Error has occurred

Figure 10-3 Pulse diagram for PLCASUP1_SPF