IMAGE FUSING AND PAPER EXIT

20 June 2005

6-92

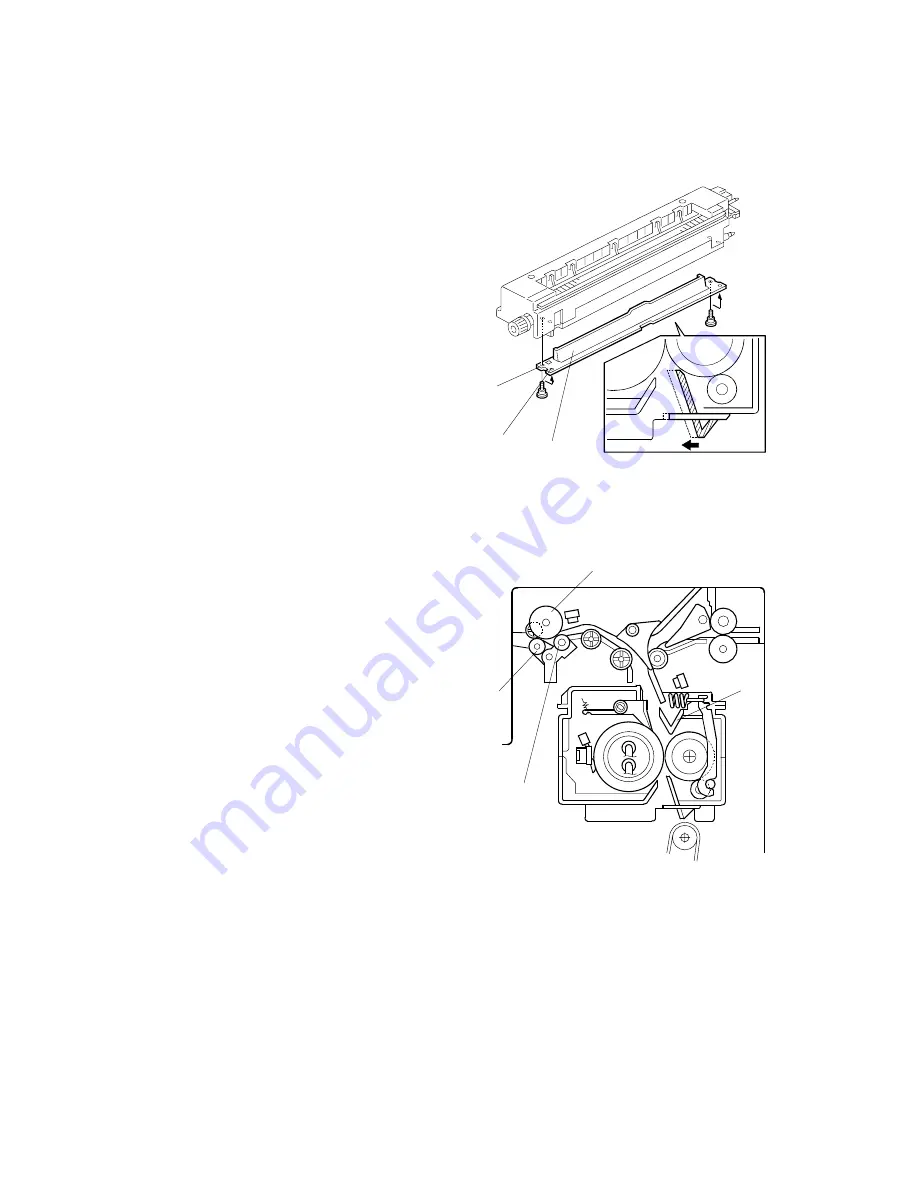

6.15.4 FUSING ENTRANCE GUIDE SHIFT MECHANISM

The entrance guide [A] has two holes on

each side to adjust for paper thickness to

prevent creasing. Normally, the left screw

hole [C] on each side is used.

For

thin

paper, use screw holes [B] to

move the entrance guide to the left. This

setting allows more direct access to the

gap between the hot and pressure rollers,

and prevents thin paper from buckling

against the hot roller which can cause

blurring at the leading edge of the copy.

6.15.5 EXIT GUIDE PLATE AND DE-CURLER ROLLERS

The exit guide plate [A] also functions as a

pressure roller stripper. The exit guide

plate can be moved in order to remove

jammed paper.

Stacking has been improved by mounting

a face-curl correction mechanism at the

paper exit roller.

Two de-curler rollers [B] and [C] have been

added under the exit roller [D] to correct

the curl that paper acquires during

transport through the fusing unit.

B195D979.WMF

B195D980.WMF

[A]

[B]

[C]

[C]

[D]

[B]

[A]