1.800.627.4499

8

Integral Indirect Gas-Fired Heat Module

OPTION

1.5 GAS MODULE MODULATION (TURNDOWN)

Turndown is a gas module operating mode in which the input gas volume is reduced to provide

more consistent heating of the Occupied Space. Example: a 200 MBH input module is being

used to provide heat when ambient conditions call for only a small amount of added heat.

Rather than the module running at full output for a brief period, the gas supply is reduced in

order to provide a smaller heat output, which allows the module to run for a longer period,

improving hysteresis. Each modulation scheme requires that the gas train be designed for

that specific turndown scheme. Modulation of the gas supply typically involves a different gas

valve or valves, some programming differences to the onboard controller and a different gas

manifold. All heat modules are modulated. RenewAire gas heat modules are available with the

following turndown options:

u

5:1 Modulation (available for gas heat modules 50–350 MBH)

u

10:1 Modulation (available for gas heat modules 200–350 MBH)

Module turndown is expressed as a ratio of the maximum to minimum heat output. Example: a

module that can deliver as little as one tenth of its maximum rating is said to have a turndown

ratio of 10:1.

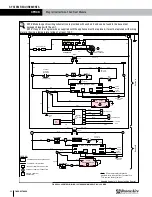

1.6 GAS VALVES

Gas valves used in RenewAire gas heat modules are 1-stage, 2-stage and modulated. See

Section 4.7 Gas Valve Illustrations in this manual. Every gas valve is normally closed (NC) and

requires an activating signal from an ignition controller to activate the valve solenoid. If the

valve is 2-stage, an additional signal from the signal conditioner is required to change the

gas output to the second level, or stage. If the valve is modulating, a variable (analog) signal

is required from the signal conditioner to vary the gas output from the valve. Staged valves

(either 1-stage or 2-stage) have fixed output levels for each stage. A modulating valve provides

a variable output, dependent on a 0–10 volt signal sent to the valve from the Maxitrol Signal

Conditioner. Modulating valves are used in conjunction with staged valves to arrive at the

desired turndown.

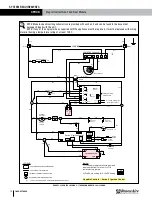

1.7 IGNITION CONTROLLERS

Each gas manifold or each section of a split manifold has its own ignition system, controlled

by a Capable Controls Series 5 ignition controller. The ignition controller controls the ignition

spark, the flame sensor, air proving switch and activates the solenoid on the gas valve.

Heat modules with 5:1 turndown generally have only one ignition controller and a single gas

manifold. Heat modules with 10:1 turndown generally have a split gas manifold with two ignition

controllers and two ignition systems.

FIGURE 1.7.0 IGNITION CONTROLLER (TYPICAL)

FIGURE 1.7.1 MAXITROL SC-30 SIGNAL CONDITIONER

MODEL SC-30 USED TO ACHIEVE 10:1 TURNDOWN IN 3-VALVE SCHEMES

MODEL SC-40 USED TO ACHIEVE 5:1 TURNDOWN IN 2-VALVE SCHEMES

OVERVIEW