Solving other problems

381

15. Troubleshooting

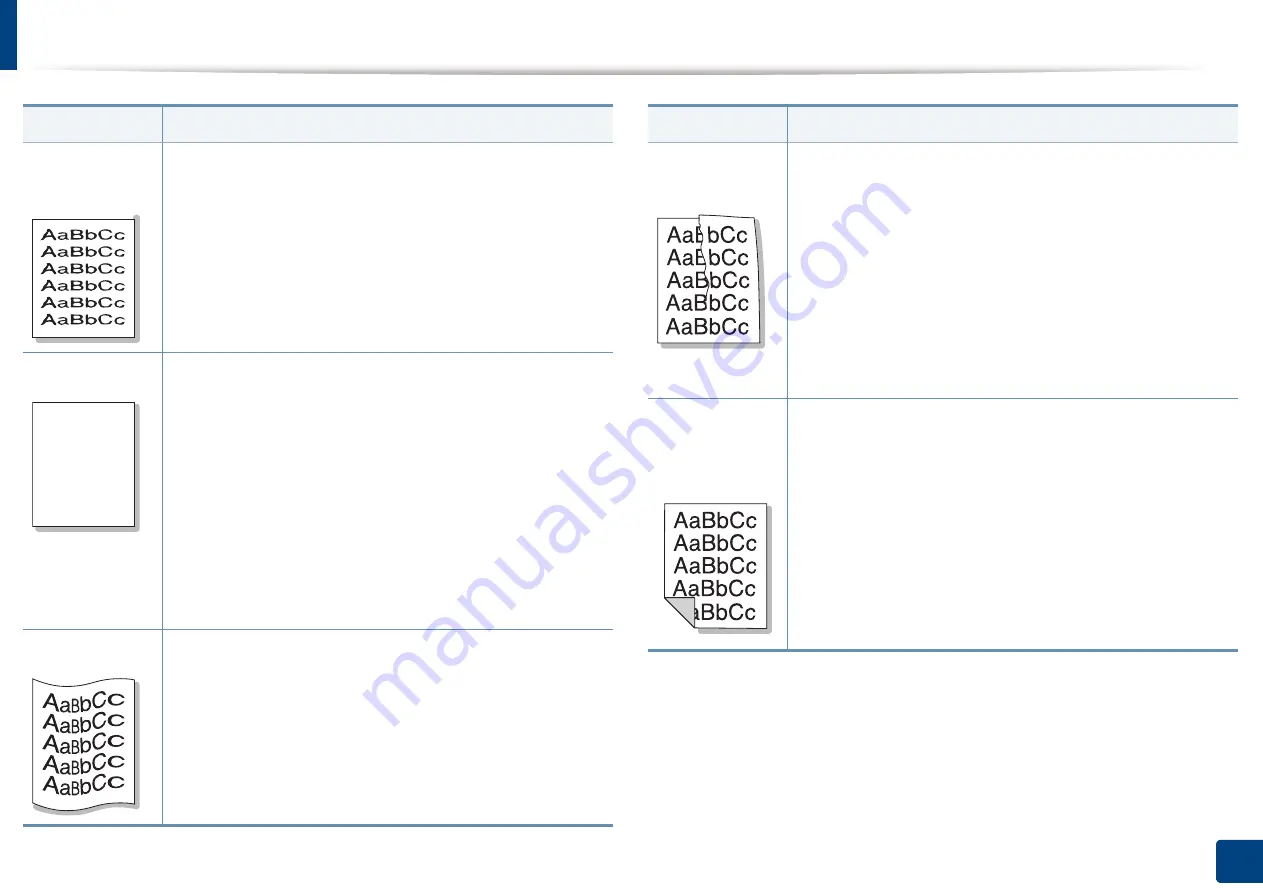

Misformed

characters

•

If characters are improperly formed and producing hollow

images, the paper stock may be too slick. Try different

paper (see "Print media specifications" on page 393).

