1.800.627.4499

42

Integral Indirect Gas-Fired Heat Module

OPTION

u

Lockout Above. Select an outdoor air temperature that can be used to disable the gas heat

module. The Lockout Above temperature should be selected based on the Outdoor Air

temperature that will no longer require heating of the Occupied Space.

u

KP. This stands for Proportional Gain. The factory setting is 1. This represents how

aggressively the gas heater will respond to a need for more (or less) heat. In normal

operation, the most cost-effective and most comfortable response to a need for heat is for

the gas heater to ramp up smoothly until the heat setpoint is met. Example: the controller

senses that there is a need for a 2 degree temperature rise in the Occupied Space. With a KP

setting of 1, the controller will slowly ramp up the Call for Heat command to the gas heater. If

the user finds this response to be too slow, the KP setting can be increased. If the KP setting

is raised too high, the heater will heat up rapidly and over-shoot the desired temperature. See

the

DN Integrated Controller User Manual

for further information on selecting a KP value.

u

Ti. This stands for Time Integral. The factory setting is 30. This refers to the frequency that

the KP signal is monitored in order to modify the KP signal. See the

DN Integrated Controller

User Manual

for further information on selecting a Ti value.

See Heating Screen 2, Section 6.6.3 of this manual.

NOTE: The process

of setting the KP

and Ti setpoints is

part of controller tuning.

Controller tuning is a

necessary part of commis-

sioning the unit but is not

needed to verify correct

operation of the unit.

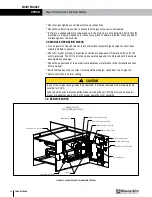

Unit Status

Setpoint

72.0˚ F

70.5˚ F

Command

100%

HEATING

Output ON

YES

Disabled

YES

Shows that the Call for Heat is being disabled

because of the Lockout Above setting

Shows that the controller wants to put out a 100%,

or 10 VDC Call for Heat.

Shows that the controller senses that the current

temperature is lower than the setpoint.

Shows that the controller is supposed to maintain

the setpoint of 72˚ F.

IMPORTANT

Controllers that put out a variable Call for Heat require a means of anticipating the needed

control signal. Heat modules in DN-Series units are all variable output and require a 0 - 10

VDC control signal.

The variable control signal uses a PI loop to make the variable signal respond properly to a

Call for Heat. There are two factors that produce variations in the control signal that the heat

module responds to. The Proportional Constant (KP) determines how aggressively the signal

will respond to a need for heat. As soon as the controller senses a difference between the

current temperature and the setpoint, the controller immediately puts out a Call for Heat. If

the KP setting is too high, the command signal and temperature will over-shoot the setpoint.

If the KP setting is too low, it takes too long for the heat module to satisfy a need for heat.

In order to reduce the over-shoot, the variable command signal needs a means of damping

the signal that results from the KP setting. The controller also uses what is known as a Time

Integral (Ti), which is a periodic sampling of the remaining error. The sampling then modifies

the command signal, smoothing the KP signal response. If the Ti sampling occurs too often,

it slows the rate of command signal increase. If it doesn't occur often enough, the command

signal will still over-shoot the setpoint.

The process of setting the KP and Ti values is "controller tuning". Tuning the controller is

normally the last step in the process of commissioning a DN-Series unit. Information on

setting KP and Ti is found in the

DN Integrated Controller User Manual

.

OPERATION