3

SYSTEM DESCRIPTION

56

8017768/12AX/2019-05-31|SICK

O P E R A T I N G I N S T R U C T I O N S | TIC

Subject to change without notice

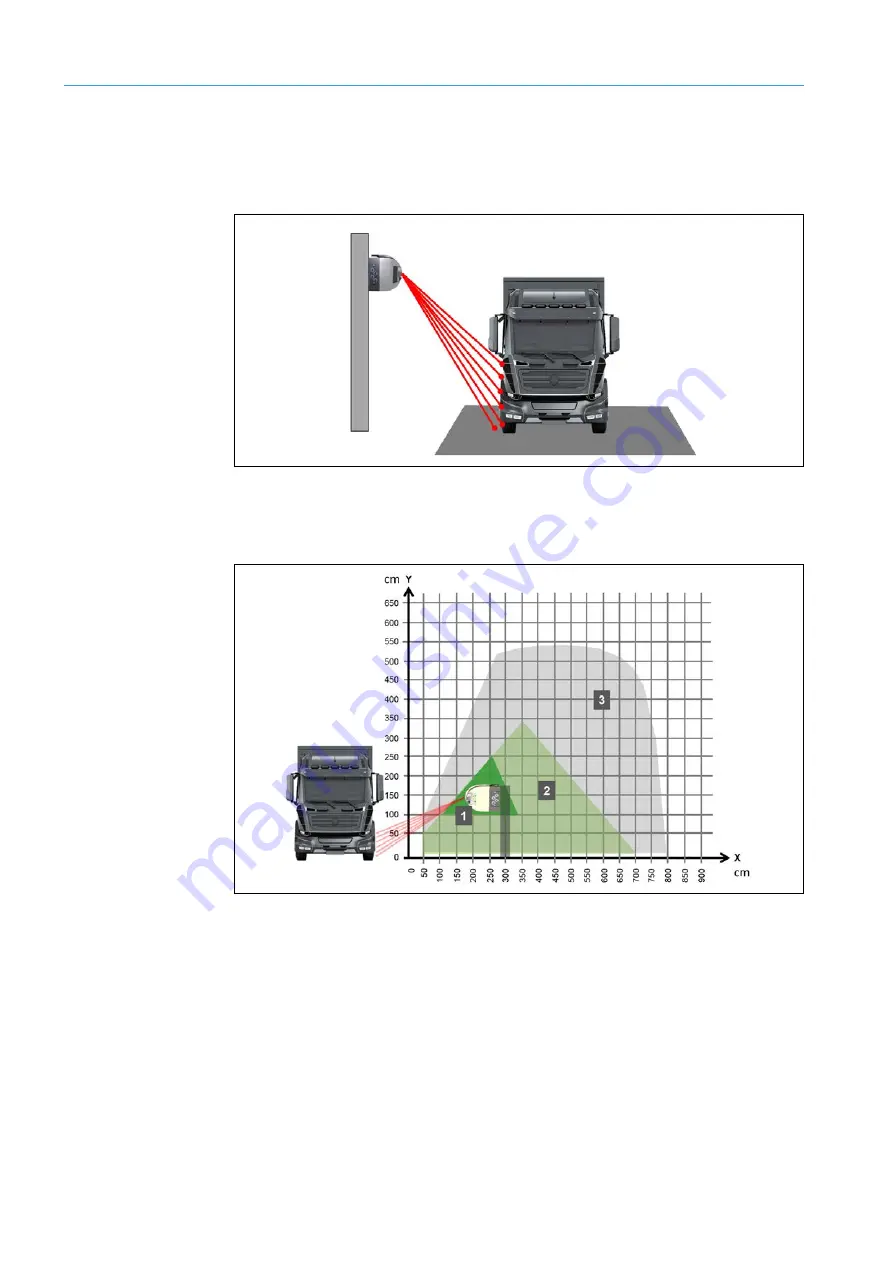

In the following figure, the mounting position is too high and, because the laser scanner

is too close to the edge of the lane, the angle of incidence is too steep. This means that

fewer measurement points are generated in the analysis area (shadow pattern, point

pattern for the wheels).

Fig. 57: Axle counting project planning – Angle of incidence for the LMS Axle (too steep)

The following figure shows the combination of the vertical and horizontal distance for the

LMS Axle that generates the best measurement results.

Fig. 58: Axle counting project planning – Ideal mounting position for the LMS Axle

The chart can be interpreted as follows:

•

The dark green triangle (1) marks the area where the LMS Axle will achieve the best

possible performance.

•

A mounting position within the light green triangle (2) will provide good to very good

results.

•

If the LMS Axle is mounted within the gray area (3), the system's ability to count axles

accurately will be reduced.