•

If characters are improperly formed and producing a wavy

effect, the scanner unit may need service. Cleaning the

scan unit or contact a service representative.

Page skew

•

Ensure that the paper is loaded properly.

•

Check the paper type and quality (see "Print media

specifications" on page 393).

•

Ensure that the paper or other material is loaded correctly

and the guides are not too tight or too loose against the

paper stack.

•

Ensure that the standard tray right bottom door, dual

cassette feeder right bottom door or high capacity feeder

right bottom door is securely closed. If the bottom doors

are not completely closed, open and close the bottom

doors.

Curl or wave

•

Ensure that the paper is loaded properly.

•

Check the paper type and quality. Both high temperature

and humidity can cause paper curl (see "Print media

specifications" on page 393).

•

Turn the stack of paper over in the tray. Also try rotating

the paper 180° in the tray.

Condition

Suggested Solutions

A a B b C

A a B b C

A a B b C

A a B b C

A a B b C c

Wrinkles or

creases

•

Ensure that the paper is loaded properly.

•

Check the paper type and quality (see "Print media

specifications" on page 393).

•

Turn the stack of paper over in the tray. Also try rotating

the paper 180° in the tray.

•

Ensure that the standard tray right bottom door, dual

cassette feeder right bottom door or high capacity feeder

right bottom door is securely closed. If the bottom doors

are not completely closed, open and close the bottom

doors.

Back of

printouts are

dirty

Check for leaking toner. Clean the inside of the machine.

Cleaning the inside or contact a service representative.

Condition

Suggested Solutions

Summary of Contents for Multifunction MultiXpress X322 Series

Page 295: ...Redistributing toner 295 14 Maintenance 4 X322x X328x series ...

Page 296: ...Redistributing toner 296 14 Maintenance 5 K325x K330x series ...

Page 298: ...Replacing the toner cartridge 298 14 Maintenance 6 X322x X328x series ...

Page 299: ...Replacing the toner cartridge 299 14 Maintenance 7 K325x K330x series ...

Page 301: ...Replacing the imaging unit 301 14 Maintenance 8 X322x X328x series ...

Page 302: ...Replacing the imaging unit 302 14 Maintenance 9 K325x K330x series ...

Page 303: ...Replacing the imaging unit 303 14 Maintenance ...

Page 305: ...Replacing the waste toner container 305 14 Maintenance 10 X322x X328x series ...

Page 306: ...Replacing the waste toner container 306 14 Maintenance 11 K325x K330x series ...

Page 312: ...Cleaning the machine 312 14 Maintenance X322x X328x series ...

Page 313: ...Cleaning the machine 313 14 Maintenance K325x K330x series ...

Page 315: ...Cleaning the machine 315 14 Maintenance X322x X328x series ...

Page 316: ...Cleaning the machine 316 14 Maintenance ...

Page 317: ...Cleaning the machine 317 14 Maintenance K325x K330x series ...

Page 318: ...Cleaning the machine 318 14 Maintenance ...

Page 320: ...Cleaning the machine 320 14 Maintenance K325x K330x series ...

Page 324: ...Cleaning the machine 324 14 Maintenance X322x X328x series ...

Page 325: ...Cleaning the machine 325 14 Maintenance ...

Page 326: ...Cleaning the machine 326 14 Maintenance K325x K330x series ...

Page 327: ...Cleaning the machine 327 14 Maintenance ...

Page 339: ...Clearing paper jams 339 15 Troubleshooting 3 In the multi purpose tray ...

Page 341: ...Clearing paper jams 341 15 Troubleshooting Jam feed 1 Jam feed 2 ...

Page 342: ...Clearing paper jams 342 15 Troubleshooting Jam feed 3 Jam feed 4 Optional device only ...

Page 357: ...Clearing paper jams 357 15 Troubleshooting 8 In the optional finisher area ...