2.

Remove the mounting screw.

If the mounting screw is attached to the adjusting screw hole, unfasten it.

3.

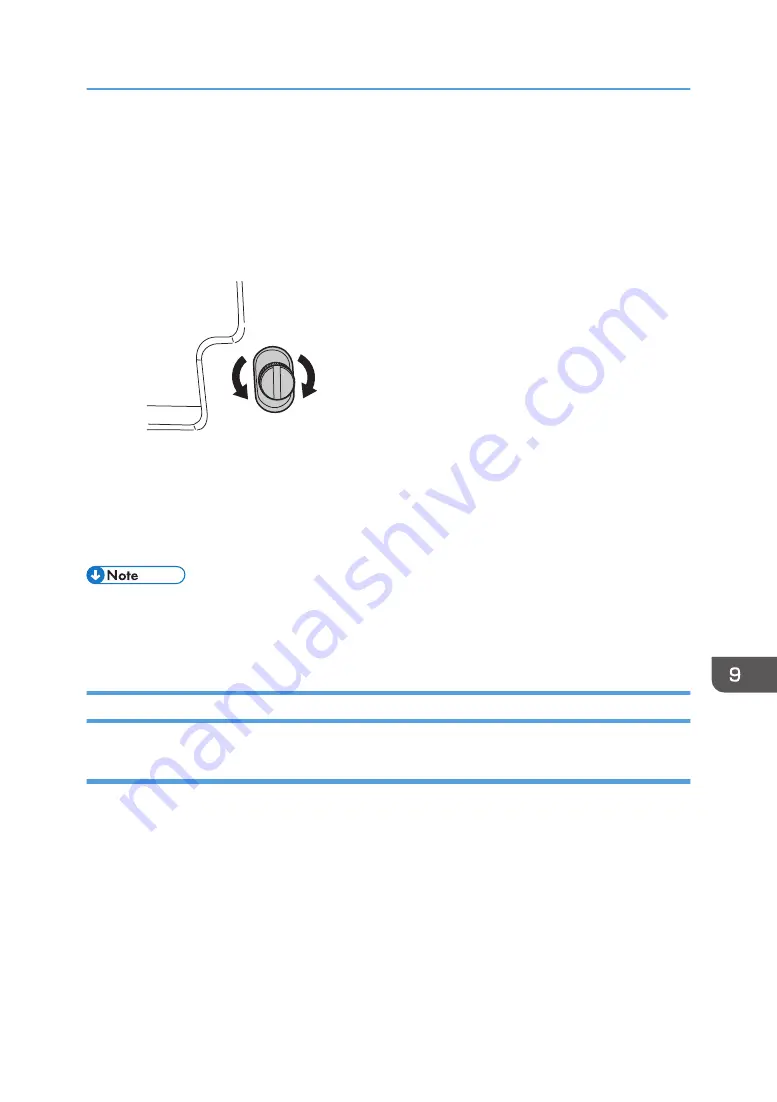

Turn the adjusting screw to adjust the deviation.

• To increase the length at the bottom part of paper, turn the screw clockwise.

• To decrease the length at the bottom part of paper, turn the screw counterclockwise.

CEZ510

4.

Attach the mounting screw to fasten the adjusting screw.

If the mounting screw is attached to the adjusting screw hole, fasten it.

5.

Close the front cover of the multi-folding unit.

• For multi-sheet folding, the folding deviation that appears in the center of paper will be adjusted.

• If the deviation is large, the paper may be skewed. For further information, see page 91 "Paper

Folds Stained by Multi-sheet Folding

Cause:

If multi-sheet folding is performed after a large number of Z-folds have been performed, the tip of the

blade used for the multi-sheet folding may be stained, resulting in stained paper.

Multi-Folding Unit

143

Summary of Contents for TCRU/ORU

Page 2: ......

Page 10: ...8...

Page 18: ...1 Before You Begin 16...

Page 20: ...2 Troubleshooting Service Call Problems SC Codes 18...

Page 60: ...6 Image Quality Problem Spots 58...

Page 84: ...7 Image Quality Problem Full Page 82...

Page 132: ...8 Troubleshooting Paper Delivery Problems 130...

Page 160: ...9 Post Processing Option Troubleshooting 158...

Page 183: ......

Page 184: ...EN GB EN US EN AU D0AK 7433 2018...