1.800.627.4499

34

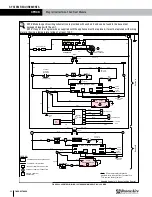

Integral Indirect Gas-Fired Heat Module

OPTION

4.00

2.00

DETAIL A

SCALE 1 : 8

PLUG

TEE FITTING

STAINLESS STEEL

TRAP LINE

RenewAire LLC

SCALE:1:24

SIZE

DWG. NO.

A

MATERIAL:

FINISH:

SEE BILL OF MATERIAL

DO NOT SCALE DRAWING.

REMOVE ALL BURRS, BREAK

SHARP EDGES.

APPLICABLE STANDARDS: DIM.

AND TOL. ANSI Y14.5

UNLESS OTHERWISE SPECIFIED,

DIMENSIONS ARE IN INCHES.

TOLERANCES:

LINEAR 0.015

HOLE SIZE 0.005

ANGULARITY 3

SURFACE FINISH =

63 MICROINCH MINIMUM

DATE:

DRAWN BY:

CAH

10/29/18

DN RT GH

Draintrap OCT18

SHEET 1 OF 1

201 Raemisch Rd.

Waunakee, WI 53597 USA

TEL: (608) 221-4499

FAX: (608) 221-2824

TOLL FREE: (800) 627-4499

TITLE:

CHECKED BY:

DATE:

--

--

DN-3-RT GH CONDENSATE DRAIN

LEVEL DESCRIPTION OF REVISION

DATE

BY

-

-

-

-

-

SEE BILL OF MATERIAL

A manual shut-off valve (gas cock), a 1/8 inch plugged test port or bleeder valve and a drip leg

must be field-installed between the gas supply pipe and the start of the gas train. The valve and

test port must be accessible for the connection of a test gauge. Supply gas connections must

be made by a qualified installer and are to be provided by others.

Connect gas supply piping to the gas fitting on the front of the module. Follow all local codes,

or, in the absence of any local codes, comply with ANSI Z223.1.

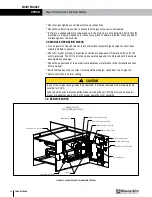

5.9 CONNECT CONDENSATE DRAIN

Each ducted gas module is equipped with a 3/8 inch diameter stainless steel condensate drain

tube that extends from the front of the module. The condensate drain tube is under negative

pressure and must be trapped. The trap is to be provided by others and field-installed. The trap

should be fabricated in accordance with local building codes. It should allow for easy cleaning

and easy addition of a glycol solution, if needed for winterization. In addition, attention should

be given to the possible need for heat tapes. If heat tapes are to be used, it may be necessary

to fabricate the trap and other drain piping from metal.

The drain trap should be filled with water or glycol solution prior to module start-up.

OPERATION

FIGURE 5.9.0 RECOMMENDED DRAIN TRAP CONSTRUCTION

6.0 OPERATION

6.1 GAS HEATER QUICK-START GUIDE

A wiring diagram and a Sequence of Operation are provided in the unit information package

for each specific control system provided on the heat module. Refer to the documents before

attempting to place the unit in service.

u

This heat module does not have a pilot light. It is equipped with a direct spark ignition device

that automatically lights the gas burner. DO NOT try to light burners by hand.

u

BEFORE OPERATING, leak test all gas piping up to the heater valve. Smell around the unit

area for gas. DO NOT attempt to place the unit in operation until source of gas leak is

identified and corrected.

u

Use only hand force to push and turn the gas control knob to the “ON” position. NEVER use

tools. If knob does not operate by hand, replace gas valve prior to starting the unit. Forcing or

attempting to repair the gas valve may result in fire or explosion.

u

Do not attempt to operate the module if there is indication that any part or control has been

under water. Any control or component that has been under water must be replaced prior to

trying to start the module.

The gas heat module requires both high-voltage power and a low-voltage control signal. High-

voltage power is present whenever the DN-Series disconnect switch is turned on. The control

signal is provided by the DN-Series Integrated Programmable Controller.

NOTE: Start-Up

is defined as the

process of activating

each system within a new-

ly-installed module after it

has been properly installed

in the system in which it is

expected to operate. A full

and proper start-up cannot

be performed unless the

Occupied Space with all its

associated ductwork, con-

trols and design options

are completed and intact

and ready for full-load

testing.