ANNEX

9

211

8017768/12AX/2019-05-31|SICK

Subject to change without notice

O P E R A T I N G I N S T R U C T I O N S | TIC

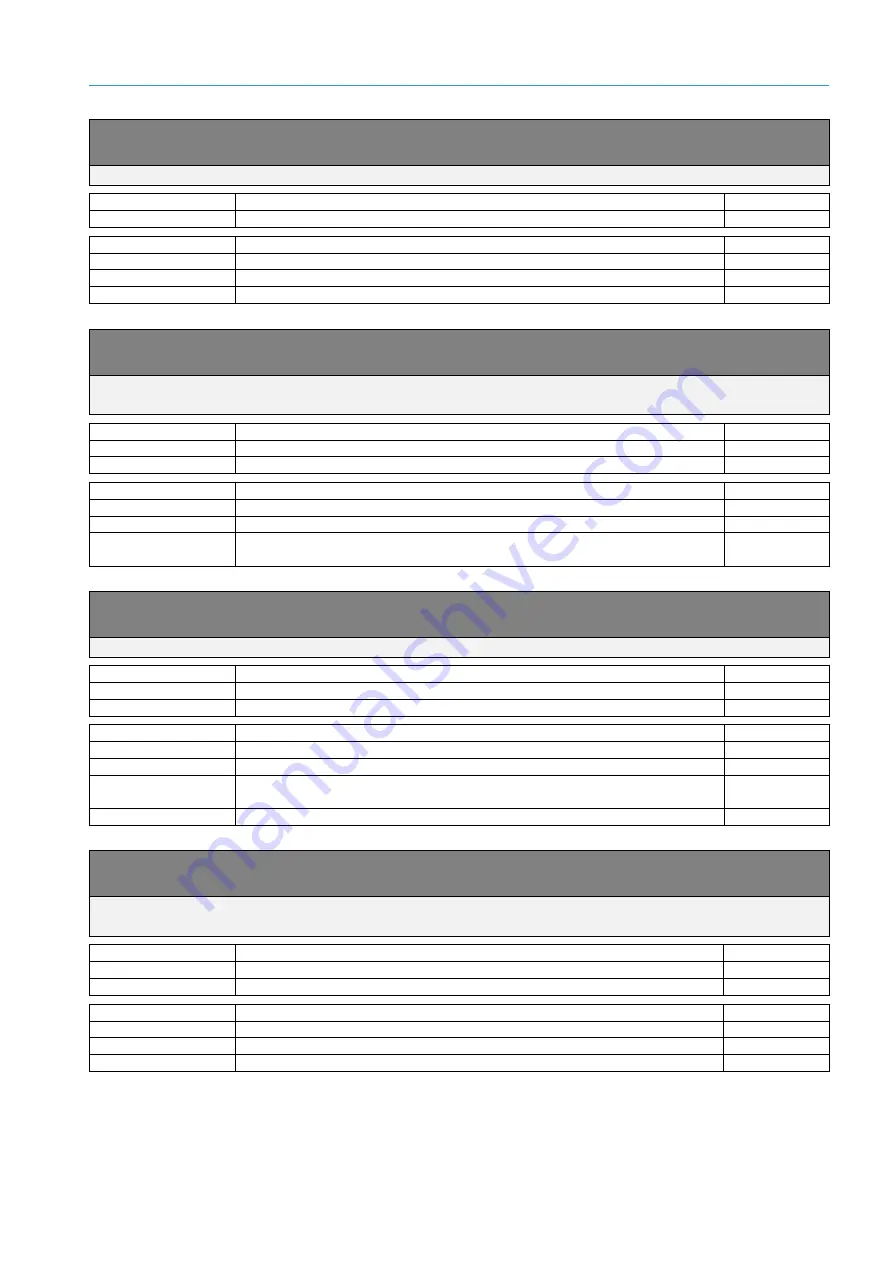

Get Current Site Configuration

Ectn.Tems.TemsManagerCmd.exe <connection info> /get=D:\Site.temsXml

Retrieves the current site configuration and serializes it to the indicated file.

Parameters

Arguments

Default

Get

Output file where the serialized site configuration is stored.

Required

Name

Description

ERRORLEVEL

Connection Failure

Timeout, network interruption, …

30

No Configuration

No configuration is currently set on the TEMS Recorder

31

Output Write Failure

Invalid output path or access denied

32

Set Site Configuration

Ectn.Tems.TemsManagerCmd.exe <connection info> /set=D:\Site.temsXml

Sets a serialized site configuration on the TEMS Recorder as the current configuration. Once this has been

successfully completed, the configuration is started as if the command line argument /start was used.

Parameters

Arguments

Default

set

File with a serialized site configuration

Required

Timeout

Number of seconds to wait for the completion of this operation

120

Name

Description

ERRORLEVEL

success

The site configuration is loaded and has state “ConfigurationRunning”

0

Input Read Failure

The site configuration file did not exist or couldn’t be accessed

40

Load Failure

TEMS Recorder rejected the site configuration for some reason. More details in the

error console.

41

Start Last Site Configuration

Ectn.Tems.TemsManagerCmd.exe <connection info> /start [ /timeout=300 ]

Restarts a site configuration that was previously stopped.

Parameters

Arguments

Default

Start

–

Required

Timeout

Number of seconds to wait for the completion of this operation

120

Name

Description

ERRORLEVEL

success

The site configuration is in state “Configuration Running”

0

Connection Failure

Timeout, network interruption, …

50

Initialization Failure

TEMS Recorder failed to initialize the configuration. More details in the error

console

51

Timeout

TEMS Recorder didn’t reach state “Not Configured” in time

52

Stop Current Site Configuration

Ectn.Tems.TemsManagerCmd.exe <connection info> /stop [ /timeout=111 ]

Stops the site configuration that is currently loaded. For example, this is required before a maintenance operation

can be started.

Parameters

Arguments

Default

Stop

–

Required

Timeout

Number of seconds to wait for the completion of this operation

60

Name

Description

ERRORLEVEL

success

The TEMS Recorder has reached (or already was) in state “No Configuration”

0

Connection Failure

Timeout, network interruption, …

60

Timeout

TEMS Recorder didn’t reach state “Not Configured” in time

61