1.1.9

Top Cover

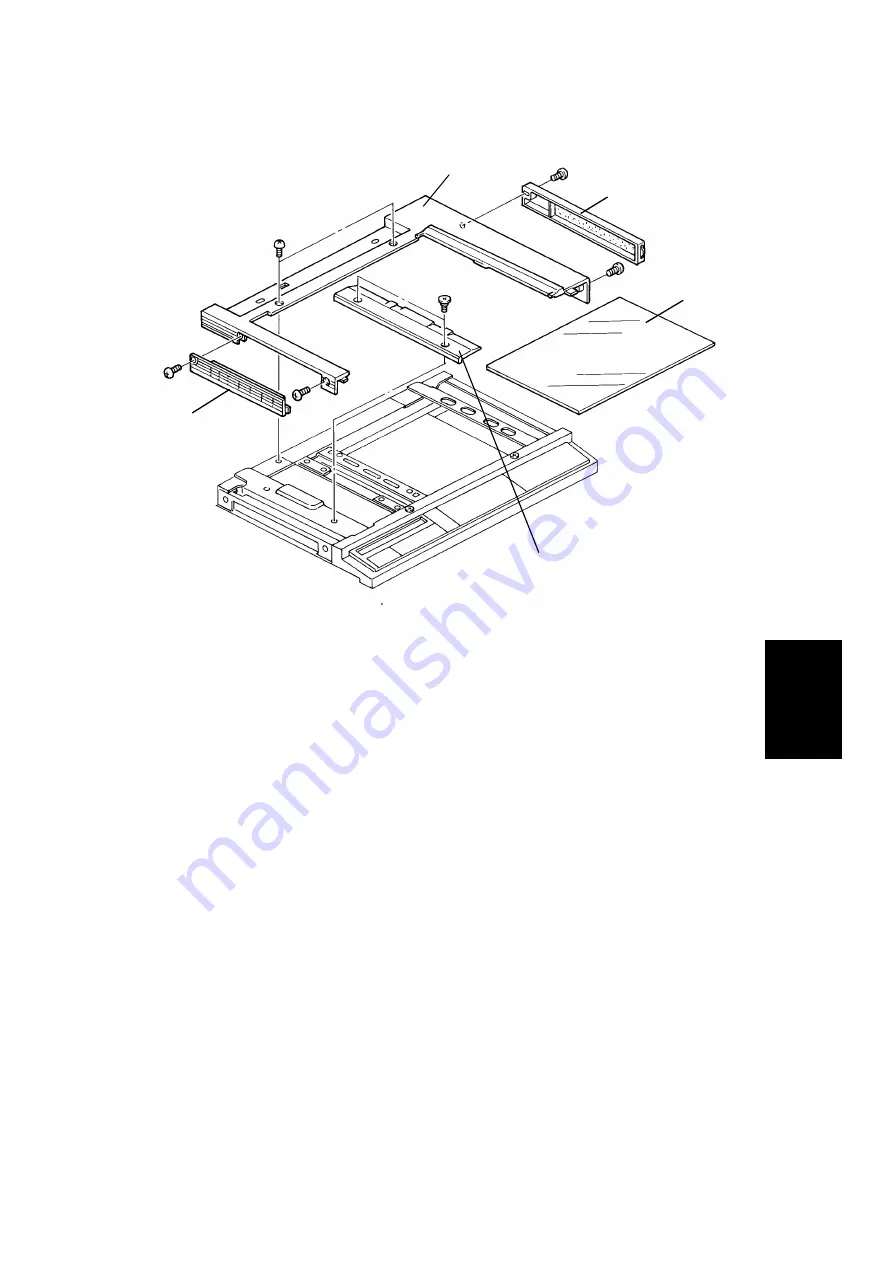

NOTE: Remove the document feeder or platen cover if either is installed.

1. Remove the left scale [A] (2 shoulder screws).

2. Remove the exposure glass [B].

3. Remove the right and left optics covers [C, D] ( 1 screw each).

4. Remove the top cover [E] (4 screws).

[E]

[C]

[B]

[A]

[D]

Replacem

ent

Adjustm

ent

12 February 1992

EXTERIOR AND INNER COVERS

5-5

Summary of Contents for A085

Page 3: ...FT4227 FT4427 FT4727 A085 A087 A088 ...

Page 6: ...3 LOCATION OF UNIT ...

Page 7: ...4 LOCATION OF UNIT ...

Page 8: ...5 LOCATION OF UNIT ...

Page 9: ...6 LOCATION OF UNIT ...

Page 10: ...7 LOCATION OF UNIT ...

Page 11: ...8 LOCATION OF UNIT ...

Page 12: ...9 LOCATION OF UNIT ...

Page 13: ...10 1 EXTERIOR 1 A085 A087 A088 ...

Page 15: ...12 2 EXTERIOR 2 A085 A087 A088 ...

Page 17: ...14 3 OPERATION PANEL A085 A087 A088 ...

Page 19: ...16 4 PLATEN COVER A085 A087 A088 ...

Page 21: ...18 5 OPTICS SECTION 1 A085 A087 A088 ...

Page 23: ...20 6 OPTICS SECTION 2 A085 A087 A088 ...

Page 25: ...22 7 OPTICS SECTION 3 A085 A087 A088 ...

Page 27: ...24 8 OPTICS SECTION 4 A085 A087 A088 ...

