DEVELOPMENT

20 June 2005

6-62

6.9.4 DEVELOPMENT BIAS

Mechanism

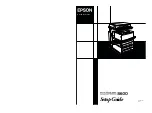

Black areas of the latent image are at a

low negative charge (about –150 V) and

white areas are at a high negative charge

(about –850 V).

To attract negatively charged toner to the

black areas of the latent image on the

drum, the high voltage supply board [A]

applies a bias of –560 volts to the

development roller throughout the image

development process. The bias is applied

to the development roller shaft [B]

through the bias terminal spring [C] and

bias terminal [D].

The development bias voltage (-560 V) can be adjusted with SP2-201

(Development Bias).

Correction for paper width and thickness (by-pass tray only)

The by-pass tray can be used for non-standard paper narrow than sizes accepted

by the paper trays. Thicker paper, OHP sheets, etc. can also be loaded in the by-

pass tray but adjustments must be performed with the SP modes listed below in

order to avoid jams and misfeeds.

SP Mode

SP Name

SP2201 1

Development Bias

Width 216 - 297 mm (Default: -560V)

SP2309 1

Paper Lower Width [a]

Width limit (Default: 150 mm)

SP2309 2

Paper Upper Width [b]

Width limit (Default: 216 mm)

SP2914 3

Process Control Setting (B

γ

)

Adjust 10V/step (Default: 200V)

SP2914 4

Process Control Setting (B

δ

)

Adjust 10V/step (Default: 50V)

The way that these SP modes are used is shown below.

For example, with the default settings, if the paper width fed from the by-pass tray

is 200 mm, the development bias voltage will be –560 + 50 V.

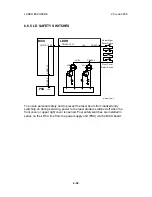

B195D942.WMF

0 mm

SP 2309 1

Default: 150 mm

SP 2309 2

Default: 216 mm

297 mm

Voltage:

SP2201 1 + SP2914 3

Default: -560 + 200 V

Voltage:

SP2201 1 + SP2914 4

Default: -560 + 50 V

Voltage:

SP2201 1

Default: -560 V

B195D915.WMF

[A]

[B]

[C]

[D]