Confidential & Proprietary|© ROKIT Healthcare Inc. 2019. All Rights Reserved

Dr. INVIVO 4D User Guide

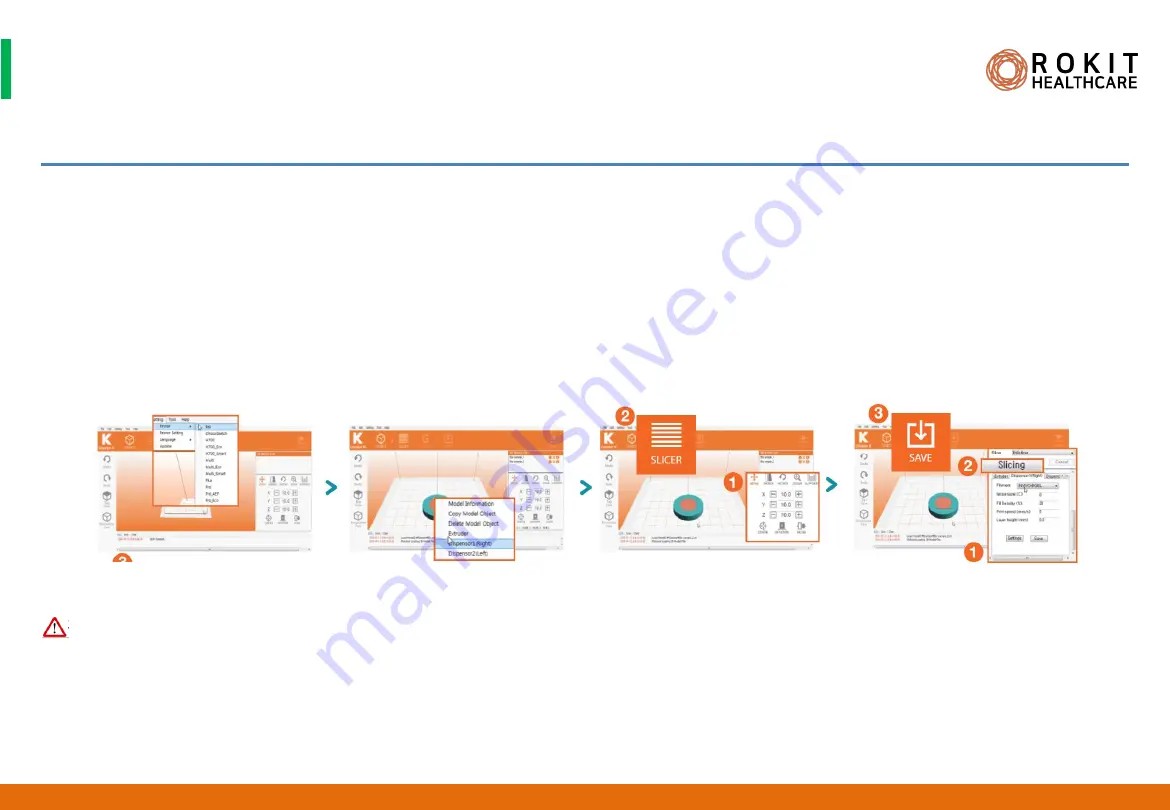

Creating a G-Code for Dual Printing

1. Run [New Creator K] installed on your PC.

2. Select [Settings]> [Printer]> [Bio] on the top menu of NewCreatorK.

3. Press [File]> [Open] to load two 3D model files.

4. Right-click on each object and select the desired dispenser type.

5. In [OBJECT], you can individually move and rotate, set the dimensions of each file. Press the [Ctrl] key to do it with the both file

simultaneously.

6. In [SLICER], enter the printing setting parameters (output speed, output nozzle temperature, fill%, etc.).

7. Click the [Slicing] button at the top to create a G-Code file, and then click the [SAVE] button to save the file.

1. The right Dispenser is Dispenser1 and the left Dispenser is Dispenser2.

37

INV-CHS-20191210

CAUTION