Wrist Camera - Instruction Manual

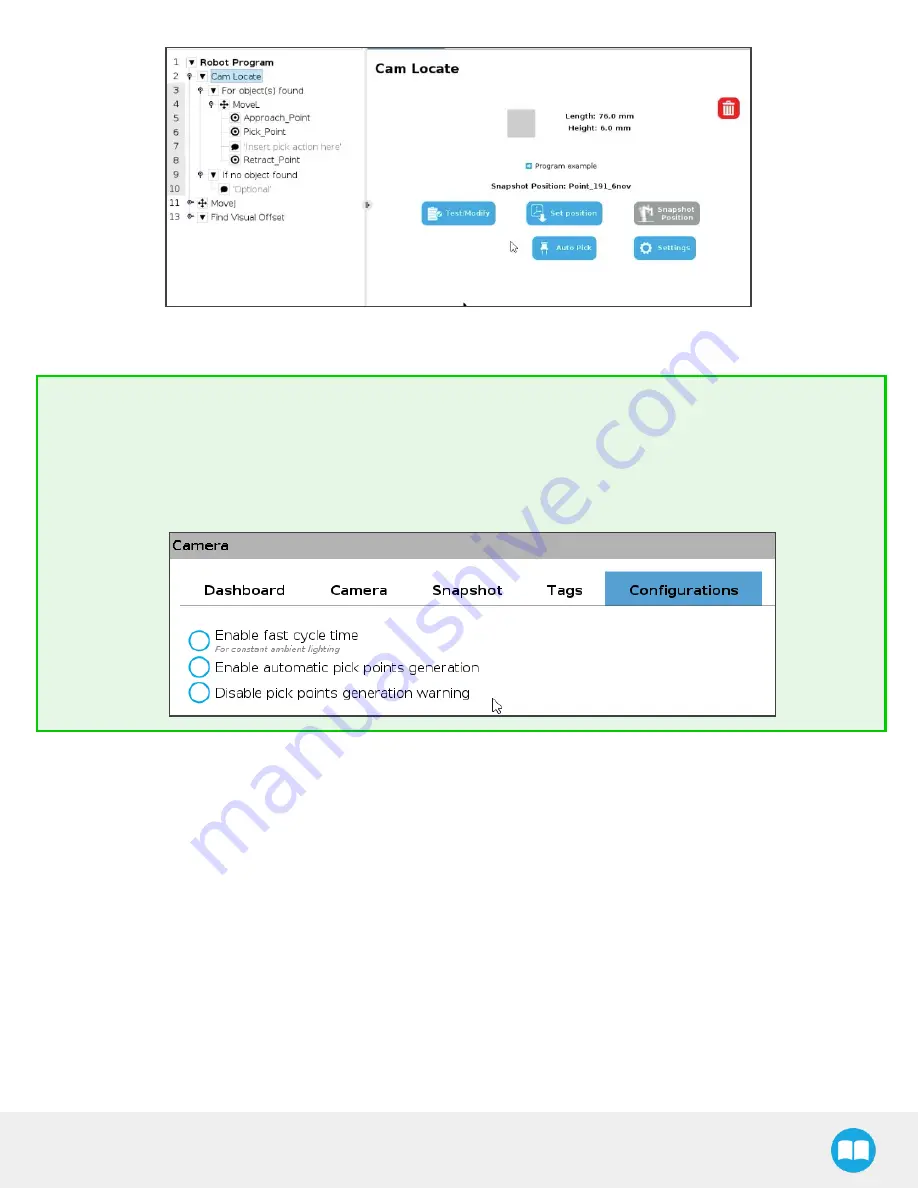

Fig. 4-77: This MoveL node was inserted using the Auto Pick button.

Tip

For a smoother experience using Auto Pick, modify teach pendant options under Installation > URCaps > Camera

> Configurations. Check the following radio buttons:

l

" Enable automatic pick points generation"

l

" Disable pick points generation warning"