37

1.800.627.4499

Integral Indirect Gas-Fired Heat Module

OPTION

6.2.5 Verify That Heater Settings Will Call For Heat

Go to the Unit Status > Heating screen.

Current

Temperature

SETPOINT

(MUST BE GREATER THAN

CURRENT TEMPERATURE)

COMMAND

(SHOWS THE STRENGTH OF THE

CALL FOR HEAT SIGNAL AS A

PERCENTAGE OF 10 VDC)

Unit Status

Setpoint

79.00 F

78.60 F

Command

100.0

0

%

HEATING

Output ON

YES

Disabled

NO

u

The “Current Temperature” should be lower than the “Setpoint”. If the Setpoint is lower

than the Current Temperature, the controller will not call for heat. Change the setpoint, if

necessary.

u

The “Output ON” should be “YES”. This means conditions are favorable for heating and the

controller should provide a call for heat.

u

The “Command” is between 0% and 100%. If the value is 0%, there is no call for heat.

u

The “Disabled” should be “NO”. If “Disabled” is “YES”, the Outside Air temperature is above

the Heat Lockout temperature. Change the Heat Lockout temperature setting in the Control

Variables menu, if necessary.

6.3 TEST GAS PRESSURES AND FLAME QUALITY

Turn the unit disconnect switch OFF while testing gas supply pressure.

With the unit disconnect switch OFF and the gas supply valve OFF, install a manometer at the

pressure tap located on the gas supply line.

Turn the gas supply valve ON and verify that the supply gas pressure is at least 5.0 InWC and

not higher than 13.5 InWC for natural gas or 11.0 InWC to 13.5 InWC for LP gas.

Record the gas pressure in the chart on next page.

Shut off the gas at the gas supply line, remove the manometer and replace the pressure tap

plug.

With the unit disconnect switch OFF, use the bleeder/pressure tap on the main inlet valve and

bleed the air from the supply pipe. When gas can be smelled, close the pressure tap and then

wait five minutes for the escaped gas to dissipate.

With the unit disconnect switch OFF, install the manometer on the pressure tap on the gas

manifold. If there are two pressure taps, either use two manometers or repeat the test as

necessary.

Turn the gas supply valve ON.

Turn ON the unit disconnect switch. When the unit disconnect switch is turned ON, it provides

high-voltage power to the gas heat module and will also produce 24 VAC needed for operation

of the gas valves and for switching between 1st stage and 2nd stage on two-stage valves.

The controller will not provide a call for heat until the controller is ENABLED. Gas valves are

Normally Closed (NC) until they receive an activating signal from the module controller.

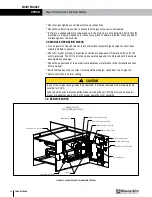

NOTE: There are

two gas shut-off

valves on the gas

heat module. One

is found in the mod-

ule, behind the module

cover. The second valve is

field-supplied and installed

and should have a bleeder/

pressure tap. See the

illustration in Section 5.8.2

of this manual.

OPERATION