Page 29: ...26 9 OPTICS SECTION 5 A085 A087 A088 ...

Page 31: ...28 10 BY PASS FEED TABLE A085 A087 A088 ...

Page 33: ...30 11 PAPER FEED TRAY A085 A087 A088 ...

Page 35: ...32 12 PAPER FEED SECTION A085 A087 A088 ...

Page 37: ...34 13 TRAY LIFT SECTION A085 A087 A088 ...

Page 39: ...36 14 LCT SECTION 1 A087 A088 ...

Page 41: ...38 15 LCT SECTION 2 A087 A088 ...

Page 43: ...40 16 LCT SECTION 3 A087 A088 ...

Page 45: ...42 17 VERTICAL TRANSPORT SECTION A085 A087 A088 ...

Page 47: ...44 18 PAPER REGISTRATION A085 A087 A088 ...

Page 49: ...46 19 DRUM SECTION 1 A085 A087 A088 ...

Page 51: ...48 20 DRUM SECTION 2 A085 A087 A088 ...

Page 53: ...50 21 DEVELOPMENT UNIT 1 A085 A087 A088 ...

Page 55: ...52 22 DEVELOPMENT UNIT 2 A085 A087 A088 ...

Page 57: ...54 23 CLEANING UNIT A085 A087 A088 ...

Page 59: ...56 24 T S CORONA UNIT A085 A087 A088 ...

Page 61: ...58 25 TRANSPORT SECTION A085 A087 A088 ...

Page 63: ...60 26 FUSING UNIT 1 A085 A087 A088 ...

Page 65: ...62 27 FUSING UNIT 2 A085 A087 A088 ...

Page 67: ...64 28 PAPER EXIT SECTION 1 A085 A087 A088 ...

Page 69: ...66 29 PAPER EXIT SECTION 2 A085 A087 A088 ...

Page 71: ...68 30 FRAME SECTION 1 A085 A087 A088 ...

Page 73: ...70 31 FRAME SECTION 2 A085 A087 A088 ...

Page 75: ...72 32 FRAME SECTION 3 A085 A087 A088 ...

Page 77: ...74 33 FRAME SECTION 4 A085 A087 A088 ...

Page 79: ...76 34 DRIVE SECTION 1 A085 A087 A088 ...

Page 81: ...78 35 DRIVE SECTION 2 A085 A087 A088 ...

Page 83: ...80 36 ELECTRICAL SECTION 1 A085 A087 A088 ...

Page 85: ...82 37 ELECTRICAL SECTION 2 A085 A087 A088 ...

Page 87: ...84 38 ELECTRICAL SECTION 3 A085 A087 A088 ...

Page 89: ...86 39 ELECTRICAL SECTION 4 A085 A087 A088 ...

Page 91: ...88 40 DUPLEX UNIT 1 A088 ...

Page 93: ...90 41 DUPLEX UNIT 2 A088 ...

Page 95: ...92 42 DUPLEX UNIT 3 A088 ...

Page 97: ...94 43 MAIN CONTROL BOARD A085 A087 A088 ...

Page 98: ...95 43 MAIN CONTROL BOARD A085 A087 A088 ...

Page 99: ...96 43 MAIN CONTROL BOARD A085 A087 A088 ...

Page 102: ...99 44 MEMORY BOARD A085 A087 A088 ...

Page 104: ...101 45 AC HARNESS A085 A087 A088 ...

Page 106: ...103 46 DC HARNESS TYPE 2 A085 A087 A088 ...

Page 108: ...105 47 DC HARNESS TYPE 4 A085 A087 A088 ...

Page 110: ...107 48 FUSING UNIT HARNESS A085 A087 A088 ...

Page 112: ...109 49 LCT HARNESS A087 A088 ...

Page 114: ...111 50 DECAL AND DOCUMENT A085 A087 A088 ...

Page 115: ...112 50 DECAL AND DOCUMENT A085 A087 A088 ...

Page 116: ...113 50 DECAL AND DOCUMENT A085 A087 A088 ...

Page 117: ...114 50 DECAL AND DOCUMENT A085 A087 A088 ...

Page 118: ...115 50 DECAL AND DOCUMENT A085 A087 A088 ...

Page 120: ...117 51 SPECIAL TOOL A085 A087 A088 ...

Page 122: ...PARTS INDEX ...

Page 154: ...SECTION 1 OVERALL MACHINE INFORMATION ...

Page 163: ...SECTION 2 DETAILED SECTION DESCRIPTION ...

Page 165: ...SECTION 3 INSTALLATION ...

Page 178: ...SECTION 4 SERVICE TABLES ...

Page 201: ...SECTION 5 REPLACEMENT AND ADJUSTMENT ...

Page 227: ...FT5233 5433 5733 SERVICE MANUAL ...

Page 230: ...SECTION 1 OVERALL MACHINE INFORMATION ...

Page 255: ...SECTION 2 DETAILED SECTION DESCRIPTIONS ...

Page 373: ...SECTION 3 INSTALLATION ...

Page 403: ...SECTION 4 SERVICE TABLES ...

Page 449: ... 6 Duplex Tray PREVENTIVE MAINTENANCE SCHEDULE 12 February 1992 4 46 ...

Page 456: ...SECTION 5 REPLACEMENT AND ADJUSTMENT ...

Page 575: ...SECTION 6 TROUBLESHOOTING ...