43

1.800.627.4499

Integral Indirect Gas-Fired Heat Module

OPTION

6.6.4 Normal Operation

u

Turn on the unit disconnect switch. This will provide power to the gas heat module and also

boot-up the unit controller.

u

Enable the heating function by going to the controller Service Menu > Unit Type and set

Enable Heat to YES.

u

Enable the controller outputs by going to the Main Menu > Unit Enable. Set Unit Enable to ON.

u

Turn ON the gas valve on the gas supply line.

u

Set controller to desired temperature.

u

Verify if the heat module should run by viewing Unit Status > Heating screens. This will show

the currently sensed temperature, the heating setpoint and the Lockout Above setpoint.

6.6.5 Restarting a Heat Module

In the event that the gas supply is disconnected from the appliance or that the appliance must

be restarted:

u

Disable any call for heat by the controller by resetting the controller to disable the heating

function. In the controller, go to the Service Menu > Unit Type > Enable Heat and change the

status to OFF.

u

Disconnect all power to the appliance by turning the DOAS disconnect switch to OFF.

u

Turn the manual gas supply valve to the OFF position.

Restart the unit by:

u

Turn the main disconnect switch on the DOAS back to ON.

u

Turn the gas supply valve back to the ON position.

u

Enable the heating function of the DOAS by going to the Service Menu and enabling the

heating function.

u

Provide a call for heat to the gas heater module. In the controller, go to the Main Menu

> Control Variables > Heating and verify that the setpoint is greater than the ambient

temperature.

Note that when the appliance has received a call for heat, a purge cycle will begin. If the

appliance fails to light, the appliance will try three times to relight before going into a lockout

condition.

7.0 MAINTENANCE

Annual maintenance: This heat module should be inspected and serviced annually by a

qualified service agency to assure proper operation. Annual servicing of the module is normally

performed at the beginning of the heating season.

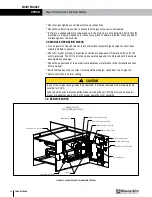

7.1 MODULE INSPECTION

Turn off all electrical power to the unit before inspection and servicing.

u

Visually inspect the condition of the heat exchanger tubes. Look for cracks, heat damage or

other deterioration in the tubes. Any heat exchanger tubes showing failure must be replaced

before the unit is placed back in service.

u

The burner assembly should be disassembled for inspection and cleaning.

u

Burners, igniters and flame sensors should be removed and cleaned. Check for obvious signs

of corrosion, accumulation of dirt and debris and any heat or water related damage. Any

damaged or deteriorated parts should be replaced before the unit is placed back in service.

u

Clean the draft inducer, vent ducts and vent terminal screens.

u

Check electrical wiring for loose connections or deteriorated insulation.

u

Check the attachment point of the module to the cabinet or ducts to verify they are air tight.

NOTE: The process

described here is

known as a "hard

restart". It resets

both the unit controller and

the heat module control-

ler to their programmed

conditions. It is generally

used only after the heat

module goes into a lockout

condition.

NOTE: It may be

necessary to use

a “borescope” to

properly inspect the heat

exchanger tubes.

MAINTENANCE