Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

77

7

Process data

SEW Unit Profile

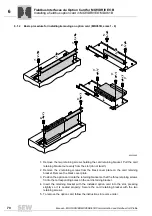

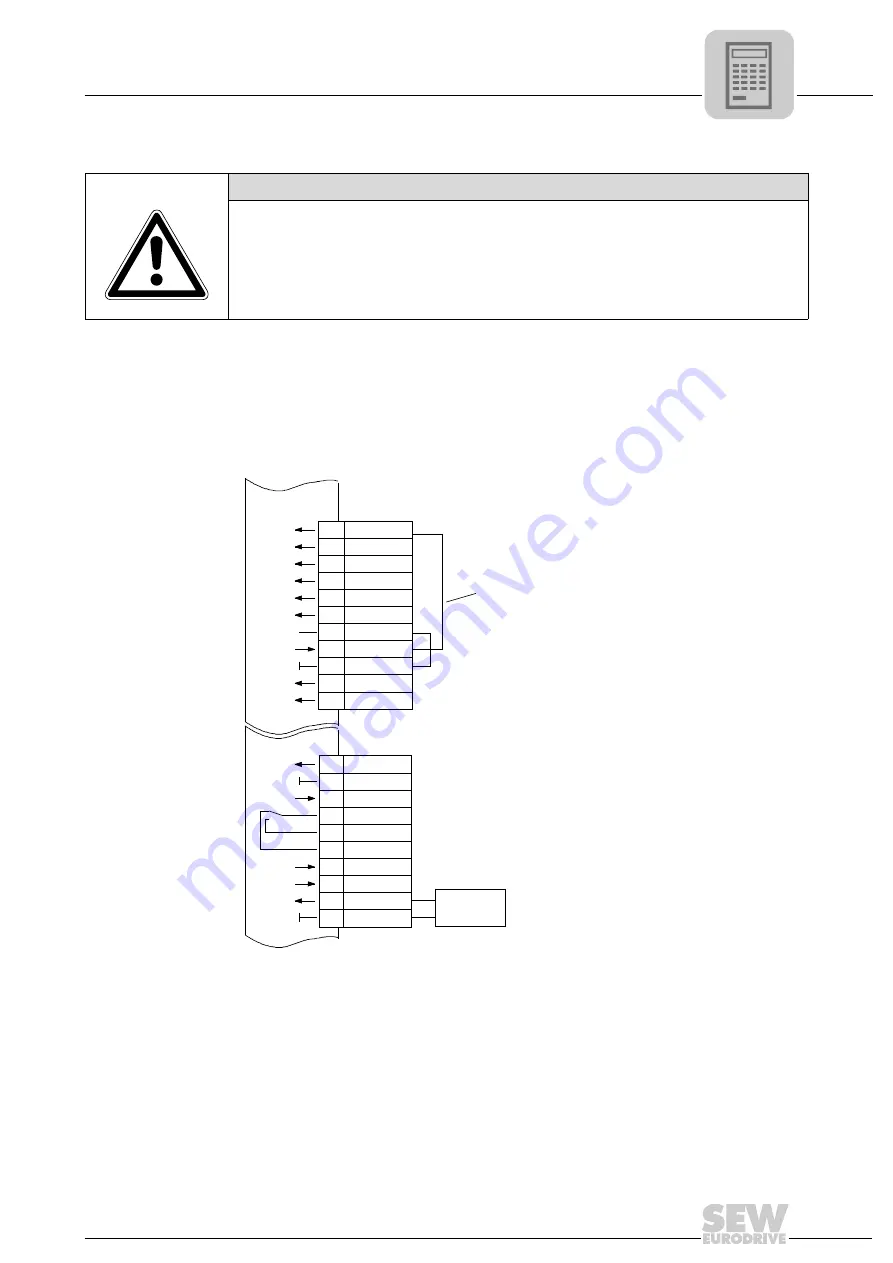

For example, the simplest way of enabling the drive inverter at the terminals is to

connect the DI00 binary input (function /

CONTROL INHIBIT

) to a +24 V signal and to

program binary inputs DI01 through DI07 to

NO FUNCTION

. The following figure gives

an example of terminal wiring and parameter setting for controlling the drive inverter

solely using process data.

NOTICE

For safety reasons, you must also

always

enable the drive inverter at the terminals for

control via process data. Consequently, you must wire or program the terminals in such

a way that the inverter is enabled via the binary inputs.

DI00 = /Controller inhibit

DI01 = no function

DI02 = no function

DI03 = no function

DI04 = no function

DI04 = no function

DI05 = no function

VO24 = + 24 V

DGND = reference potential for binary signals

ST11 = RS-485 +

ST12 = RS-485 -

TF1 = TF input

DGND = reference potential for binary signals

DB00 = /Brake

DO01-C = Relay contact

DO01-NO = Normally open contact relay

DO01-NC = Normally closed contact relay

DO02 = /Malfunction

VO24 = + 24 V

VI24 = + 24 V (external supply)

DGND = reference potential for binary signals

Enabling the power output stage using a device

jumper [1]

01234BXX

+

-

X13:

DI00

DI01

DI02

DI03

DI04

DI05

DCOM

VO24

DGND

ST11

ST12

24 V ext.

-

-

-

TF1

DGND

DB00

DO01-C

DO01-NO

DO01-NC

DO02

VO24

VI24

DGND

X10:

[1]

1

2

3

4

5

6

7

8

9

10

11

1

2

3

4

5

6

7

8

9

10

Summary of Contents for MOVIDRIVE MDX60B

Page 2: ...SEW EURODRIVE Driving the world...

Page 142: ......

Page 143: ...SEW EURODRIVE Driving the world...