1.800.627.4499

30

Integral Indirect Gas-Fired Heat Module

OPTION

5.0 INSTALLATION

5.1 MODULE INSPECTION ON ARRIVAL

This module was test operated and inspected at the factory prior to shipment and was

in satisfactory working order. A copy of the test and inspection sheet is included in the

documentation package provided. Inspect the packaging on delivery for any signs of damage.

Report any damage immediately to the transporting agency.

5.2 PREPARING FOR INSTALLATION

The type of gas for which the module is equipped, the input rating and electrical ratings are all

shown on the unit data plate, found on the outside of the unit. Before installation, be sure that

the available gas and electrical supply match the unit data plate information.

Read this manual in its entirety before beginning installation. Check with local gas utility or

agencies having jurisdiction to determine if there are local requirements covering installation of

heat modules.

5.3 INSTALLATION CODES

The heat module covered in this manual is design certified by Intertek Testing Services/ETL for

commercial or industrial use in the United States and Canada.

These units must be installed in accordance with local building codes, the National Fuel

Gas Code (NFPA54/ANSI Z223.1 or in Canada, with the Canadian Natural Gas and Propane

Installation Code (CSA B149.1)

5.4 PLACEMENT OF MODULE

The module is factory-installed in a DOAS manufactured by RenewAire. It is the installing

contractor's responsibility to verify that installation of the DOAS with its gas heat module is

installed safely, in accordance with all applicable codes.

5.5 CLEARANCES

Clearances are as detailed on the Dimensioned Drawing of each unit type, as applicable.

Dimensioned drawings are to be found in the DN-Series IOM.

Sufficient space must be left in front of the DOAS to allow for servicing of the unit and its gas

heater module. This space will normally be equal to the width of the access door to the energy

recovery module. This also allows for adequate clearance for intake air for units that do not

utilize two-pipe separated combustion systems. See the dimensioned drawing for each model,

as applicable.

All gas heat modules must be connected to a venting system to convey flue gases outside of the

heated space.

Vent locations for vertically vented units:

Exhaust vent cap must be a minimum of 2 feet above the highest point on the roof. Provide

sufficient clearance to exceed anticipated snow depth.

Vent locations for horizontally vented units:

Exhaust vent cap must be a minimum of 1 foot from the exterior wall and 3 feet above the

anticipated snow depth. The terminal must be installed with a minimum horizontal clearance of

4 feet from electric meters, gas meters, regulators or relief equipment.

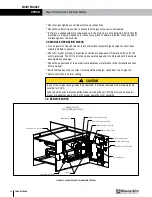

IMPORTANT

Provide adequate service access for maintenance. The module requires regular inspections.

Install the module where the access panels can be removed for cleaning and inspection and

wiring can be accessed for installation and service. Observe all safety precautions when

working on roofs, including locating the unit away from roof edges, provision of safety rail-

ings and use of fall-protection equipment.

INSTALLATION